The Core Role of Screen Changers in PP Recycled Plastic Filament Extrusion

During PP recycled plastic filament extrusion, raw materials may contain contaminants (such as paper scraps, sand particles, label adhesive, etc.). These impurities can clog molds, cause filament breakage, or compromise flat filament strength. Screen changers ensure process continuity and product quality by filtering contaminants from the melt. Their core functions include:

High-Efficiency Filtration: Intercepts solid particles in the melt to prevent mold clogging.

Continuous Production: Supports non-stop screen changes, minimizing downtime losses (particularly beneficial for recycled materials with high impurity variability).

Extended Equipment Lifespan: Reduces wear on screws and molds caused by impurities, lowering maintenance costs.

II. Technical Selection Criteria for PP Recycled Plastic Filament Drawing Screen Changers

Based on process requirements, screen changers must meet the following technical conditions:

High Temperature & Pressure Resistance: PP melt temperatures typically range from 180-230°C, requiring screen changers with temperature resistance ≥250°C.

Corrosion Resistance: Recycled materials may contain acidic or alkaline impurities; screens and seals must be made of stainless steel (e.g., 316L) or corrosion-resistant alloys.

Filter Precision:

Select mesh count (e.g., 80-200 mesh) based on flat filament specifications. Double-layer screens (coarse-to-fine filtration) are recommended for recycled materials.

Screen Change Methods:

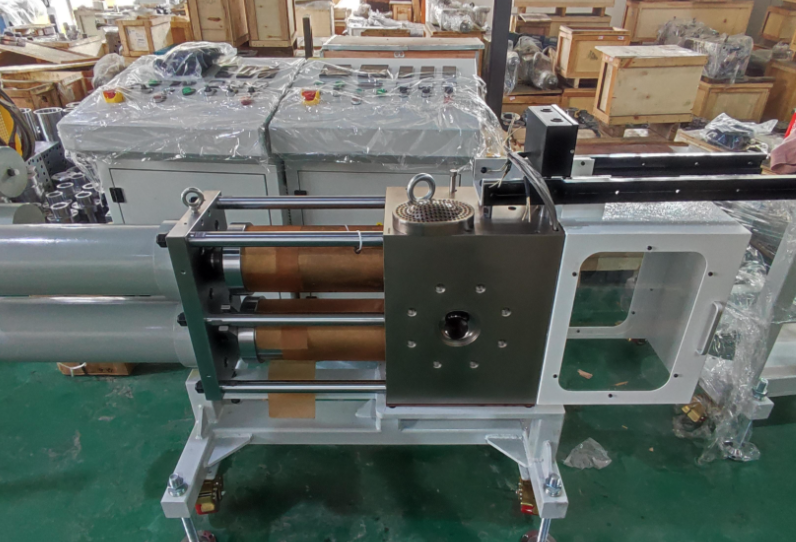

Hydraulic Automatic Screen Changer:

Suitable for continuous production, with change time ≤3 seconds and pressure fluctuation<5%.

Manual Screen Changer:

Suitable for small-scale or intermittent production, offering lower cost but requiring machine shutdown for operation.

