Design Features: Suitable for high-filler, high-wear applications

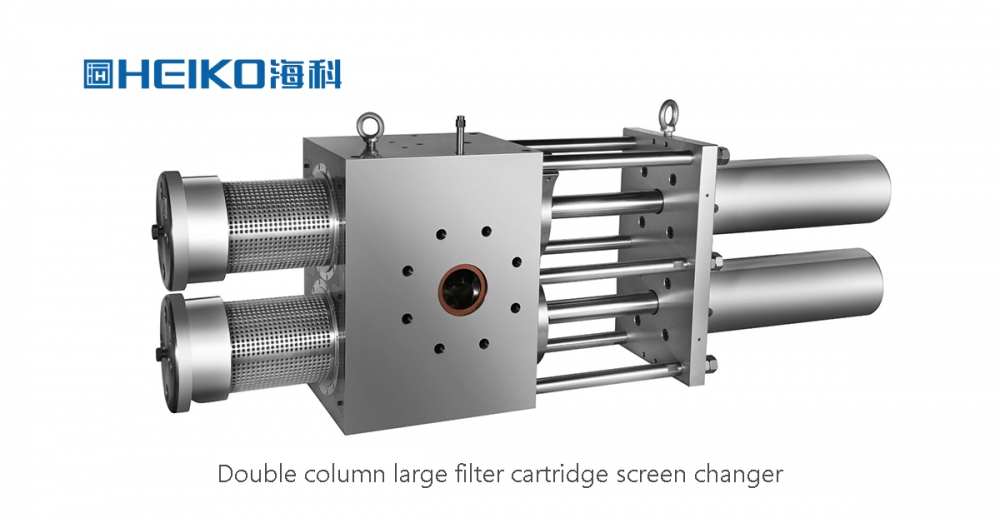

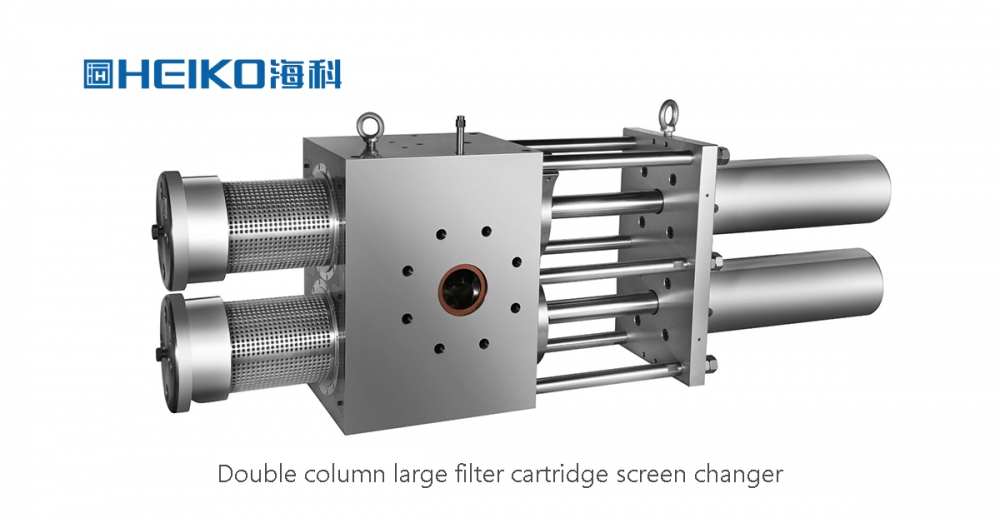

Dual-Column Four-Station Structure

Some high-end models feature a four-channel four-station design, with four screens operating simultaneously, resulting in a filtration area over 50% larger than traditional dual-station screen changers. For example, in high-filler granulation of HDPE + 40% ceramic powder, the four-station screen changer can extend filter screen lifespan to 8 hours (compared to 4-5 hours for traditional dual-station models), reducing filter screen replacement frequency and production costs.

Wear-resistant materials and flow channel optimization

Material selection: The screen changer body and screens are made of high-corrosion-resistant alloy steel (e.g., Hastelloy C-276), with a hardness of HRC ≥ 55, offering wear resistance 3-5 times that of ordinary carbon steel, capable of withstanding continuous erosion by ceramic powder.

Flow channel design: The flow channel angle is precisely calculated (typically 120°-150°), reducing melt residence time and preventing ceramic powder sedimentation and blockage. For example, in the production of masterbatch with HDPE + 15% ceramic powder, optimized flow channel design can reduce the pressure drop of the screen changer by 15% and ensure more uniform melt flow.

Automated control and integrated functions

The dual-column screen changer can be integrated with a PLC control system to automatically monitor and alarm for screen change pressure, temperature, and time. For example, when screen blockage causes the pressure differential to exceed the set value (e.g., 15 MPa), the system automatically initiates the screen change procedure without manual intervention. Additionally, certain models can be connected to melt gear pumps, underwater pelletizing die heads, and other equipment to form a complete pelletizing solution, improving production efficiency by over 20%.

Selection Recommendations: Match Key Parameters Based on Process Requirements

Working Pressure and Temperature

HDPE + ceramic powder granulation typically requires high pressure (30–50 MPa) and high temperature (200–250°C). A screen changer with a pressure rating ≥50 MPa and a maximum operating temperature ≤350°C (e.g., electric heating/thermal fluid heating models) should be selected.

Filter Area and Mesh Precision

The higher the ceramic powder content, the larger the required filter area. For example, for HDPE + 40% ceramic powder, a screen changer with a filter area ≥0.1m² is recommended, with mesh precision selected based on ceramic powder particle size (typically 100-300 mesh).

Sealing Performance and Wear Resistance

Prioritize rigid sealing structures with sealing components made of high-alloy steel (e.g., H13 steel) that have undergone special heat treatment (e.g., quenching + tempering), with a hardness of HRC ≥ 58, to ensure no material leakage during long-term use.

The HDPE ceramic powder plastic pelletizing dual-column screen changer addresses filtration efficiency, production continuity, and product quality issues in high-filler, high-wear conditions through core features such as dual-channel design, rigid sealing, and automated control. In practical applications, the appropriate model should be selected based on ceramic powder content, particle size distribution, and process requirements (e.g., pressure, temperature) to achieve the optimal balance between cost and performance.