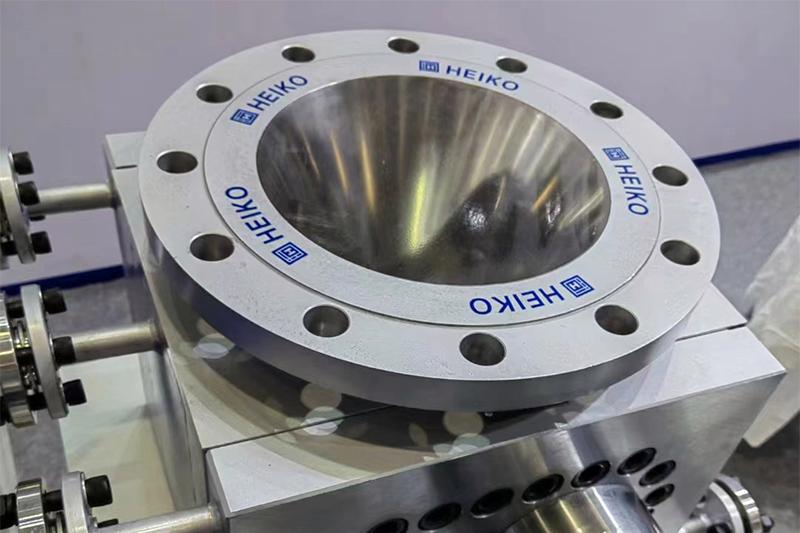

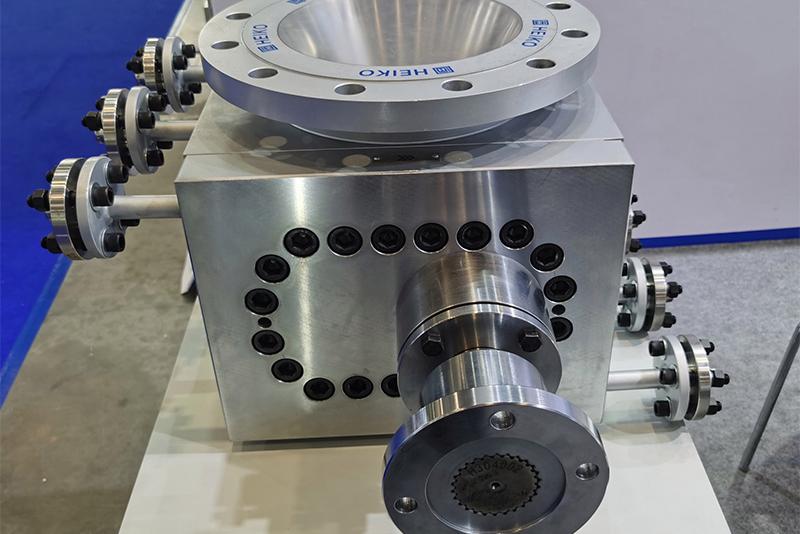

In the production of resins, synthetic fibers, and other polymeric materials, the melt discharge process at the reactor bottom demands exceptionally high equipment compatibility — — It must handle high-temperature, high-viscosity materials while meeting process requirements like vacuum operation and continuous discharge. As a specialized variant of gear pumps, the reactor melt discharge pump precisely addresses these challenges, becoming an indispensable core component in the production processes of PET polyester, nylon, and similar products.

