The screen changer for plastic filament extrusion machines serves as the core equipment for melt purification and process stability assurance within filament extrusion production lines. Primarily designed to filter contaminants such as impurities, gels, and unmelted particles from the plastic melt, it simultaneously minimizes production interruptions. This component is crucial for enhancing the surface finish, dimensional accuracy, and mechanical properties of plastic filaments.

Common Types and Suitable Applications

Based on process requirements for plastic filament extrusion (e.g., melt viscosity, extrusion speed, filament precision), mainstream screen changer types and their characteristics are as follows:

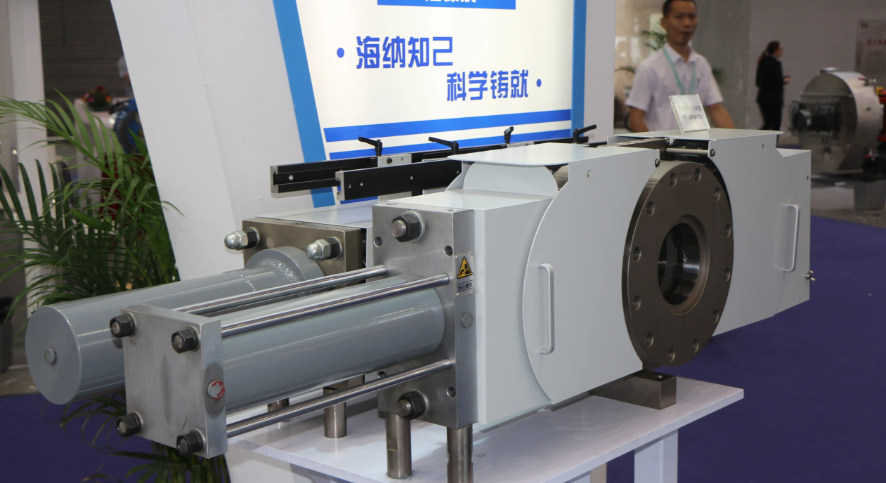

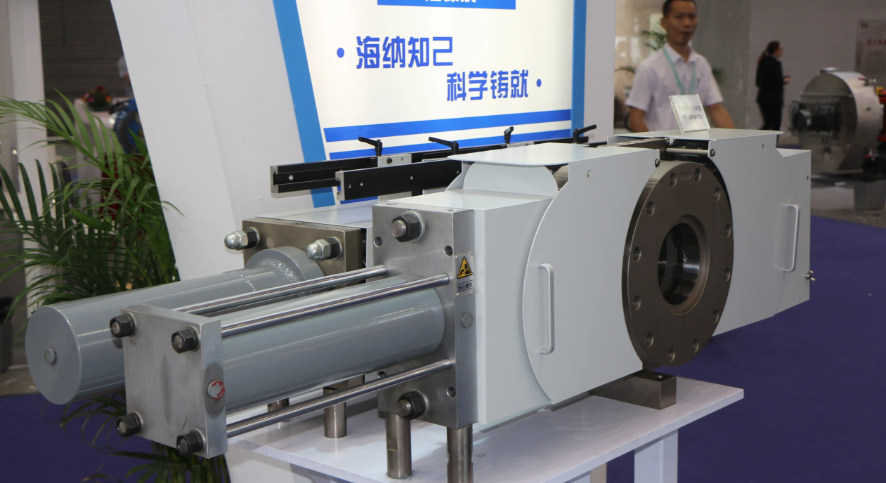

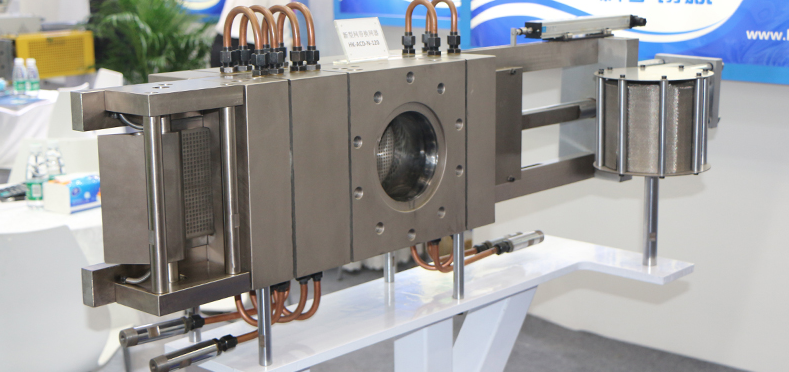

double column hydraulic Screen Changer (Recommended Mainstream Type)

Structural Features: Utilizes two parallel working chambers—one active, one standby—with hydraulic/pneumatic/electric drive switching to enable online screen changes without production stoppage.

