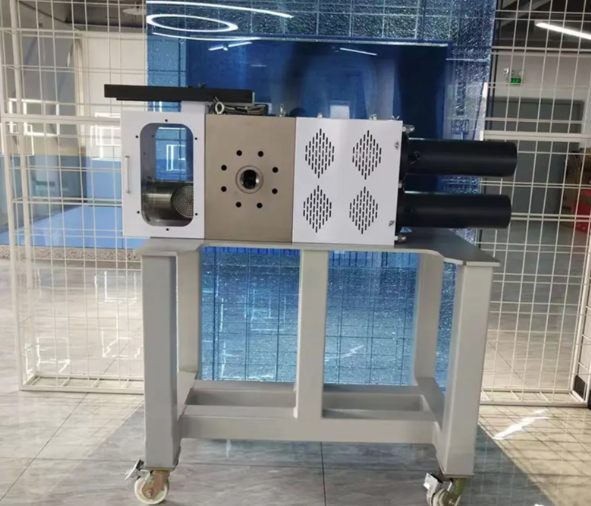

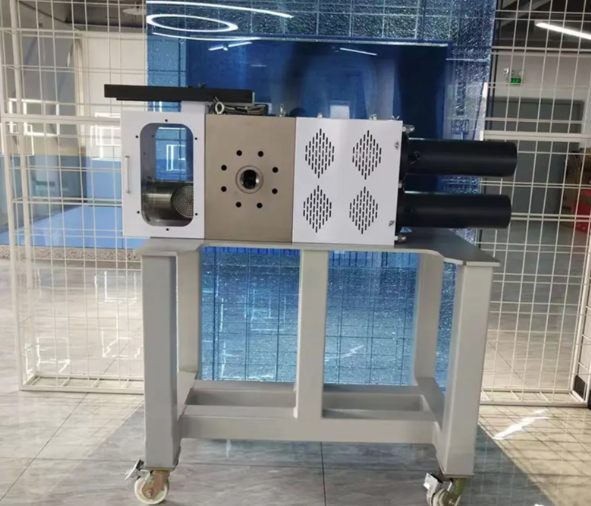

The main features of double column screen changer for twin-screw granulator are as follows:

Structure and Function

Adopting double-channel and double-filter screen structure, one screen works and the other is replaced when changing the screen, realizing screen changing without stopping and ensuring the continuity of production.

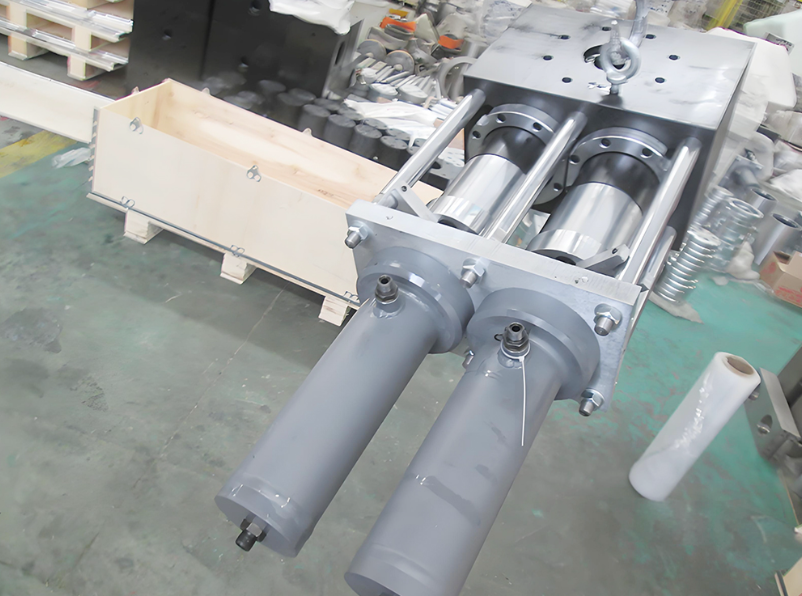

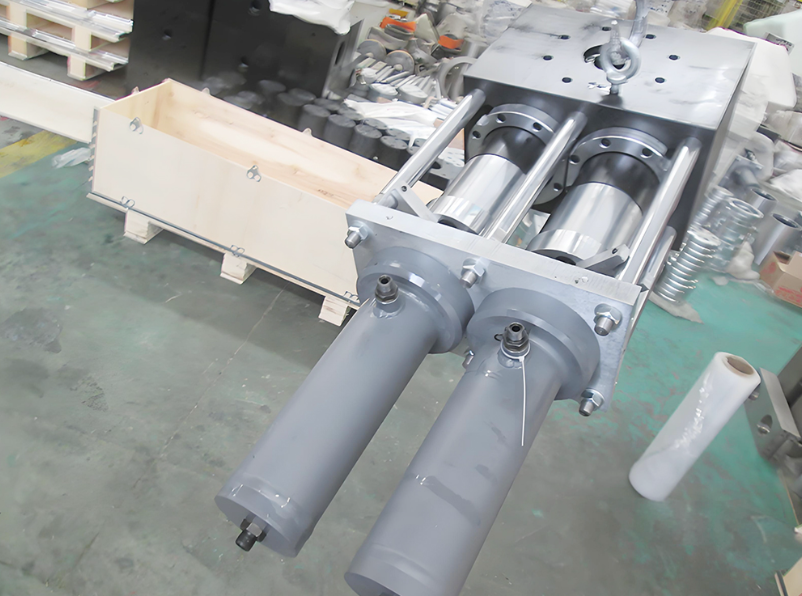

Filtration design

Dual flow channel: increase the filtration area to meet the demand of high output and high quality production. Curved screen: increase the filtration area and improve the efficiency. Rigid sealing: prevent leakage and prolong service life.

Operational features

Hydraulic drive: fast screen switching, the whole process only takes 3-5 seconds. Air Exhaust System: Exhausts gases from the material to avoid product defects. Charging and exhausting: Ensure product continuity during screen changing.

Applicability and safety

Multi-field applicability: suitable for production of chemical fiber, blown film, pipe, plate and so on. Safety Protection: Fully enclosed design to reduce the risk of high temperature melt contact.

Maintenance and Economy

Automation control: reduce the risk of manual operation. Energy saving and environmental protection: Reduce downtime and energy consumption. Screen life: Intelligent pressure control extends screen life.

Double column screen changers are widely used in the following areas:

High-performance engineering plastics

Processing PA66+30% glass fiber, PBT+20% mineral filler and other materials to enhance tensile strength (≥150MPa) and heat distortion temperature (≥200℃).

High filling granulation

Processing wood-plastic composites with 50% wood powder content and magnetic plastics with 70% ferrite filling, keeping the granule compactness ≥1.2g/cm³.

Recycling and Modification

In the waste plastic recycling line, filtering impurities and degradation materials, improving the quality of recycled pellets to meet the requirements of wire drawing, injection molding and other processes.

Special Process Requirements

Integration of melt gear pumps, underwater pelletizing die head and other components to form a complete set of solutions for complex processes such as co-mingling, sol-gel and adhesive type.

Twin Screw Pelletizer Twin column screen changer realizes high efficiency filtration, stable production and low maintenance cost through the design of double screen synergy, hydraulic drive and rigid sealing, which is ideal for high performance plastics processing, high filler pelletizing and recycling modification. When selecting the model, you need to combine the material characteristics, process requirements and budget, and give priority to the products with modular design and perfect automatic control function.