The manual screen changer for blown film production is a device designed for high-viscosity melt extrusion lines such as blown film applications. Featuring a dual-station design for manual screen switching, it offers simple construction, flexible operation, and low cost. However, it requires machine shutdown for screen changes and is suitable for scenarios with less stringent requirements for continuous production.

I. Structure and Working Principle

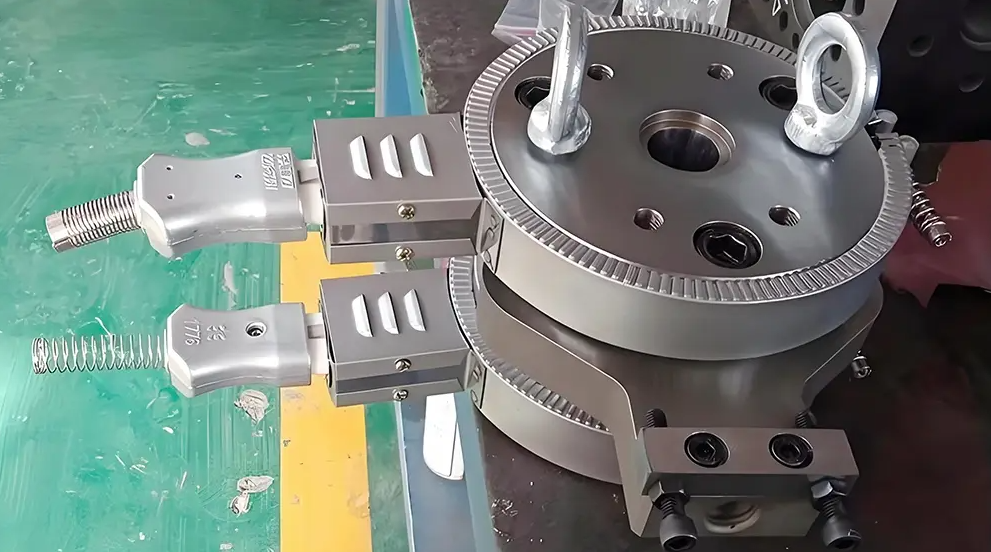

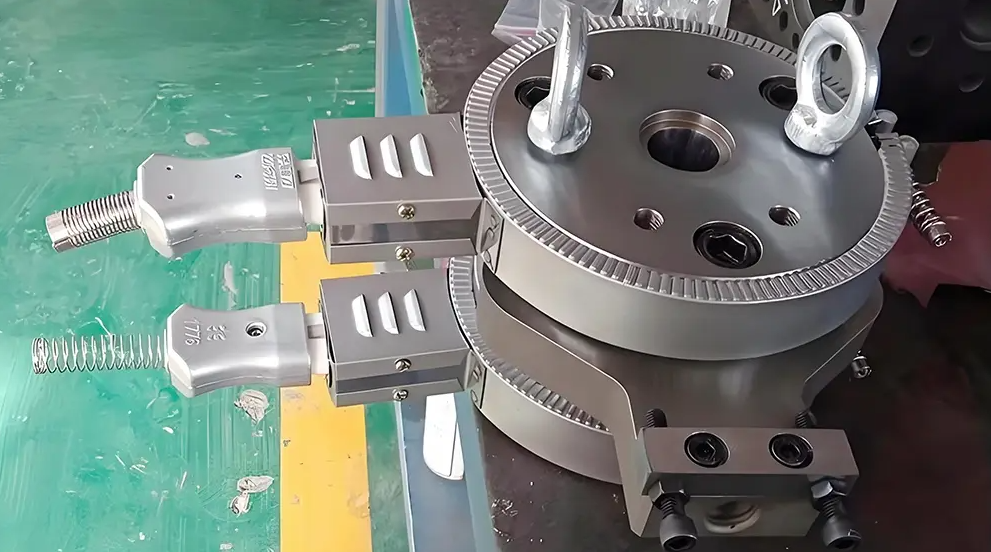

Dual-Station Design

The manual screen changer typically features two filter stations: one active and one standby. When the active screen accumulates impurities causing pressure buildup or compromising product quality, operators manually switch to the standby screen.

Manual Switching Mechanism

Switching must occur during deceleration or shutdown. Operators manually pull the contaminated screen out of the housing using a handle or lever while simultaneously pushing the clean spare screen into position. This “magazine-style” process requires precise alignment to prevent melt leakage.

Sealing and Flow Path Design

Unique flexible or rigid sealing devices prevent leakage of high-temperature, high-pressure melt. Internal flow paths are mirror-polished to minimize melt retention and degradation risks. Some models incorporate positioning blocks and bolts for enhanced accuracy during filter changes.

II. Core Advantages

Low Cost, Simple Structure

Compared to hydraulic or fully automatic screen changers, manual units eliminate complex hydraulic systems or electrical controls, significantly reducing equipment costs. Their compact design minimizes space requirements, making them ideal for small production lines or budget-constrained enterprises.

Flexible Operation and Adaptability

Compatible with extruders of various standards, suitable for high-viscosity melt extrusion applications including blown film, cast film, and drip irrigation tape. The operating lever position can be adjusted according to production site space, enhancing operational convenience.

Stable Filtration Performance

By pre-installing filters of different mesh sizes (e.g., 80-300 mesh), impurities, unplasticized particles, and decomposition residues in the melt can be effectively intercepted, improving product surface quality and mechanical properties. For instance, when producing transparent film, selecting high-precision filters ensures film clarity.

Application Scenarios & Selection Recommendations

Suitable Scenarios

Small-scale film blowing lines with low production continuity requirements.

Enterprises with limited budgets needing to control equipment costs.

Processing raw materials with low impurity content (e.g., virgin material), resulting in low screen change frequency.

Selection Criteria

Mesh Count: Select based on product requirements—transparent films require 200 mesh or higher, while standard packaging films can use 80–150 mesh.

Sealing Performance: Prioritize rigid seal designs with pressure resistance exceeding 30 MPa.

Operational Convenience: Verify adjustable control levers and precise positioning blocks/bolts.