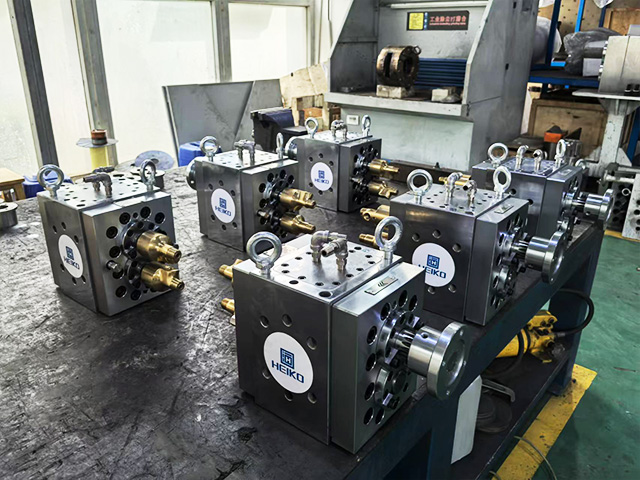

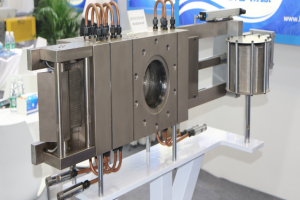

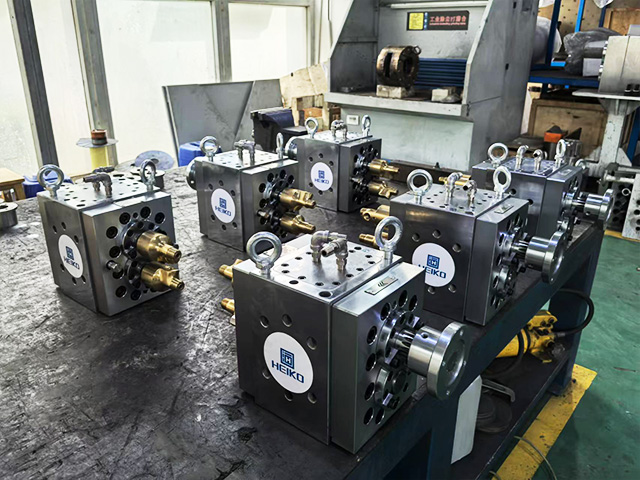

As a critical precision core component in plastic wire drawing production lines, melt metering pumps leverage the positive displacement principle of positive displacement gear transmission to provide precise, stable, and homogeneous melt delivery for the production line. They fundamentally resolve flow and pressure instability issues caused by extruder screw pulsation and material temperature/viscosity variations. By comprehensively optimizing the filament drawing process across three dimensions—filament quality, production efficiency, and equipment maintenance—these pumps flexibly accommodate multiple materials (PE/PP/PVC) and diverse filament specifications (round, flat, multi-strand). Their specific functions can be summarized as follows:

Precise Metering for Stable Flow

Enables accurate, quantitative melt delivery with minimal flow deviation. Effectively counteracts process fluctuations from extruder operation and material properties, ensuring constant melt supply to the die. This fundamentally guarantees uniform filament diameter and weight, eliminating appearance defects like thickness variations and laying the foundation for high-quality filament production.

Stable Pressure, Buffering, Defect Prevention: It establishes and continuously maintains constant melt pressure at the die, efficiently buffering periodic pressure pulsations generated by the extruder screw's operation. This prevents quality issues like thread breakage, rough threads, and bubbles caused by sudden pressure changes, ensuring continuous and stable operation during high-speed drawing and cooling processes. It significantly enhances the surface finish and internal mechanical strength of the filament.

Shear Mixing and Homogenization

Precise gear meshing within the pump chamber achieves multiple shearing actions, thorough agitation, and uniform mixing. This effectively reduces internal temperature gradients, minimizes trapped impurities and bubbles in the melt, and promotes uniform dispersion of molecular chains. These enhancements further elevate the intrinsic quality of the filament, fully meeting the stringent quality requirements of downstream processes like braiding and winding.

Load Reduction for Enhanced Efficiency and Equipment Protection: Actively shoulders primary pressure loads during melt conveyance, substantially reducing extruder screw backpressure and torque. This minimizes wear on critical equipment components, lowers energy consumption per unit output, and effectively extends the service life of core equipment like extruders. Simultaneously, it enables production lines to operate at higher speeds, reduces unplanned downtime frequency, decreases scrap generation rates, and comprehensively boosts overall production efficiency and economic benefits.

Flexible Adaptability Across Scenarios: Melt output flow exhibits a strict linear relationship with pump speed. Variable frequency speed control enables rapid, precise adjustment of melt supply, drastically shortening process changeover and debugging times for different filament specifications and materials. It also flexibly interfaces with extruders, screen changers, and various mold specifications, accommodating multi-material and multi-category filament production needs. This significantly boosts production line capacity utilization and applicability while enhancing operational flexibility.

Overall, the application of melt metering pumps serves as the critical foundation for achieving high-precision, high-stability, high-efficiency, and high-yield continuous production in plastic wire drawing lines. It is also the core configuration for enhancing the market competitiveness of wire drawing products and driving the quality improvement and efficiency upgrades of production lines.