A screen changer is an industrial device used to filter foreign particles and impurities from plasticized materials, widely applied in melt processing fields such as plastics, rubber, and ceramics. Below are its core classifications and functional characteristics:

Manual Screen Changer

Screens are switched manually, offering low cost but requiring shutdown for replacement. Suitable for small-scale production scenarios.

Filter diameter typically under 100mm due to sealing and friction limitations.

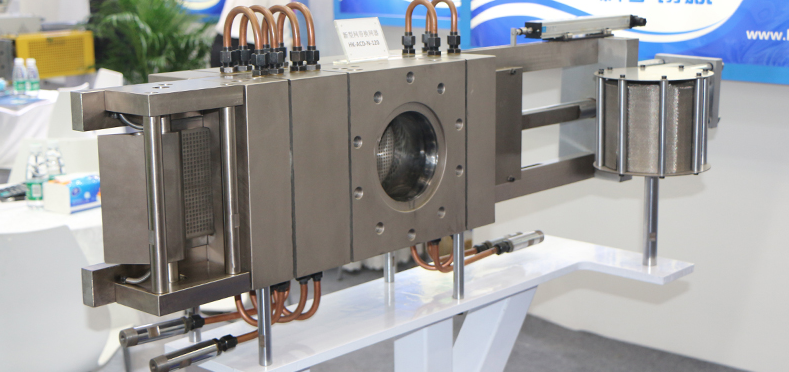

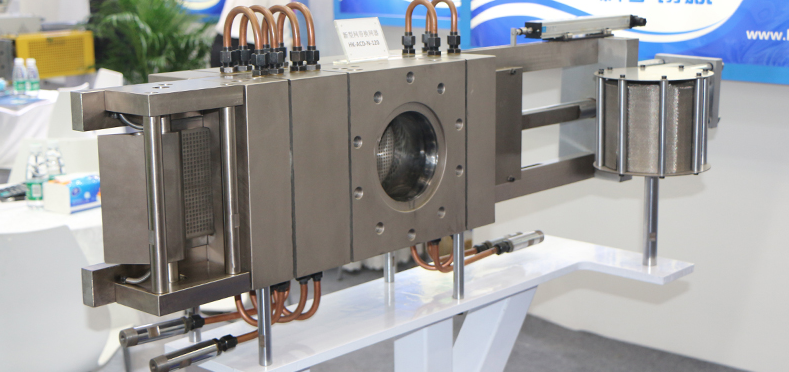

Hydraulic Screen Changer

Utilizes hydraulic drive for screen plate or cylinder replacement, achieving rapid changeover (1-3 seconds) with superior sealing. Suitable for high-viscosity materials (e.g., PE, PP, PVC).

Operates at pressures up to 40MPa and temperatures up to 300°C, compatible with pelletizing, film blowing, and other production lines.

Mesh belt Fully Automatic Screen Changer

Enables fully automated operation without manual intervention, suitable for long-process products like film and optical fiber.

Maintains stable pressure during screen changes, ensuring consistent material flow and suitability for pressure-sensitive processes.

II. Core Functions of Screen Changers

Impurity Filtration: Removes decomposition products and foreign particles from the melt to ensure continuous production.

Rapid Switching: Hydraulic quick-change screen changers complete filter replacement within 1-3 seconds, minimizing material waste.

High-Temperature/High-Pressure Compatibility: Select models withstand pressures up to 30MPa and temperatures up to 300°C, suitable for extreme operating conditions.

III. Mesh Changer Application Scenarios

Plastic Processing: Pelletizing, film blowing, pipe forming, etc.

Recycled Material Handling: Enhances quality when filtering high-ratio recycled materials.

Industrial Equipment: Compatible with extruders, melt pumps, reactors, etc.