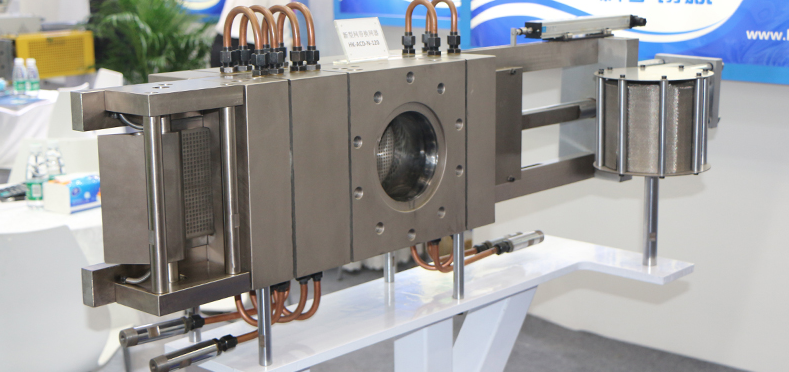

The belt-type fully automatic screen changer is widely adopted across multiple scenarios due to its high efficiency and advanced features, primarily including:

High-quality, long-process product manufacturing: Such as laminated films, cast films, various drawn fibers, sheets, films, chemical fibers, and other products. These items demand high quality and continuous production processes, which the belt-type fully automatic screen changer effectively fulfills.

High-Precision Product Manufacturing: In the production of precision goods demanding strict control over pressure fluctuations, the belt-type automatic screen changer maintains stable pressure during screen changes, ensuring consistent product quality.

Production of Multiple Raw Materials: It is suitable for processing various raw materials including PP (polypropylene), PE (polyethylene), ABS (acrylonitrile butadiene styrene copolymer), PS (polystyrene), PMMA (polymethyl methacrylate), demonstrating strong versatility and adaptability.

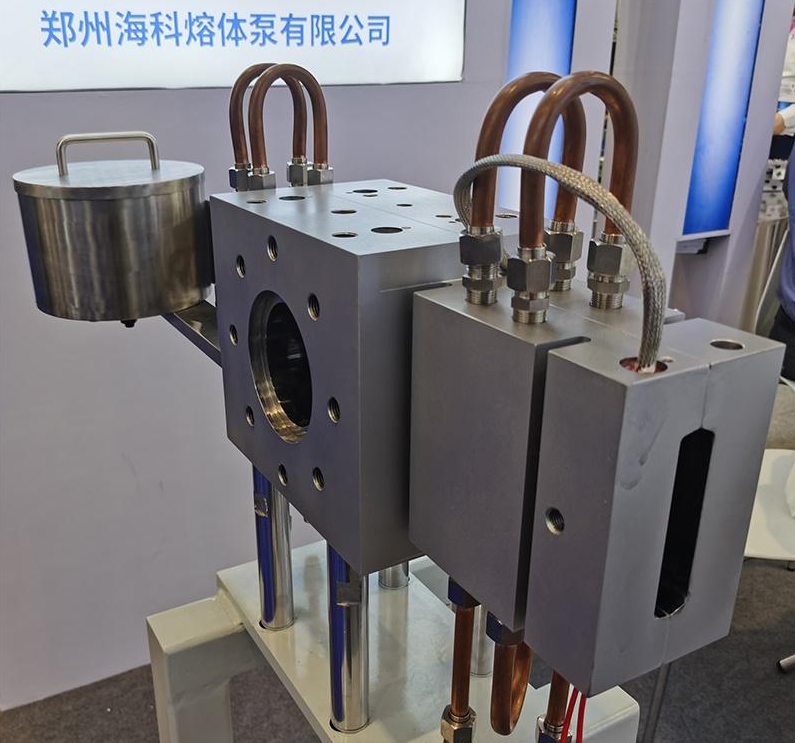

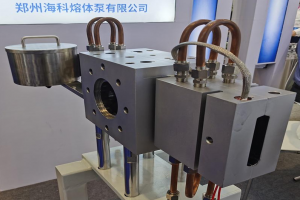

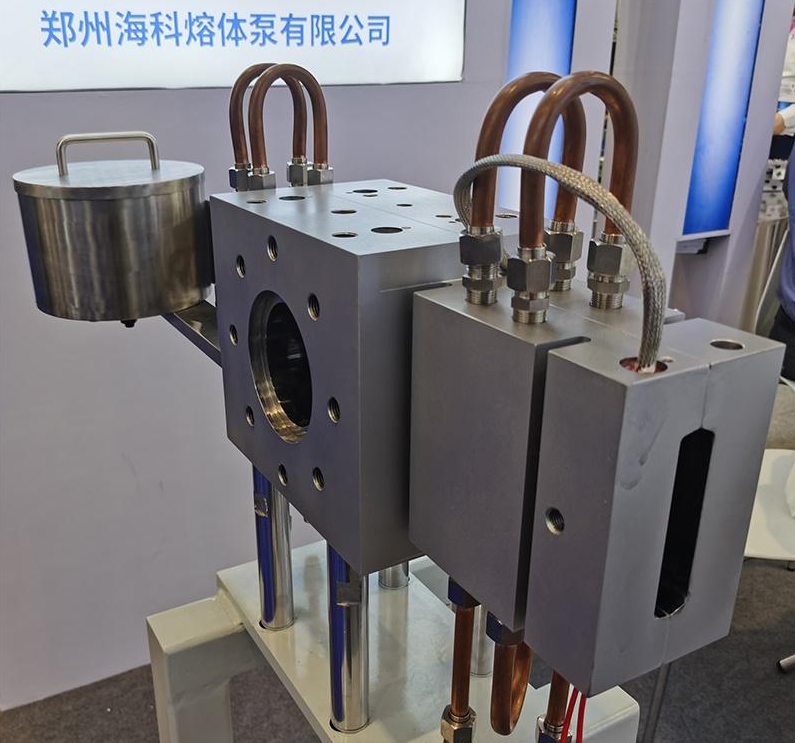

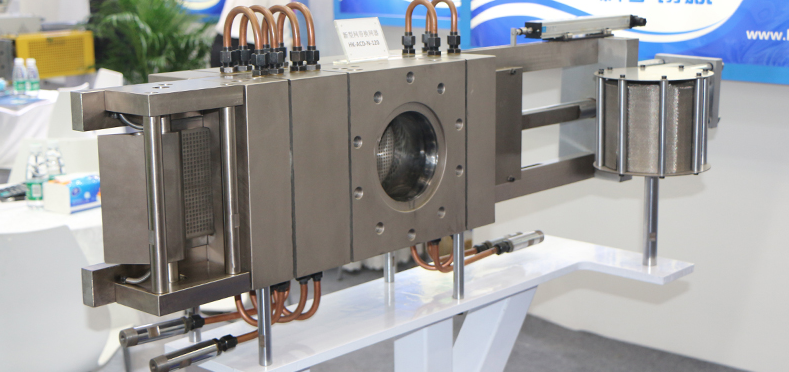

Additionally, the mesh belt-type fully automatic screen changer offers advantages including: fully automatic mesh feeding without production stoppage, smooth and stable screen changing without fluctuations, reduced material waste and environmental pollution, customizable screen length, innovative structure with easy installation, extended service life, and convenient maintenance and cleaning. These features enable it to play a vital role across various industrial sectors requiring efficient, continuous, and stable production.