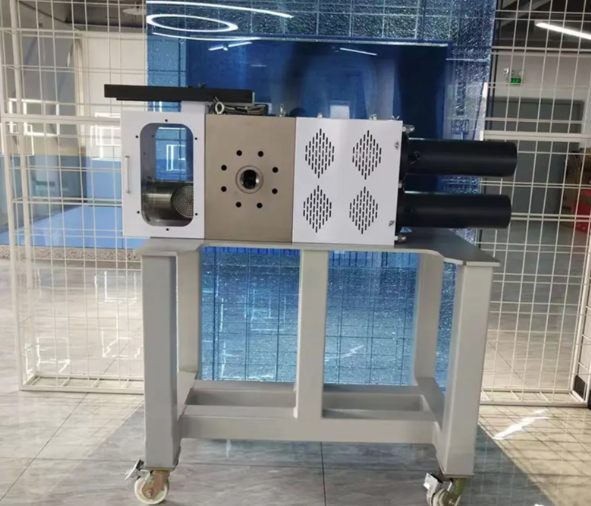

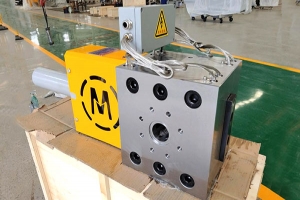

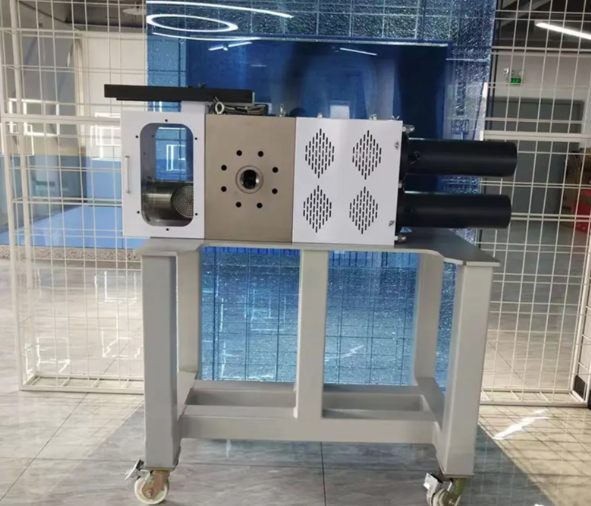

This equipment serves as the core auxiliary machinery in plastic recycling pelletizing production lines. Specifically engineered for recycled materials (PE/PP/ABS/PA, etc.) with high impurity levels and high melt viscosity, it enables non-stop screen changes through alternating operation of dual columns. This eliminates production interruptions, preventing material waste and efficiency losses, and meets the continuous production demands of recycling pelletizing extruders.

Core Features (Tailored for Plastic Recycling Pelletizing Applications)

