As core equipment for melt filtration and impurity separation, screen changers are widely used in the melt conveying, molding, and modification processes of various polymer materials. Their efficient filtration performance and stable operation make them essential across nearly all production stages in the plastics, rubber, hot melt adhesive, and related industries. Specific application scenarios include:

I. Direct Extrusion Molding Processes

This represents the most fundamental and core application area for screen changers, suitable for the extrusion molding production of diverse plastic products. Whether producing rigid items like sheets, plates, pipes, or profiles; film products such as blown film, cast film, or laminated film; or processes like fiber drawing, strapping extrusion, or pelletizing, screen changers precisely filter impurities and carbonized particles from the melt. This not only prevents mold runner blockages and ensures continuous extrusion but also enhances product surface finish and intrinsic quality while reducing defect rates caused by impurities.

II. Compounding Modification and Masterbatch Production Processes

Screen changers play a critical role in the production of color masterbatches, functional masterbatches, plastic alloys, and filled modified materials. These processes often involve high-speed mixing and melting of multiple components such as resins, pigments, additives, and fillers, where impurities like filler dust and agglomerated additive particles can easily contaminate the melt. Screen changers effectively intercept these contaminants, ensuring a uniform and stable melt system. Particularly in pelletizing processes like underwater pelletizing, water-ring pelletizing, and air-cooled pelletizing, integrating screen changers significantly enhances pellet appearance and purity, meeting the production requirements for high-end modified materials.

III. End-of-Line Process for Raw Material Polymerization

In polymerization production lines for materials like polyester, polyolefins, and polyurethane, screen changers are critical equipment for ensuring raw material purity. After polymerization, the melt may contain residual impurities such as catalyst residues, unreacted monomer particles, and coke deposits shed from reactor walls. By installing a screen changer at the polymerization reactor outlet, the melt undergoes high-precision filtration. This ensures the quality of feedstock for subsequent pelletizing or molding processes, laying a solid foundation for downstream product manufacturing.

IV. Recycled Plastic Processing

Screen changers are indispensable core equipment in the recycling of post-consumer materials, production waste, and scrap. Recycled materials typically contain significant impurities, such as sand, paper, and metal fragments in woven bag recyclates, or ink spots and foreign particles in waste films. Without effective filtration, these contaminants severely compromise the quality and processability of recycled materials. Screen changers efficiently separate these impurities, enhancing the cleanliness of recycled materials and enabling high-value circular utilization of recyclates, aligning with industry trends toward environmental protection and sustainable development.

