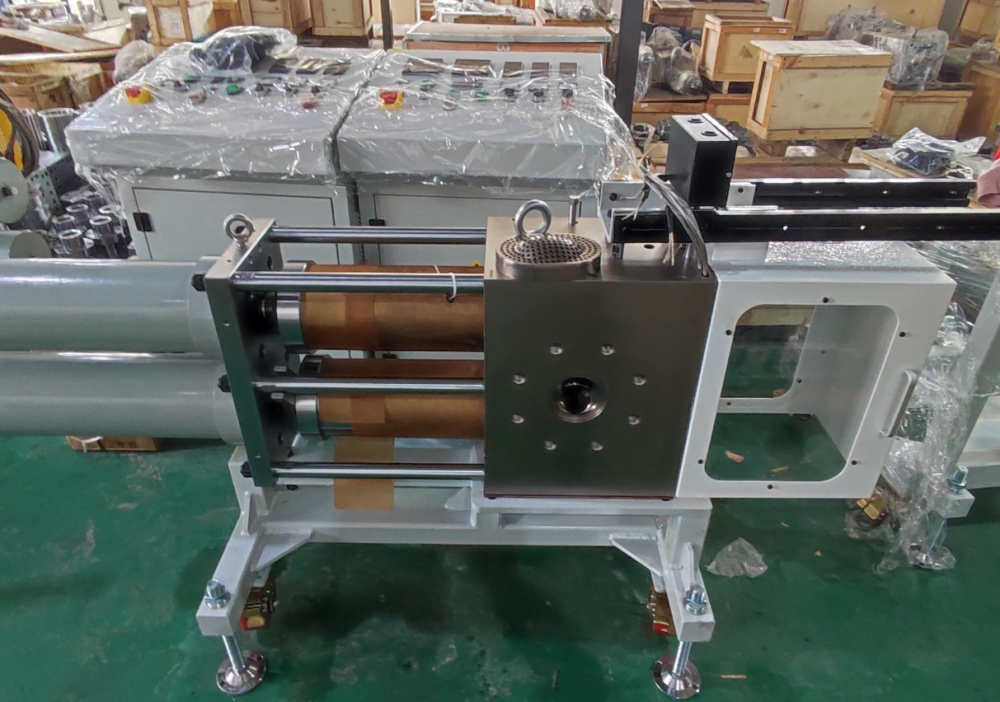

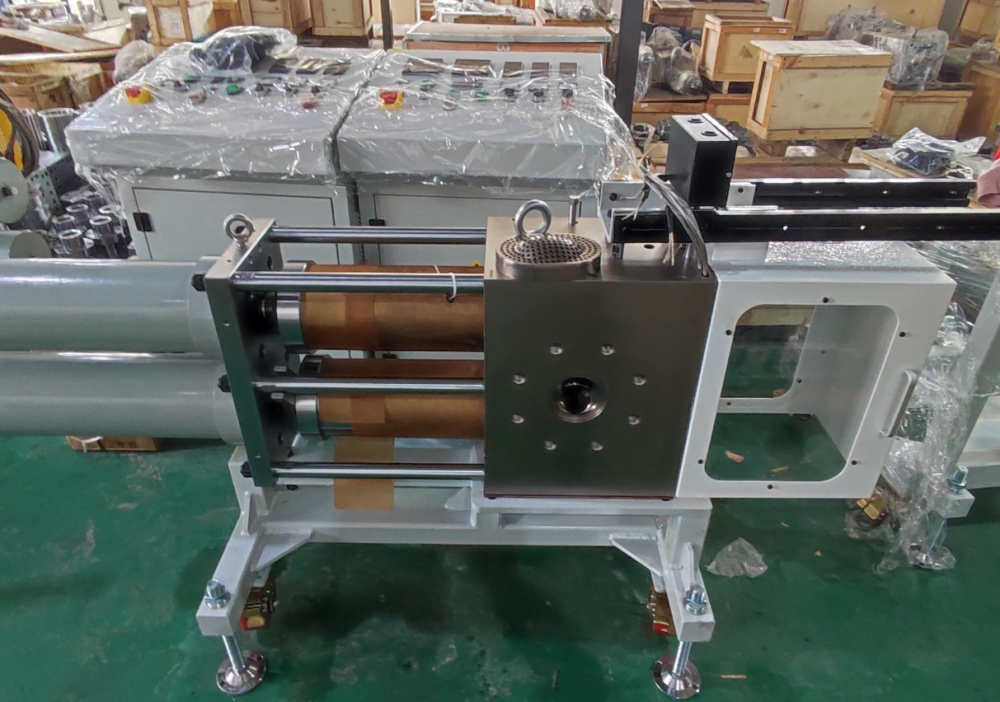

Non-Stop Screen Changing: Dual-piston alternating screen change design—one cylinder filters while the other replaces simultaneously, ensuring zero production downtime and over 50% efficiency boost!

Large Filtration Area: Offers 4-5 times the filtration area of conventional changers within the same volume, effortlessly handling high-impurity melts and significantly reducing changeover frequency!

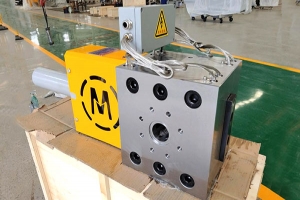

High-Temperature & High-Pressure Resistance: Constructed from alloy steel/corrosion-resistant materials, withstands temperatures up to 400°C and easily handles pressure from high-viscosity materials!

Additional Advantages:

Strong Process Adaptability: Fully compatible with conventional plastics (PE, PP, PVC) and specialty materials. Handles high-filler (≤60%), high-temperature (≤400°C), and high-pressure (≤35MPa) conditions with ease!

Optimized Degassing & Feed Introduction: Integrated degassing structure eliminates bubble pockets; scientifically designed feed system dramatically boosts filtration efficiency!

Applications: Industrial production lines requiring continuous filtration and high-impurity processing, such as plastic extrusion and chemical fiber spinning!