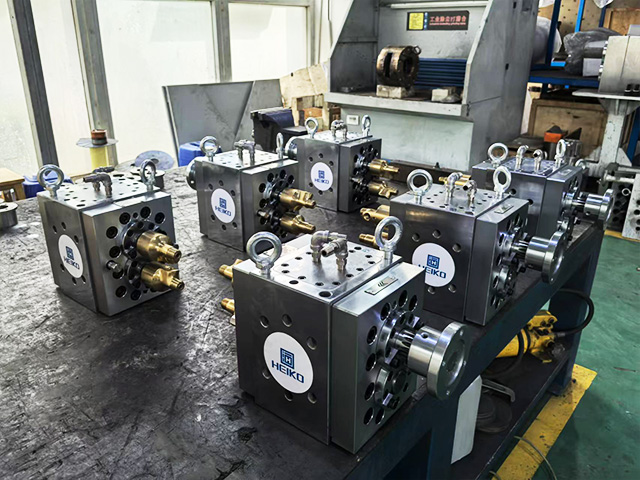

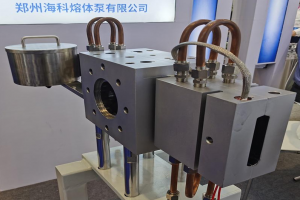

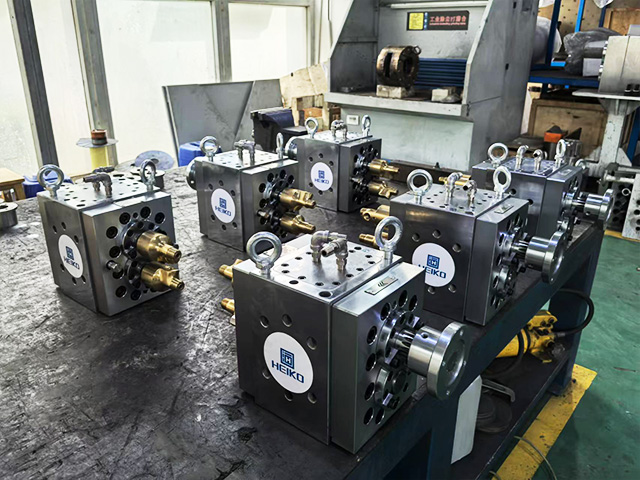

The PET strapping tape metering pump (also known as a melt pump) serves as the core critical equipment in plastic strapping tape production lines. Primarily used for the precise delivery, metering, and stable control of PET (polyethylene terephthalate) melt material in a high-temperature molten state, it acts as the pivotal link between the extruder and the die head. This pump ensures the quality of strapping tape products and enhances production efficiency. Its operational stability and metering precision directly determine the output quality and economic efficiency of the entire production line.

Precise Metering and Flow Control: As a positive displacement conveying device, the melt pump achieves quantitative delivery of the melt through the synchronized rotation of a pair of high-precision meshing gears. Its output flow exhibits a strict linear relationship with pump speed, unaffected by system pressure fluctuations. Paired with a precise variable-frequency speed control system, the rotational speed can be flexibly adjusted to precisely regulate melt delivery volume. This ensures high consistency in the thickness, width, and weight per unit length of PET strapping, strictly controlling thickness tolerance within ±1%. It effectively reduces scrap caused by dimensional deviations and significantly improves product yield rates.

Stabilizing System Pressure: The periodic motion of the upstream extruder screw can cause melt pressure fluctuations, adversely affecting product forming quality. The metering pump effectively buffers these fluctuations, maintaining pressure variations at the die outlet within ±1%. This ensures constant melt system pressure, preventing forming defects such as surface wrinkling, uneven thickness, burred edges, and breakage caused by unstable pressure. It guarantees continuous and stable production line operation while reducing unplanned downtime losses.

Enhancing Production Efficiency and Energy Savings: Metering pumps independently handle the core tasks of establishing and maintaining system pressure, significantly reducing the working load and back pressure on the extruder screw. This eliminates the need for the extruder to operate under high-pressure, high-temperature overload conditions. Practical data indicates that integrating metering pumps reduces production line motor energy consumption by 15%-30%. Concurrently, extruder output efficiency improves, boosting overall production line output by 15%-20%. This achieves dual benefits of high-efficiency production and energy conservation.

Promoting Melt Homogenization: High-temperature PET melt undergoes shearing, compression, and agitation within the pump housing via gear action. This process eliminates internal temperature gradients and composition inconsistencies, resulting in more uniform melt temperature distribution and thorough mixing of PET molecular chains. Consequently, the mechanical properties of the final packaging straps are enhanced, improving tensile strength, toughness, and impact resistance. This ensures the straps resist breakage during use and meet the load-bearing demands of securing various heavy objects.