Suitable Applications: Ideal for medium-to-high capacity filament production lines (e.g., PP/PE braided filaments, PA fishing lines), recycled material filament extrusion (high impurity content requiring frequent screen changes), and modified filament extrusion (e.g., glass-fiber reinforced PA filaments). Particularly suited for large-scale production demanding high continuity.

Core Advantages: Smooth screen changes with minimal pressure fluctuations ensure consistent filament dimensional stability. Maintenance is simplified, allowing simultaneous cleaning/replacement of filter components during production.

Single column Extrusion Screen Changer

Structural Features: Single-chamber design requires shutdown and filter component disassembly during screen changes. Features a simple structure and lower cost.

Suitable Applications: Low-capacity, low-precision filament production (e.g., standard baling wire), laboratory-scale extruders, or simple extrusion of virgin material with minimal impurities.

Limitations: Downtime for screen changes reduces efficiency and causes material waste; unsuitable for high-precision filament production.

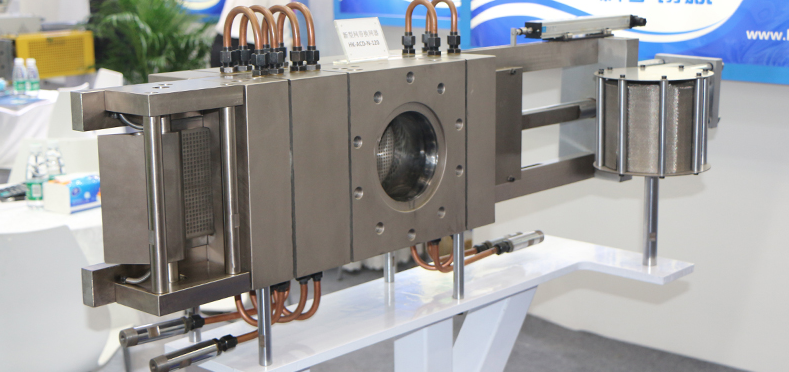

Single Plate Screen Changer

Structural Features: Screen changes are achieved by sliding filter plates, which can be designed with multiple filter stations for rapid switching.

Suitable Applications: Medium-to-low pressure, medium-viscosity plastic filaments (e.g., PVC electrical wires, PE tubing filaments), particularly suited for space-constrained production lines (compact design).

Considerations: Sealing performance significantly impacts pressure stability; high-temperature and wear-resistant sealing materials must be selected.

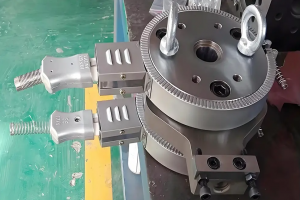

Self-Cleaning Screen Changer

Structural Features: Automatically cleans impurities via built-in scrapers or rotating filter elements, eliminating frequent disassembly of filter assemblies.

Suitable Applications: Ideal for high-impurity environments requiring continuous operation (e.g., large-scale recycled plastic filament production), reducing manual maintenance frequency.

Limitations: Relatively limited filtration precision; unsuitable for high-purity precision filaments (e.g., 3D printing filaments).

Common Troubleshooting

Filament Impurity Defects: May indicate damaged screens or insufficient mesh count. Replace with qualified screens; add pre-coarse filtration if necessary.

Filament Breakage During Screen Change: Often caused by slow change speed or excessive pressure fluctuations. Optimize drive parameters (e.g., increase hydraulic switching speed) or select a screen changer with smoother flow transition.

Melt leakage: Typically caused by aged or improperly installed seals. Replace seals and tighten according to specifications. Simultaneously inspect for deformation in the cylinder or plate assembly.