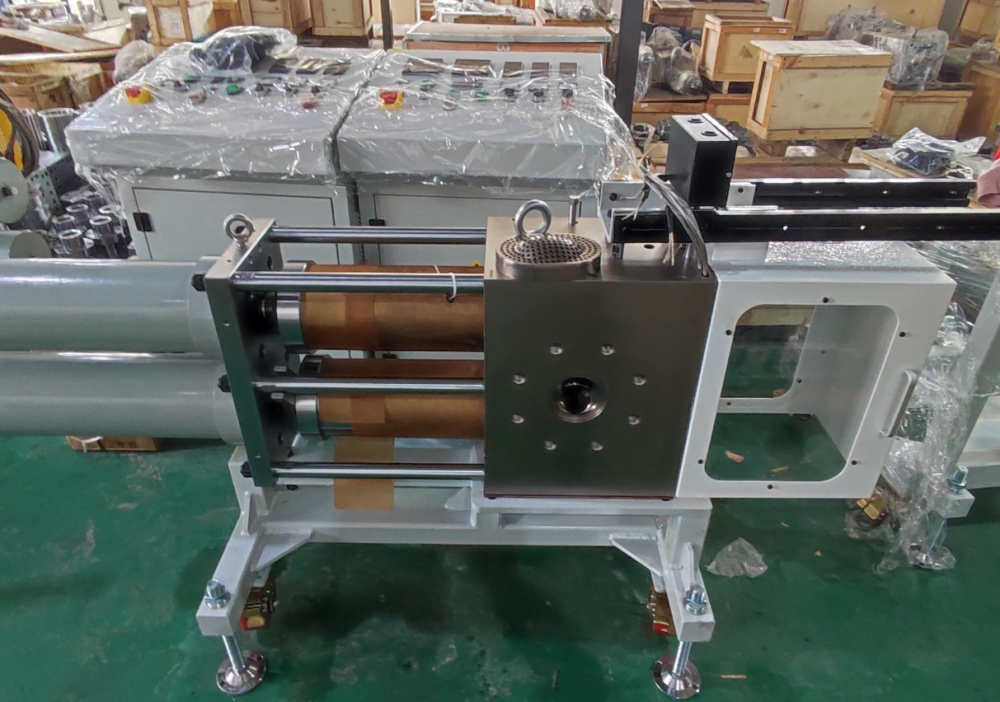

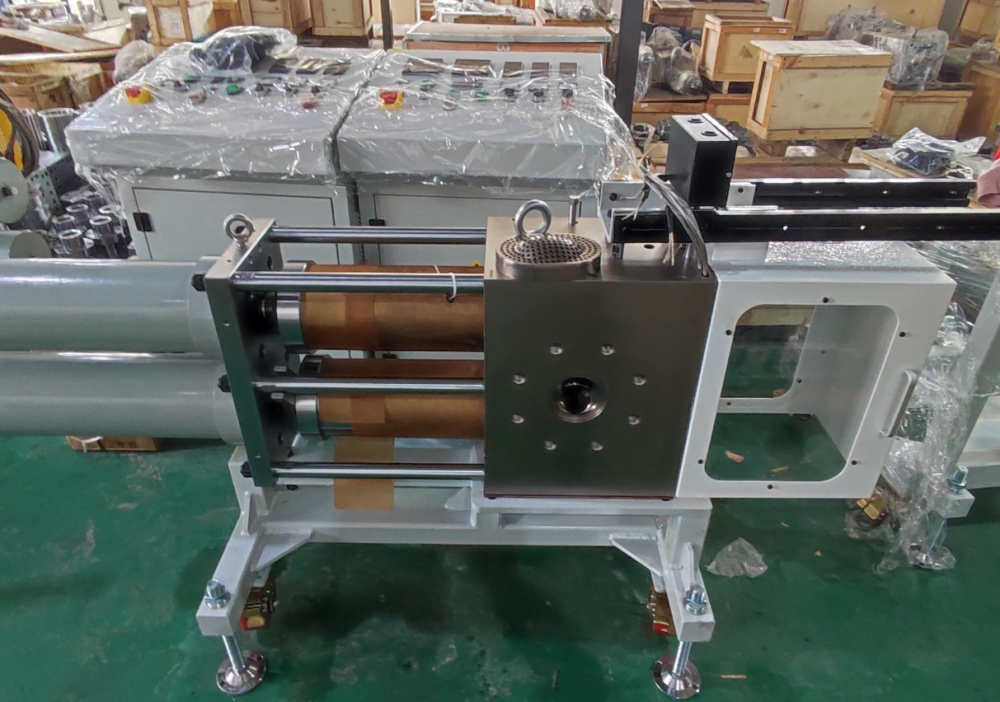

Screen changers play a crucial role in plastic film extrusion production lines, with their core functions and advantages summarized as follows:

I. Core Function Analysis

High-Efficiency Impurity Filtration

Filtration Targets: Precisely intercepts aging particles, metal debris, gel particles, non-plastic substances (e.g., paper/wood shavings), and incompatible plastics (e.g., recycled materials with differing melt indices) within the plastic melt.

