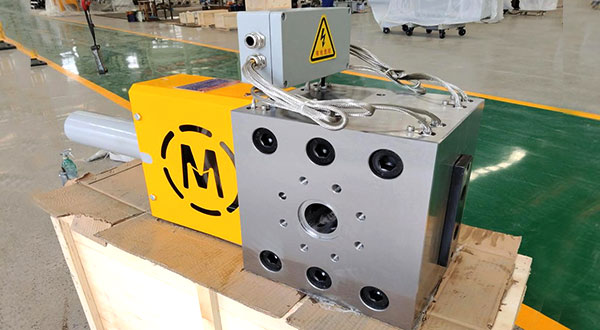

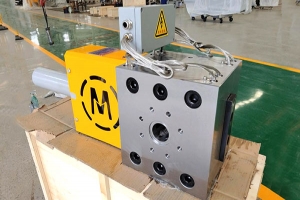

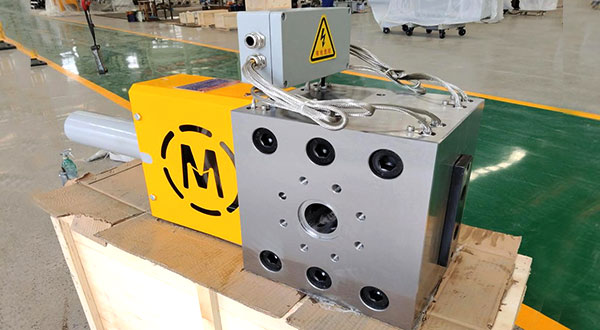

The core of the PVC regranulation plate screen changer (commonly known as a plate changer) features a single-plate, dual-station hydraulic drive system. Its straight-through flow path minimizes retention and enables rapid screen changes. Designed to accommodate the heat-sensitive nature and high impurity content of PVC regranulation material, it is suitable for extrusion pelletizing, profile extrusion, and pipe extrusion applications.

Core Principle and Structure

Working Principle: Hydraulically driven sliding plates enable dual-station screens to alternately engage the flow channel. Screen change time ≤ 2 seconds with minimal pressure fluctuation, allowing non-stop operation to reduce PVC degradation risks.

Core Components: Body (straight-through flow path, no dead zones) Slide plate (dual-station screen mounting position) Hydraulic system (drive and seal compensation) Heating/temperature control unit (160–200°C compatible) Sealing structure (compensated/pressure-activated, leak-proof and pressure-resistant).

Key Selection Parameters

Process Compatibility

Melt Parameters: Temperature 160–200°C, operating pressure ≤30MPa, pressure differential ≤20MPa.

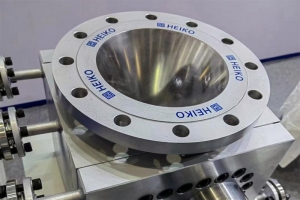

Filter Specifications: 80–120 mesh (combination coarse + fine filtration), filter area matched to output (φ70–φ350mm).

Structure Selection

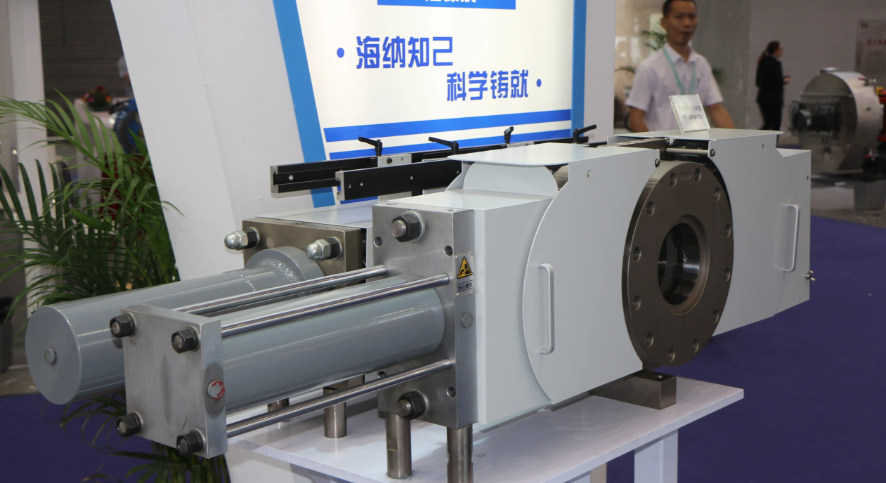

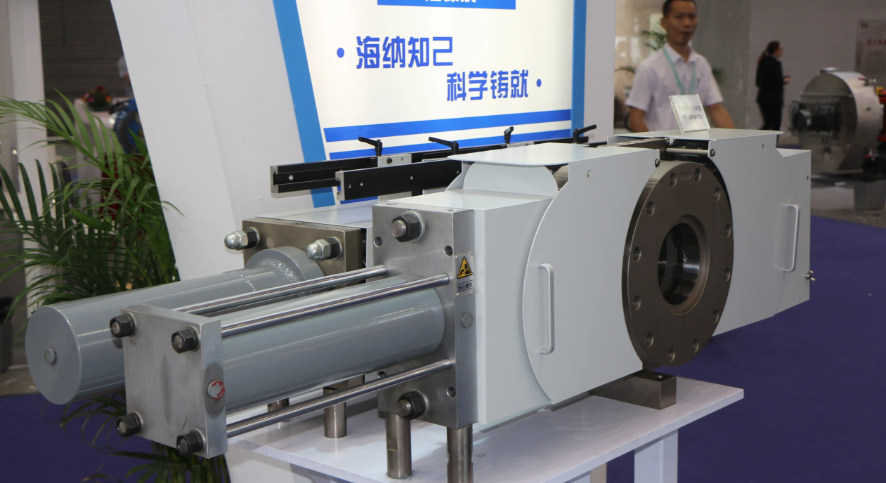

Prioritize single-plate dual-station hydraulic models (high cost-effectiveness, easy maintenance); for high output, opt for dual-plate quad-station models for more stable continuous filtration.

Flow Path: Straight-through design, avoiding right angles/dead corners to minimize residue buildup.

Installation & Interfaces

Flange connections matching extruder/mold diameters; reserved heating and hydraulic interfaces for integrated control.

Application Scenarios & Recommended Pairings

Suitable for: PVC regrind pelletizing, profile/pipe extrusion, sheet production, especially for small-to-medium production lines (≤1000kg/h).

Recommended Pairing: Use with a melt pump to stabilize pressure and flow, enhancing product uniformity and surface quality.