A melt pump is a device used for conveying high-temperature, high-viscosity melts, widely applied in the processing of polymer materials such as plastics, chemical fibers, and rubber. When selecting a melt pump, the following aspects should be considered:

I. Melt Pump Product Structure

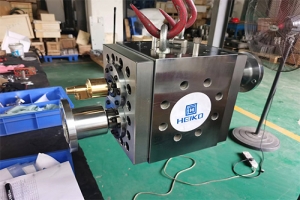

The melt pump primarily consists of the pump body, pump shaft, bearings, and seals. The pump body is manufactured from high-temperature alloys or high-strength stainless steel, offering characteristics such as high-temperature resistance, corrosion resistance, and high strength. The pump shaft typically employs a hollow design to transmit greater torque and higher rotational speeds. Bearings utilize high-speed, heavy-duty types capable of withstanding substantial axial and radial loads. Seals employ mechanical seals or packing seals to effectively prevent melt leakage.

II. How to Select a Melt Pump

When selecting a melt pump, consider the following factors:

1. Pump Capacity: Including maximum torque, maximum displacement, and maximum rotational speed.

2. Pump Materials: The materials of the pump body, shaft, bearings, and seals directly impact the melt pump's service life and performance.

3. Sealing configuration: Mechanical seals or packing seals directly affect leakage levels and sealing effectiveness.

4. Drive method: Motor-driven or hydraulic-driven options should be selected based on specific operational requirements.

5. Control system: Must ensure stable pump operation and provide safety protection.

III. Product Advantages of Melt Pumps

Melt pumps offer the following advantages:

1. High-temperature, high-viscosity melt conveyance, suitable for transporting various polymer materials.

2. High conveyance efficiency and stable pressure, significantly reducing production energy consumption.

3. Extended service life and low maintenance costs, substantially minimizing downtime and replacement expenses.

4. Advanced sealing technology effectively prevents melt leakage, ensuring a clean production environment.

5. Compatible with multiple sensors and automated control systems to enable intelligent production and management.

IV. Melt Pump Application Scenarios

Melt pumps are widely used in polymer material processing sectors such as plastics, chemical fibers, and rubber—including plastic product manufacturing, chemical fiber spinning, and rubber calendering. As core equipment in these fields, melt pumps directly impact product quality and production stability. Therefore, selecting a melt pump must align with actual production requirements, ensuring capacity and material compatibility to guarantee smooth operations and enhanced efficiency. Simultaneously, strict adherence to operating procedures for maintenance and upkeep during operation is crucial to guarantee the pump's longevity and operational stability.

In summary, as vital equipment in polymer material processing, selecting the appropriate melt pump is critical for ensuring uninterrupted production and enhancing efficiency. When choosing a melt pump, comprehensive consideration and comparative analysis of factors such as product structure, materials, sealing configurations, and control systems are necessary to identify the pump best suited to specific production requirements.