Application Scenarios: In film sheet production, 100-300 mesh screens intercept crystalline spots, significantly enhancing film light transmission while reducing surface defects like blemishes, bubbles, and holes. For example, in PVC film manufacturing, screen changers filter metal contaminants like copper and aluminum shavings to prevent inner wall scratches.

Improved Melt Uniformity

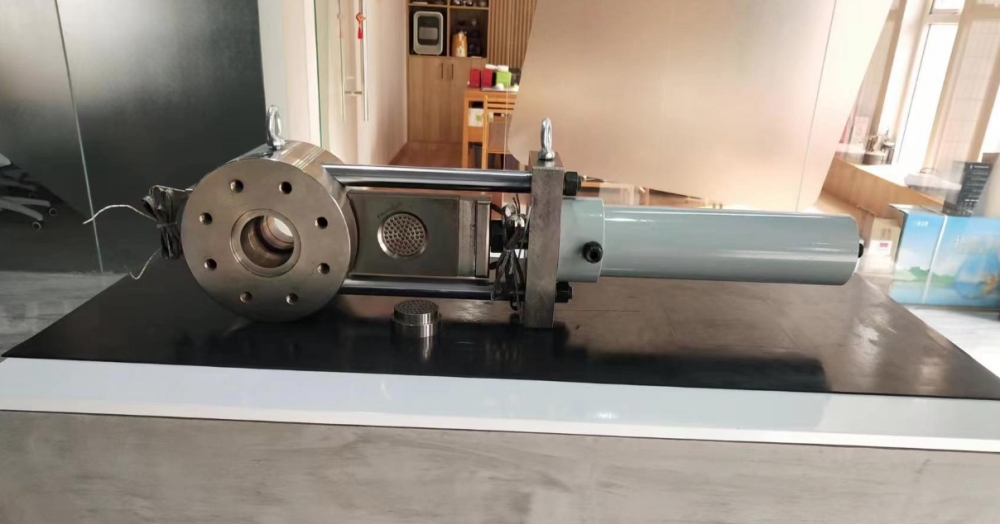

Optimized Rheological Behavior: The screen changer transitions melt flow from rotational to linear motion. Combined with the “damping” effect of the porous plate and filter mesh, it ensures consistent melt velocity across the cross-section, preventing “polymer orientation” and laminar flow phenomena.

Enhanced Physical Properties: Increases longitudinal strength while reducing transverse strength, resulting in more balanced overall tear resistance. For example, in PE gas pipe production, the screen changer ensures uniform wall thickness, improving pressure resistance by 15%-20%.

Protect Equipment and Molds

Extended Lifespan: Contaminants entering the screw, barrel, or mold accelerate wear, increasing equipment maintenance costs by 30%-50%. By intercepting impurities, the screen changer extends mold service life by 1-2 years.

Reduced Downtime: Prevents unplanned shutdowns caused by mold jamming due to contaminants, reducing annual downtime by over 50 hours.

II. Application Areas and Selection Recommendations

Typical Application Scenarios

Film & Sheet Production: BOPP, BOPET, CPP film manufacturing. Filter mesh count: 200-400 mesh to ensure crystal-free surfaces.

Pipe & Profile Extrusion: PVC water pipes, PE gas pipes. Filters metal debris to maintain inner wall smoothness ≤0.02mm.

Cable Compound Pelletizing: Utilizes dual-station screen changers to filter copper/aluminum shavings, supporting high-speed extrusion (line speed ≥500m/min).

Recycled Plastic Processing: Requires high-filtration-area screen changers for handling recycled materials with ≥5% impurity content.

Key Selection Factors

Material Properties: High-viscosity materials (e.g., PA, PC) necessitate screen changers with short flow paths and low pressure drop.

Production Speed: High-speed lines (e.g., cast film) require hydraulic screen changers with response times ≤1 second.

Sanitation Requirements: Food-grade film production mandates sanitary-grade materials to prevent secondary contamination.

Screen changers are core equipment in plastic film extrusion lines, where their filtering, homogenizing, and protective functions directly determine product quality and production efficiency. Through optimized selection (e.g., dual-station, high-precision screens) and technological upgrades (e.g., hydraulic drive, in-line screen change), enterprises can achieve cost reduction and efficiency gains while enhancing market competitiveness. In emerging fields like recycled plastic recovery and high-speed extrusion, the technological value of screen changers will become increasingly prominent.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447