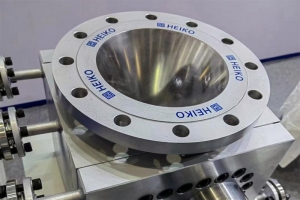

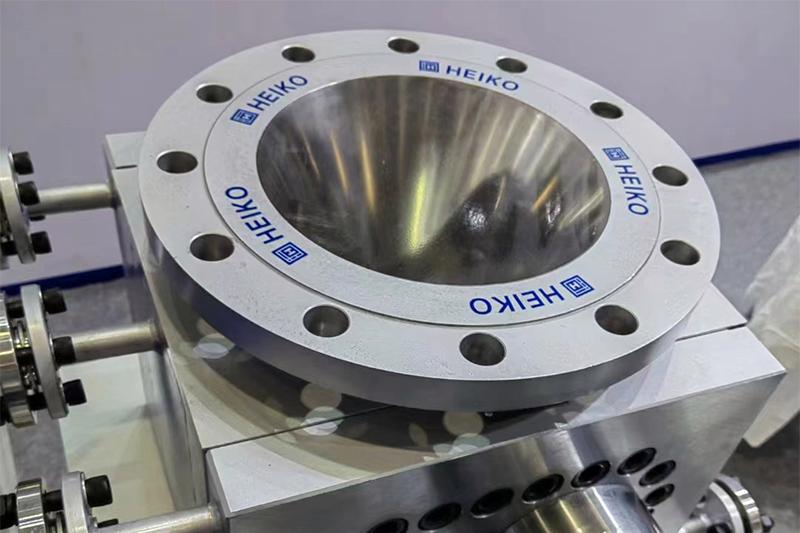

Its core value lies in “precision adaptation to reactor discharge scenarios”: Unlike general-purpose gear pumps, its structure is specifically engineered for reactor bottoms, effortlessly extracting high-temperature, high-viscosity melt deposits. In PET polyester production, for instance, reactor melt temperatures often reach 270-290°C with viscosities exceeding 10,000 cP. whereas ordinary pumps often suffer from “incomplete extraction” or “material residue.” Through optimized suction chamber angles and gear tooth profiles, this pump achieves over 99% extraction efficiency of bottom-residual material. This not only prevents raw material waste but also ensures stable feedstock supply for subsequent processes.

Four core advantages directly address critical polymer production requirements:

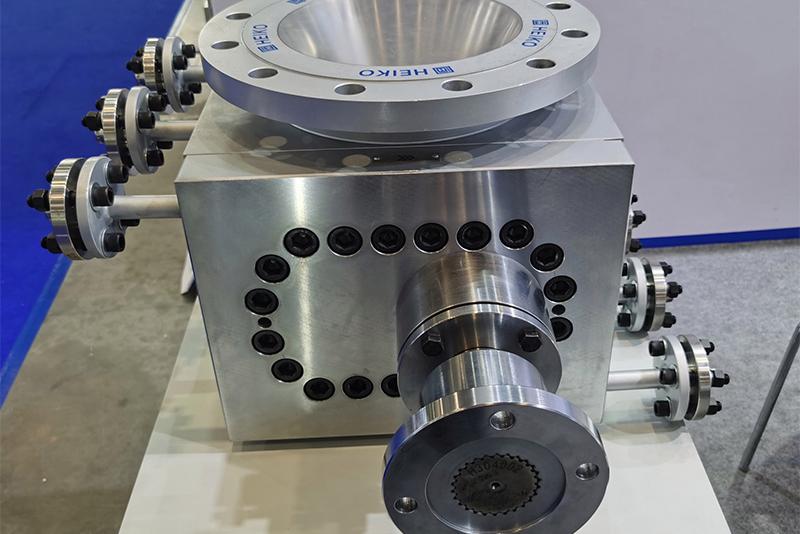

First, high-temperature, high-viscosity material handling capability. Constructed from heat-resistant alloy materials with gear clearance precisely controlled at 5-8μm, the pump withstands temperatures exceeding 300°C while minimizing leakage of high-viscosity melts. Even when conveying glass-filled modified resins, its wear-resistant gear surfaces extend equipment lifespan.

Second, vacuum discharge and oxidation prevention. For vacuum polymerization processes (such as polycondensation in nylon 66 production), the pump delivers outstanding self-priming performance, enabling stable discharge under -0.095 MPa vacuum without additional pressurization. This feature prevents air ingress into the reaction system, avoiding material oxidation and yellowing, thereby directly enhancing product color and mechanical properties.

Third, precise and controllable flow rate. Building upon the core principle of gear pumps—the linear relationship between rotational speed and flow rate—the servo motor controls speed to achieve a flow adjustment range of 0.1–100 m³/h with an error tolerance of ±0.5%. In chemical fiber spinning production, minor speed adjustments precisely match the feed requirements of the spinneret, preventing uneven filament thickness caused by flow fluctuations.

Fourth, continuous stable operation without pulsation. Thanks to precision gear machining, pressure pulsation during pump operation is ≤0.2MPa, and flow pulsation is ≤1%, far below the fluctuation range of traditional discharge pumps.

From “precise material extraction” at the reactor bottom to “stable material supply” in downstream processes, reactor melt discharge pumps address three core challenges in polymer production—difficult discharge, precise material control, and oxidation prevention—through targeted structural design and performance optimization. They serve as the “bridge equipment” connecting reactors to subsequent processing stages, providing critical assurance for the quality stability and production efficiency of resin and chemical fiber products.