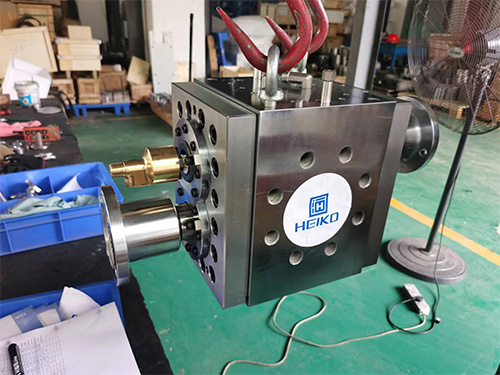

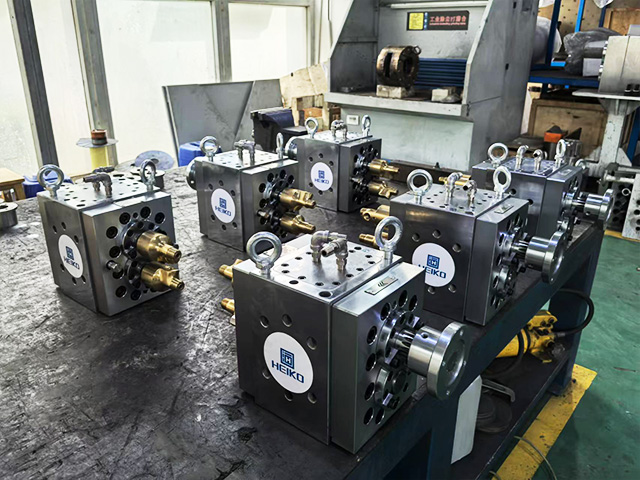

The small laboratory extruder melt pump is a precision auxiliary device commonly used in polymer material research and development. It is primarily employed for small-batch melt transfer, pressure stabilization, and flow metering applications.

At its core, the small laboratory extruder melt pump functions as a gear pump. It achieves melt transfer through a pair of meshing gears rotating within a sealed chamber. When the drive gear rotates the driven gear, negative pressure forms in the suction chamber, drawing material from the upstream extruder. The meshing gears then forcefully push the material toward the outlet, generating stable high pressure. Flow rate is linearly adjusted by precisely controlling the gear rotation speed.

Features

High-Precision Metering: Enables accurate control of melt flow rate with precision up to ±0.5%, ensuring experimental data accuracy and repeatability.

Flow Stability: Provides consistent melt delivery, minimizing experimental variations caused by flow fluctuations while maintaining outlet pressure within narrow tolerances.

Compact Design: Small footprint ideal for space-constrained laboratory environments, featuring straightforward installation and operation.

Material Versatility: Pump body and components utilize multiple corrosion-resistant and wear-resistant materials, such as tool steel and high-temperature alloys, accommodating materials with varying chemical properties and extending service life.

Primary Applications

Polymer Extrusion Molding: In small extruders, precisely delivers polymer melt to molds for producing various shaped products.

Simulation of New Material Melting Characteristics Testing: Assists researchers in precisely controlling melt flow rate and pressure to evaluate the melting properties of new materials under different processing conditions.

Formulation and Process Optimization: Enables precise measurement of melt flow rate to study the rheological behavior of materials under varying formulations and process parameters, thereby optimizing formulations and processes.

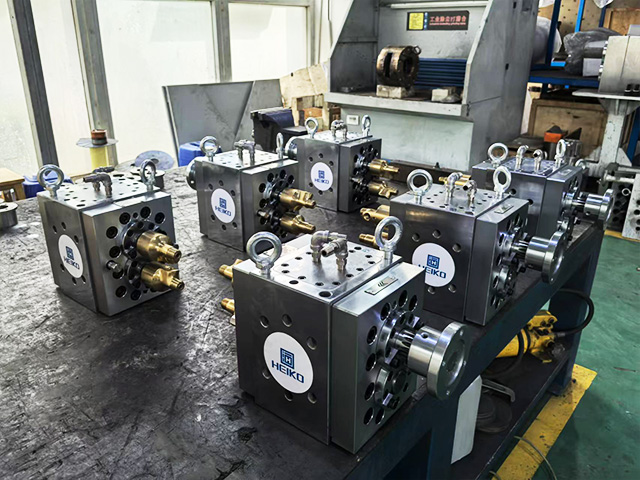

Heiko melt pumps feature high-temperature alloy gears and pressure closed-loop control technology, delivering stable performance and outstanding industrial application results. Their product line also includes compact models suitable for laboratory use.