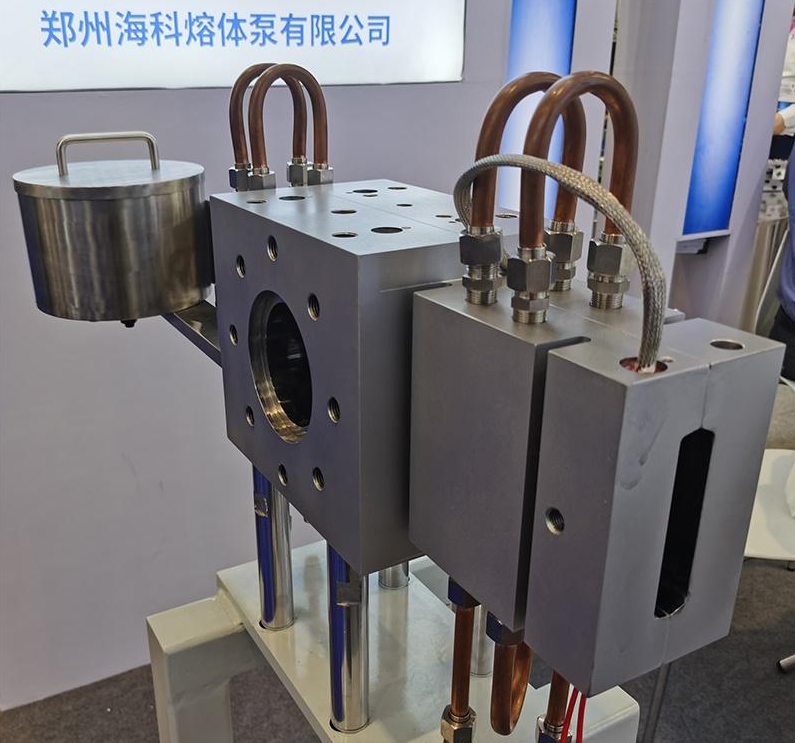

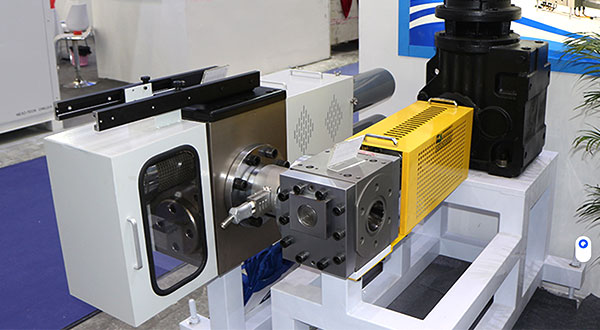

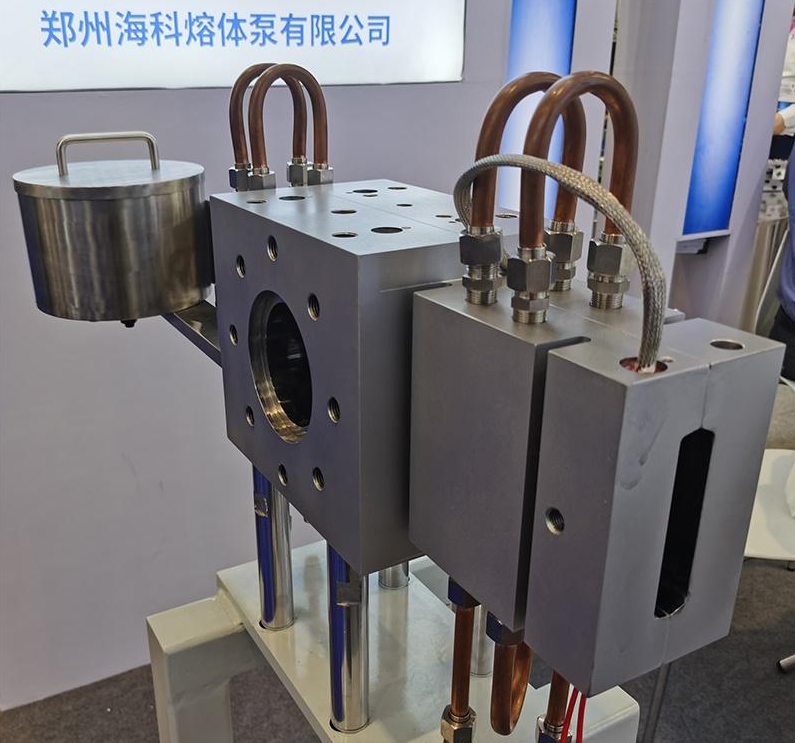

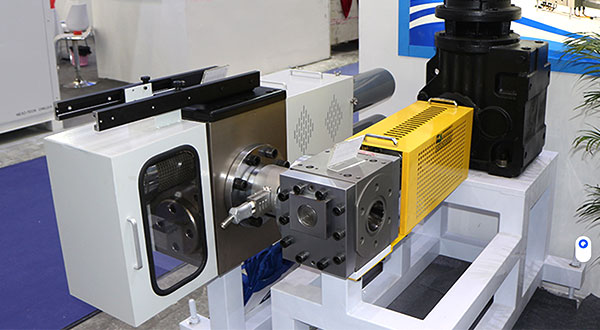

Take Zhengzhou Heiko's screen changers as an example. Their products demonstrate exceptional adaptability across various scenarios, thanks to structural design advantages and robust manufacturing processes. The equipment seamlessly integrates with upstream and downstream machinery like extruders, melt pumps, and reactors, withstanding demanding high-temperature and high-pressure production environments while supporting continuous, long-term stable operation. Whether for conventional plastic processing or specialized applications involving heat-sensitive materials and high-viscosity melts, Zhengzhou Heiko's screen changers deliver customized filtration solutions tailored to diverse operational requirements, ensuring efficient production line performance across industries.