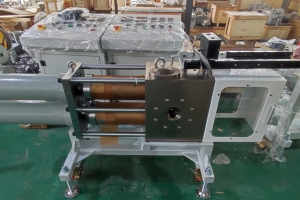

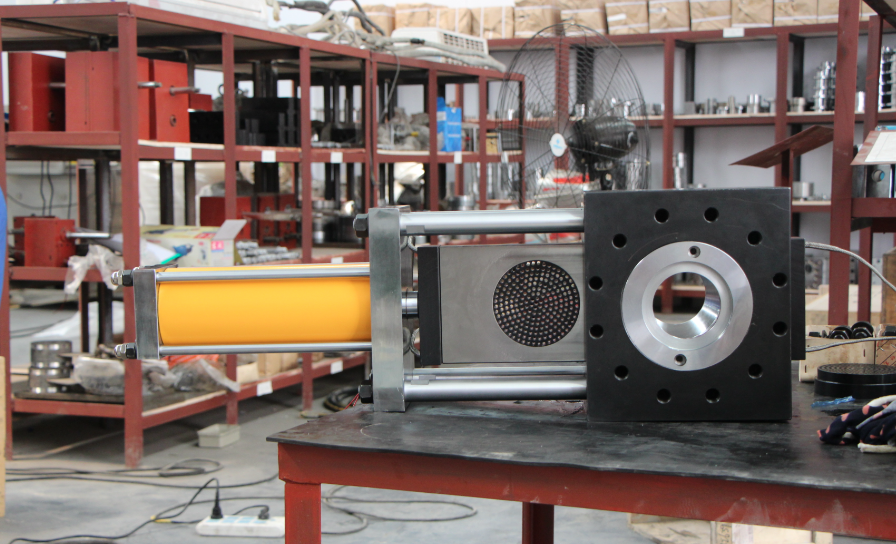

The single-plate screen changer is a critical filtration device widely used in the continuous production processes of polymer materials such as plastics, chemical fibers, and rubber. Its core function is to efficiently filter impurities from the melt, ensuring product quality and production continuity. Below is an analysis of its professional applications and technical features:

