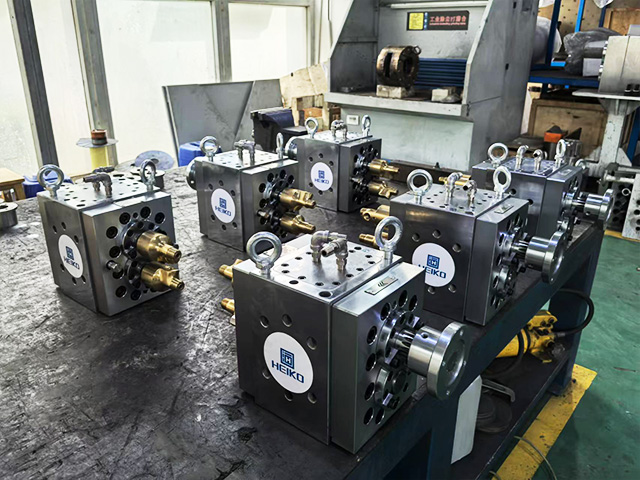

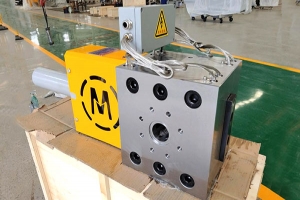

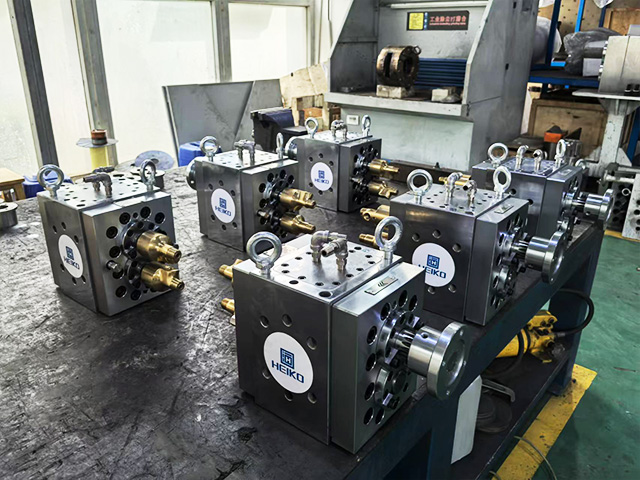

The extrusion melt pump is a widely used conveying device in the plastics industry. Its primary function is to pressurize and stabilize the high-temperature plastic melt from the extruder, delivering it steadily to the extrusion die. This eliminates screw pulsation in the extruder and enhances product quality.

Functions of Extrusion Melt Pumps

Significantly enhances die head pressure stability, improving product quality;

Achieves near-linear flow output for easy control;

Increases extrusion volume, boosting production output;

Reduces extruder load, conserving energy and lowering costs.

Features of Extrusion Melt Pumps

Optimized melt flow channel design: Eliminates dead zones within the flow path, minimizes polymer residue, and improves product quality;

Optional integrated flow channels: Suitable for fluid cooling to accommodate more precise and rapid temperature control systems; also applicable for thermal fluid heating;

Enhanced gear parameter design: Precise displacement calculation ensures stable output pressure for precision extrusion applications;

Wide viscosity range compatibility: Utilizes varied sealing methods for low-to-ultra-high viscosity conditions;

Multiple mounting configurations: Accommodates customized user requirements;

High-precision manufacturing and superior heat treatment: Ensures greater accuracy and durability.

Extrusion Melt Pump Parameters

Conveyed Medium Viscosity: 1~40,000 Pa·s (1000~40,000,000 cP)

Suction pressure: Vacuum (-0.00 to -0.03 MPa) to 30 MPa

Discharge pressure: 0 to 40 MPa

Differential pressure: ≤325 MPa

Operating temperature: ≤350°C

Heating method: Electric heating