The plastic filament extrusion metering pump is the core equipment ensuring process stability and product quality in filament extrusion. Through high-precision metering, stable pressure output, and rapid response adjustments, it significantly enhances filament uniformity, reduces defect rates, and adapts to diverse production requirements.

Core Function Analysis

High-Precision Metering

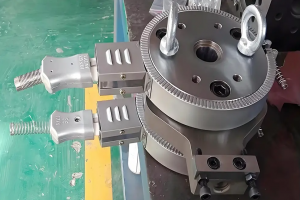

Operating on a positive displacement mechanism, the metering pump achieves high-precision melt delivery through gear meshing. Its displacement strictly correlates with gear rotation speed, delivering flow accuracy within ±1%. For instance, when producing fine-diameter fibers requiring flow fluctuations controlled within ±0.5%, the metering pump maintains this precision to ensure uniform filament diameter.

Stable Pressure Output

The metering pump delivers constant pressure to the melt, preventing filament breakage or diameter inconsistencies caused by pressure fluctuations. Outlet pressure is precisely controlled by adjusting rotational speed or back-pressure valves. With a pressure rating up to 350 kg and a temperature range covering high-temperature melts below 500°C, it accommodates diverse process requirements.

Rapid Response Adjustment

When drawing process parameters (e.g., temperature, speed) change, the metering pump swiftly adjusts pressure and flow to maintain production stability. For instance, during wire gauge changes, its dynamic regulation capability minimizes downtime and enhances production efficiency.

Application Scenarios and Selection Criteria

Typical Applications

Plastic Filament Extrusion: Produces fibers, monofilaments, and multifilaments from materials like PVC, PP, and PE, meeting demands for high-end fibers, films, pipes, and other products.

Key Selection Parameters

Flow Rate Range: Select appropriate displacement based on production needs. For melt-spun filaments, metering pumps with flow rates of 0.3–3 cm³/r are commonly used.

Pressure Rating: Select pressure-resistant grades based on melt viscosity and process requirements to ensure stable pump operation under high pressure.

Material Compatibility: Choose pump body materials according to melt chemical properties, such as corrosion-resistant stainless steel or special alloys, to prevent medium corrosion.

Viscosity Range: Opt for pump types suitable for wide viscosity ranges, e.g., handling melts from 100 Pa·s to 10,000 Pa·s.