Workstation Classification

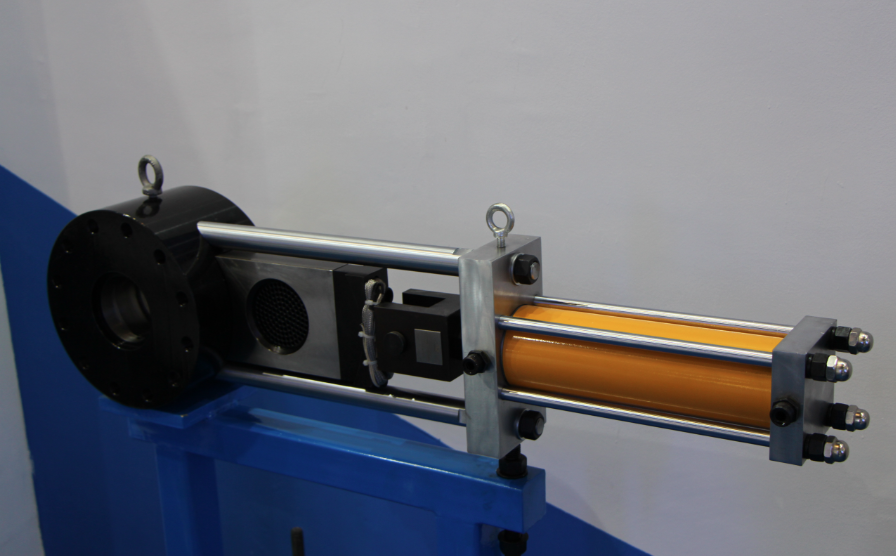

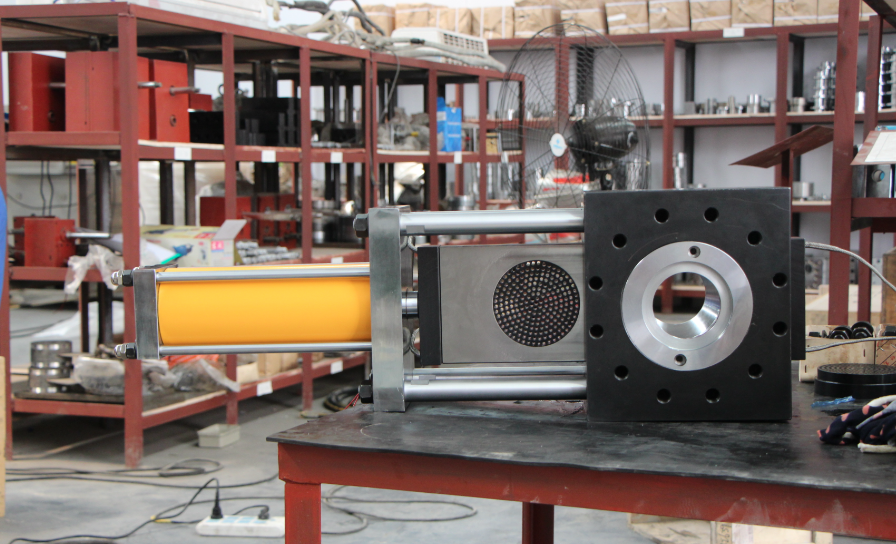

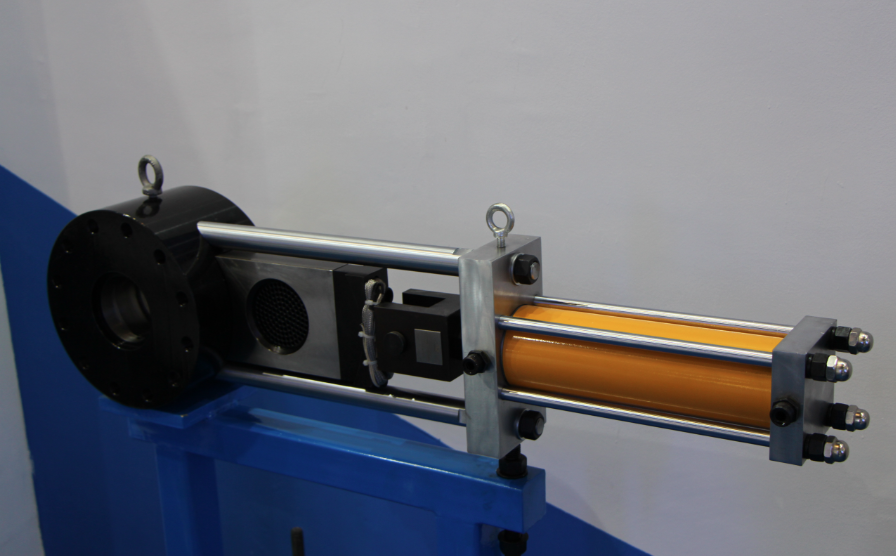

Single-Station Screen Changer: Requires halting production equipment during screen changes, restarting after completion, leading to production interruptions and reduced efficiency. However, it features relatively simple structure and lower cost. Examples include single-plate single-station screen changers and single-column single-station screen changers.

Multi-Station Screen Changers: Includes dual-station or quad-station models. During screen changes, the spare filter enters operational status in advance, enabling non-stop screen changes. This ensures production continuity and enhances efficiency, though the equipment is relatively higher in cost and more complex in structure.

Core Application Fields

Plastic Extrusion Industry: During processing of raw materials like PE, PP, and PVC, these filters intercept contaminants such as carbonized particles and metal shavings, preventing die plate blockages. This significantly enhances the light transmittance and mechanical strength of films and pipes.

Chemical Fiber Spinning: Used in melt spinning of polyester, nylon, etc., with filtration precision reaching 20-150 microns. Prevents discolored fibers and reduces fiber breakage rates (industry data indicates over 30% reduction in downtime).

Recycled Material Processing: Addressing the high impurity content in recycled plastics, it employs a multi-layer sintered metal mesh design to achieve >98% impurity retention, ensuring the purity of recycled pellets.

When selecting a hydraulic screen changer, comprehensive consideration should be given to multiple factors including material properties, product types, production volume, material pressure within the system, and automation level. For further information, consulting a professional is recommended!