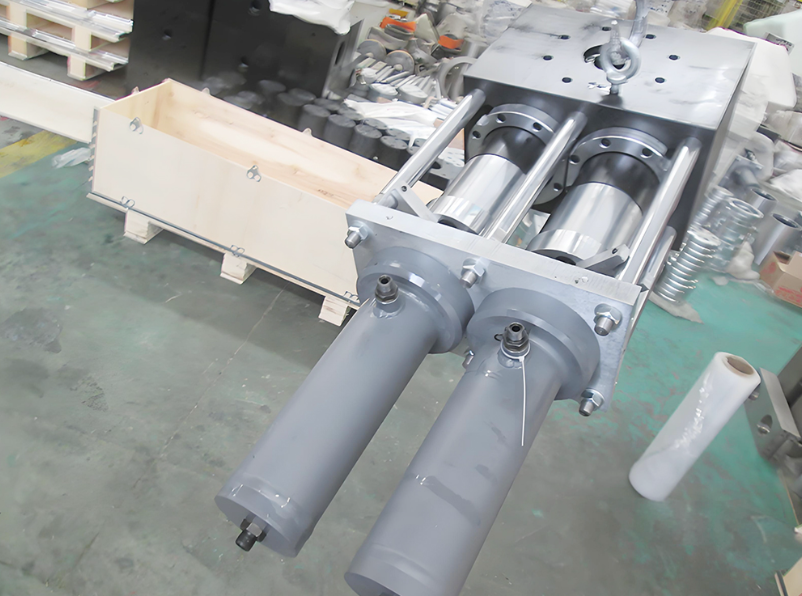

Non-stop Screen Changing, Zero Production Downtime: Dual-column structure houses independent filter chambers, enabling hydraulic-driven rapid switching (≤3 seconds). Melt pressure fluctuation during changeover remains ≤0.5MPa, maintaining extruder speed and pellet quality while resolving frequent clogging and screen replacement issues common with recycled materials.

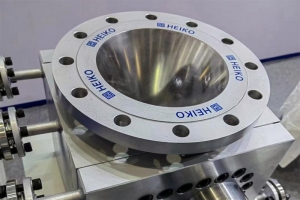

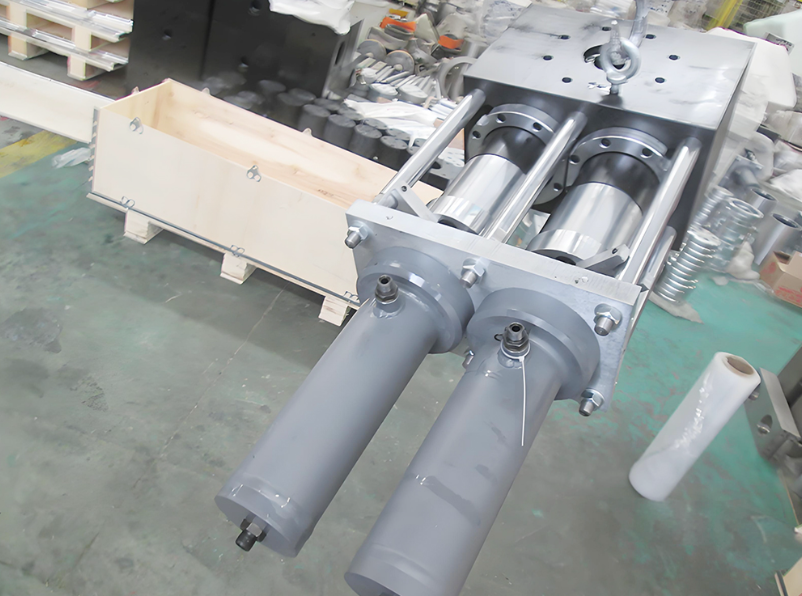

High Pressure Resistance + Contaminant Scouring Resistance: Main body forged from solid 45# steel with nitriding treatment, withstands working pressures up to 35MPa and temperatures ≤350°C, accommodating the high viscosity and high impurity characteristics of recycled material melts. Optimized flow channel design in the screen chamber minimizes melt retention and degradation (recycled materials are prone to degradation at high temperatures).

Hydraulic Drive, Stable and Reliable: Features an integrated hydraulic system with adjustable pressure (0-35MPa). Dual-column guidance ensures positioning accuracy ≤0.02mm, preventing jamming during screen changes. Equipped with pressure sensors for real-time melt pressure monitoring, triggering automatic alarms or screen changes during overpressure conditions.

High filter adaptability: Supports 20-120 mesh metal screens (commonly 40-80 mesh for recycled material filtration). Quick-release filter seat design enables rapid replacement. Single-layer or multi-layer screen combinations can be selected based on impurity levels, allowing flexible adjustment of filtration precision.

Environmentally friendly and energy-efficient, reducing waste: No melt leakage during screen changes prevents recycled material waste. Smooth flow channels eliminate dead spots, reducing melt flow resistance and lowering extruder energy consumption (5%-8% energy savings compared to conventional screen changers).

Selection Guidelines

Match bore diameter to extruder screw diameter (e.g., DN65 screen changer for φ65 extruder);

Select mesh count and pressure trigger value based on recycled material impurity levels (set lower pressure thresholds for higher impurities);

Confirm production temperature (e.g., PA recycled material requires ≥300°C resistance) and melt viscosity to choose corresponding temperature-rated seals (fluororubber / graphite seals).