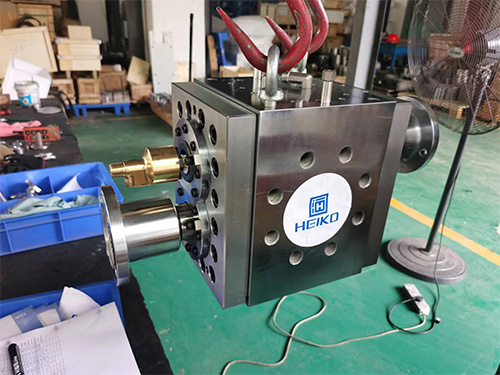

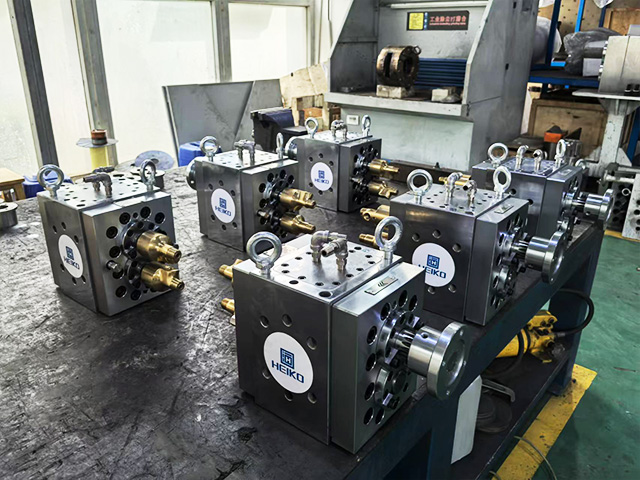

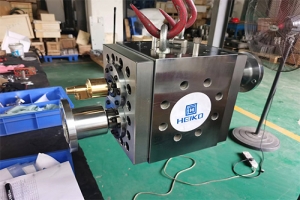

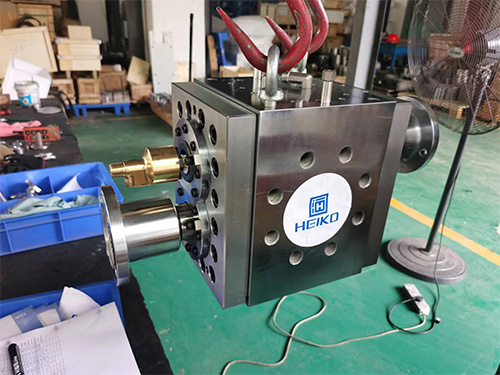

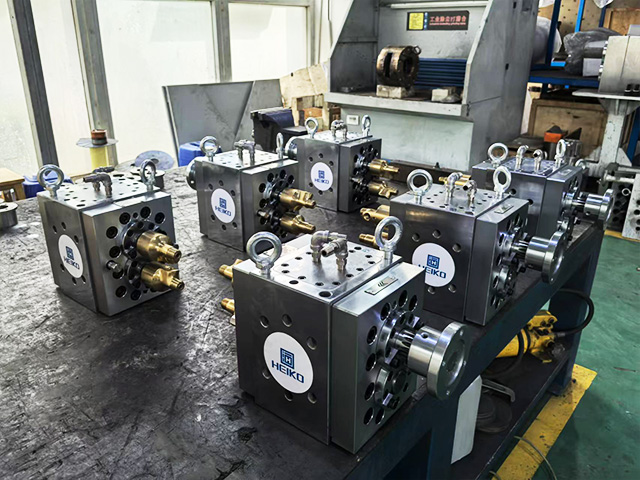

External gear melt gear pump for PP meltblown nonwoven production lines. Core function: melt pressurization, stabilization, and metering between the extruder and die head to ensure uniform web formation and precise basis weight. Commonly used in medium-to-low capacity PP meltblown lines (approx. 100–300 kg/h).

Working Principle and Structure

Principle: External positive displacement. As gears rotate, melt enters the gear cavities and is conveyed to the discharge zone. During meshing, the melt is extruded. Flow rate is strictly proportional to rotational speed, with pressure fluctuations controllable within ±0.5MPa.

Core Structure: Pump body, drive/driven gears, sliding bearings (self-lubricated by melt), sealing assembly, heating/insulation system, drive unit (motor + gear reducer + coupling).

Key Features and Advantages

Precise Metering: Flow accuracy ±1%, weight deviation ≤±2g/㎡, meeting medical-grade meltblown fabric requirements.

Strong Pressure Stabilization: Significantly reduces extruder pressure pulsation, maintains stable outlet pressure, minimizes spinneret clogging and fiber breakage.

Energy Efficiency & Productivity: Transfers pressure load from the extruder, enabling high-speed screw extrusion. Increases production capacity by 10%–20% while reducing energy consumption by 8%–15%.

Extended Lifespan: Melt-lubricated bearings + wear-resistant materials minimize abrasion, prolonging the service life of both the extruder and pump.

Easy Control: Linear flow characteristics support PLC integration, enabling remote speed adjustment and closed-loop pressure control.

Applications and Precautions

Suitable for: PP meltblown nonwoven fabrics (medical, protective, filtration materials), especially small-to-medium capacity (100–300 kg/h) production lines demanding high precision and stability.

Precautions: Strictly prohibit dry running without melt. Prevent metal contaminants from entering the pump housing by installing a high-efficiency screen changer upstream. Maintain melt viscosity between 1000–10000 Pa・s to prevent overload.