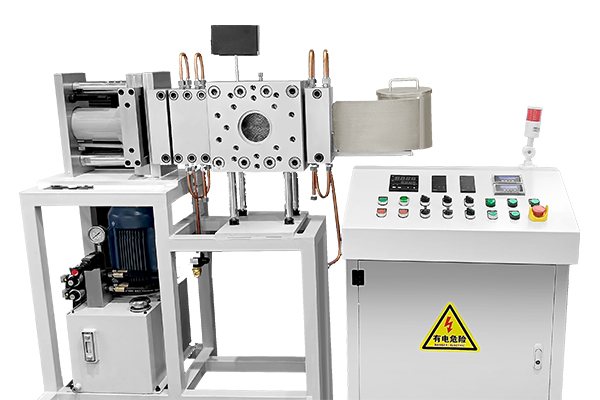

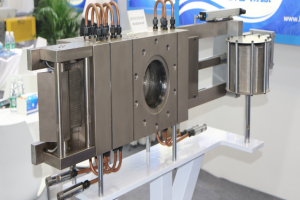

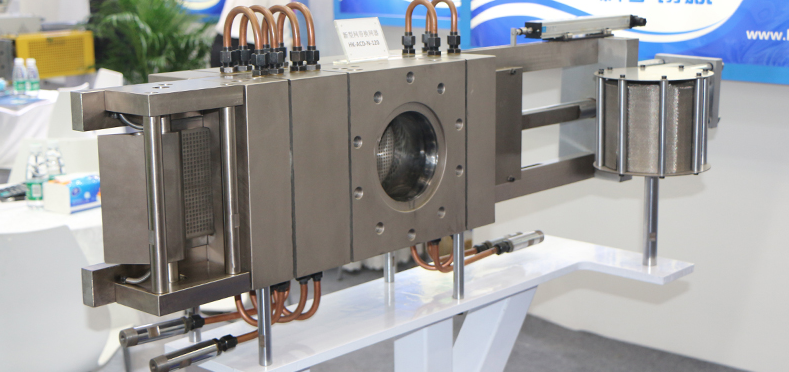

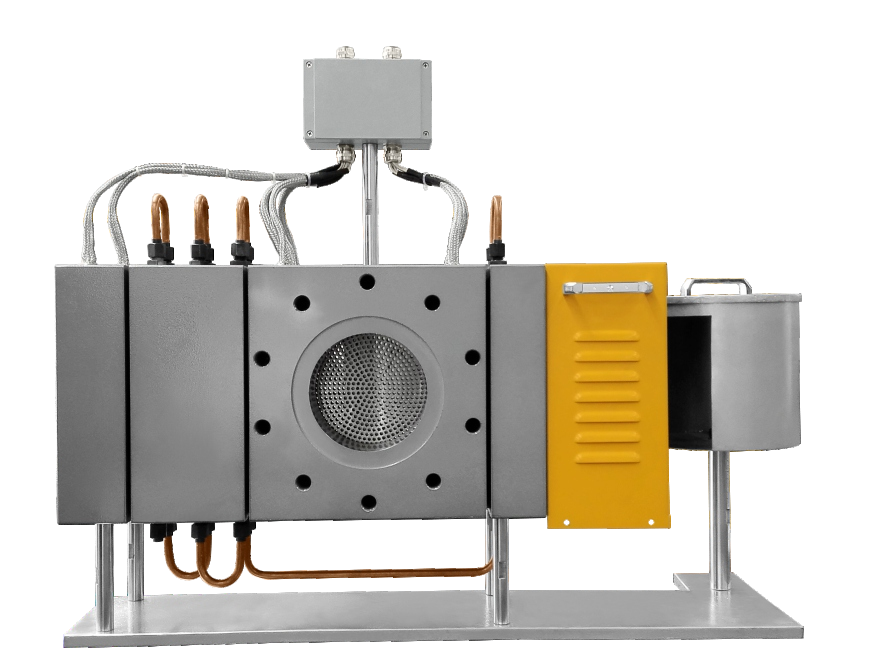

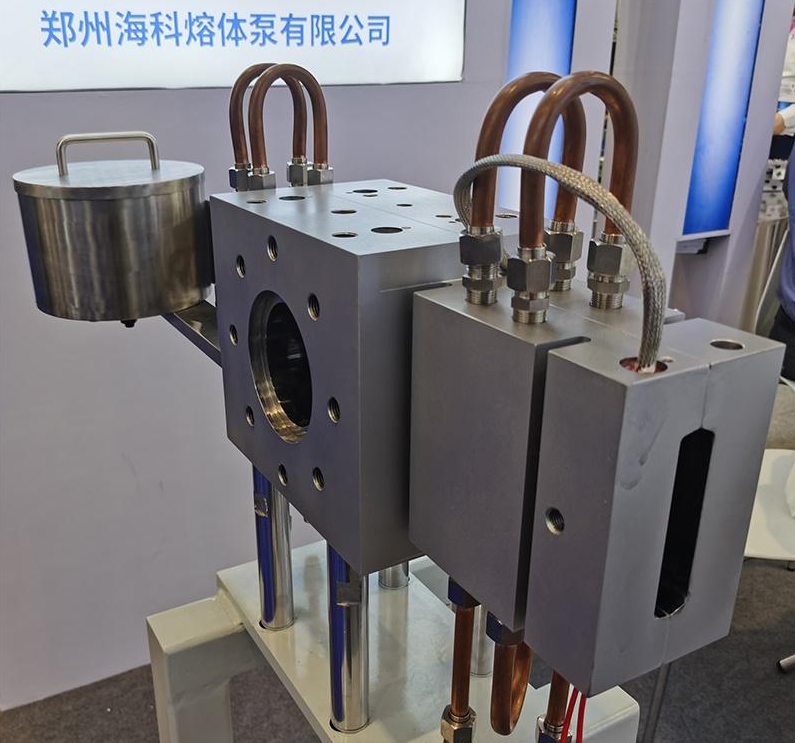

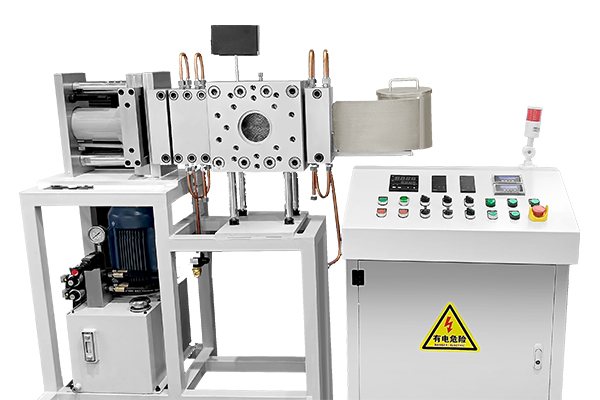

The Belt-Type Fully Automatic Screen Changer is a continuous production equipment for melt filtration. Its core function is to precisely remove impurities such as carbonized particles and metal shavings from molten materials while ensuring stable melt pressure and flow rate, achieving zero production downtime. Its operating principle relies on the coordinated operation of automated control and physical mechanisms. The core process can be divided into five key stages: trigger activation, heating-assisted migration, belt transmission, cooling sealing, and circulation standby, as detailed below:

Trigger Activation

The screen change program is initiated through an automatic detection mechanism, with core trigger conditions falling into two categories: pressure-triggered activation occurs when melt pressure at the feed inlet rises to a preset threshold (indicating screen clogging due to impurity retention); time-triggered activation occurs when the operating duration reaches a preset interval. Upon fulfillment of either condition, the control system immediately activates the actuator to initiate the screen change process.

Heating-Assisted Migration and Screen Belt Drive

The control system then activates heating components at the outlet (e.g., electric heating rods) to precisely heat localized sections of the melt channel. This reduces melt viscosity, facilitating screen belt movement. Subsequently, no external force is required—the melt's own pressure slowly propels the screen belt, simultaneously conveying surface-trapped impurities out of the filtration chamber to ensure uninterrupted material flow.

Cooling Seal and Standby Circulation

Upon the mesh belt exiting the filtration chamber, the outlet water cooling system activates immediately. Circulating cooling water rapidly cools residual melt within the channels, causing it to solidify into a dense seal structure that completely prevents melt leakage. Simultaneously, melt pressure at the inlet drops back to normal range. The control system then halts heating and maintains cooling until the seal stabilizes. When conditions for the next screen change are met, the system restarts the circulation process, ensuring continuous constant-pressure production.

Through automated control and precise coordination with melt pressure, this process achieves seamless transition between continuous screen belt movement and filtration states. It maintains stable material flow and constant pressure throughout, effectively safeguarding production continuity and product quality.