III. Typical Application Cases and Performance Comparison

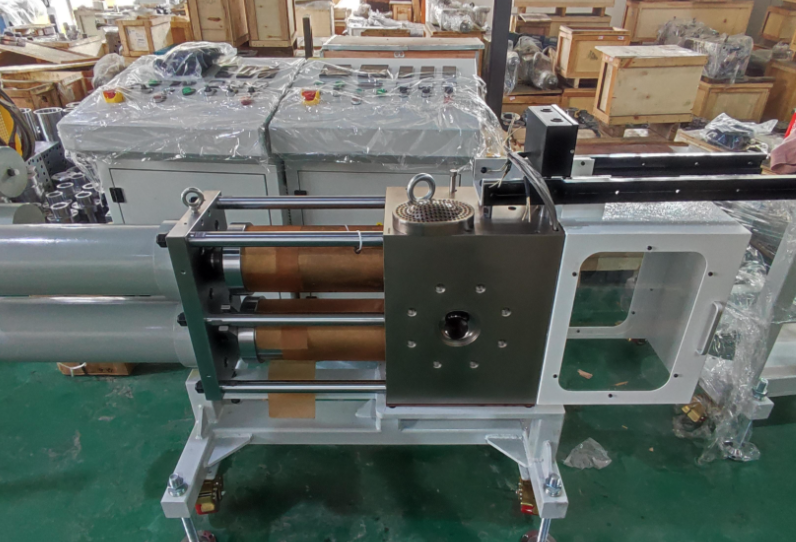

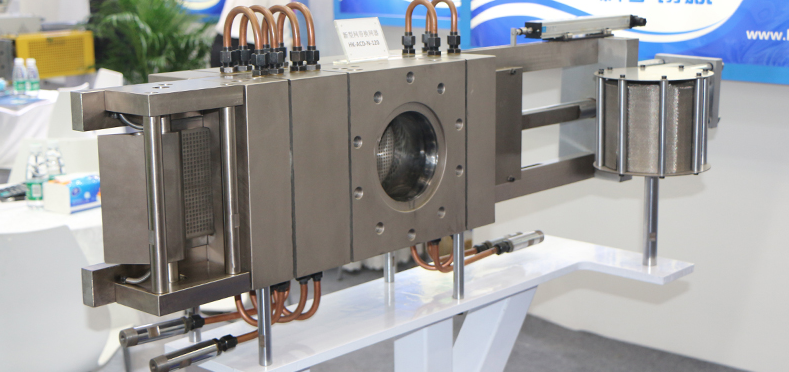

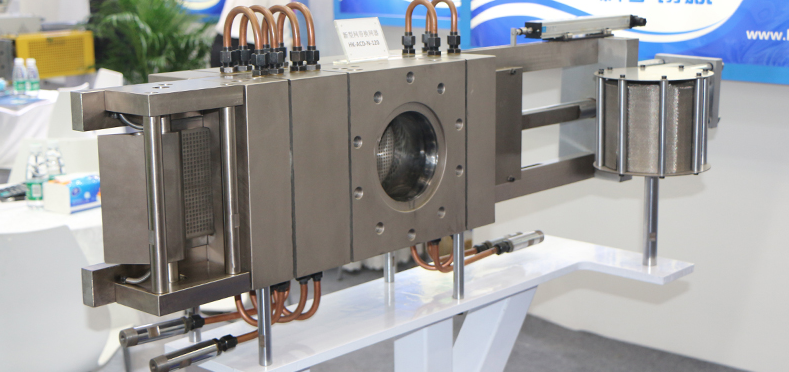

Taking the HK-ACB screen changer from Zhengzhou Haike Melt Pump Co., Ltd. as an example:

| Parameter | HK-ACB Screen Changer | Industry Average |

|---|

| Applicable Materials | PET, PC, PP, etc. | General-purpose (PP adaptability requires verification) |

| Filtering Area | Dual-station design, enabling continuous operation | Single-station design, requiring shutdown for screen changes |

| Pressure Resistance | 25-30 MPa | 15-20 MPa |

| Temperature Resistance Range | ≤300℃ | ≤250℃ |

| Screen Change Time | Hydraulically driven, ≤3 seconds | Manually operated, ≥2 minutes |

| Sealing Performance | Dynamic sealing technology, with a material leakage rate of <0.1% | Traditional sealing, with a material leakage rate of >0.5% |

Advantages:

Dual-station design: While one station operates, the other preheats the new filter screen, enabling seamless switching.

Exhaust structure: Completely purges gas before screen changes to prevent bubbles causing fiber breakage.

Filter screen preheating: Ensures the new filter screen matches the temperature of the online filter, preventing melt crystallization.

The selection of PP recycled plastic filament screen changers should be based on production scale, raw material quality, and budget. Hydraulic automatic screen changers (such as the HK-ACB model) are the preferred choice for continuous production scenarios. Their dual-station design, venting, and preheating functions significantly enhance production efficiency and product quality. For small-scale or intermittent production, manual screen changers can serve as a transitional solution, but strict adherence to operating procedures is essential to prevent material leakage or filament breakage.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447