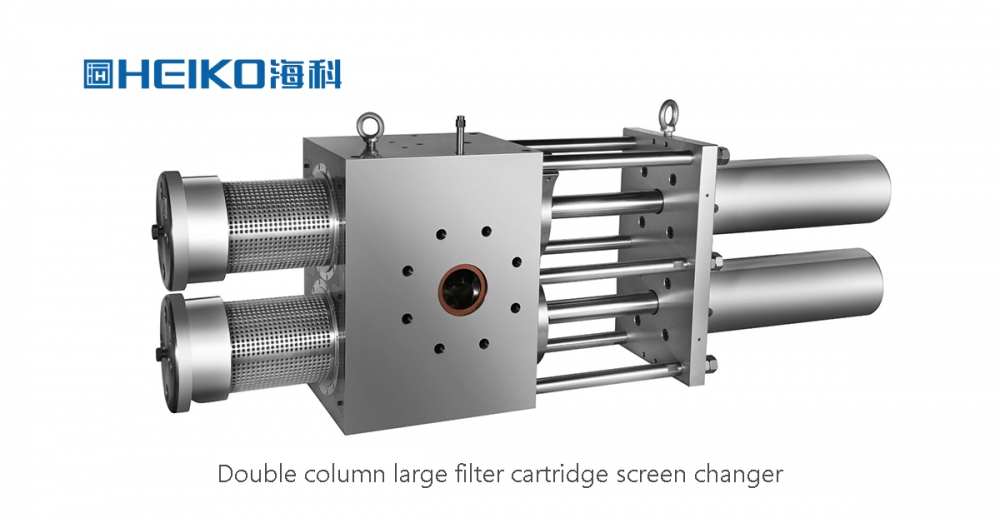

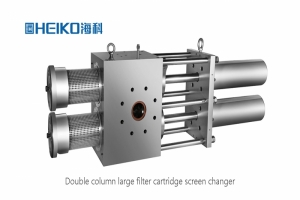

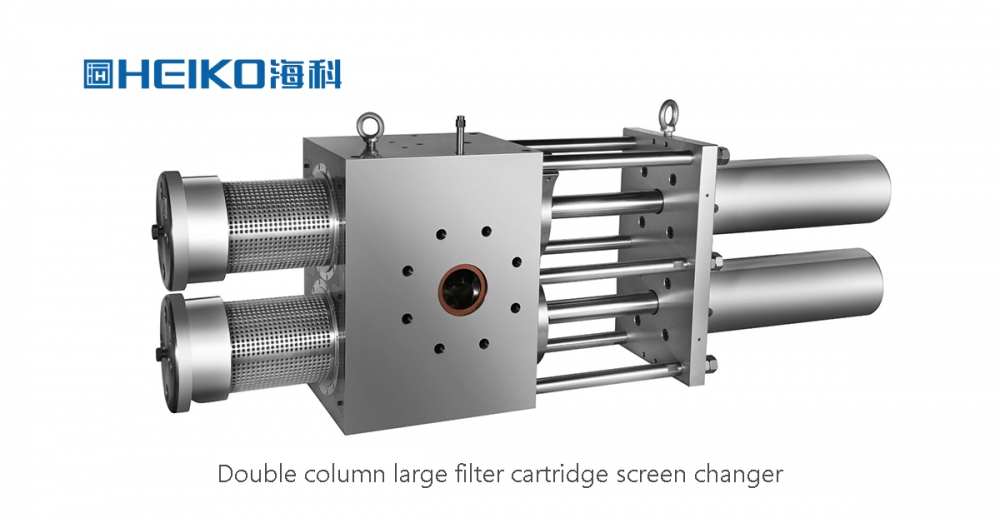

The main structural features of the double-column hydraulic screen changer are as follows:

Main Structure

Features a double-plunger, double-station design, with each plunger equipped with an independent flow channel and filter screen. During normal operation, both screens filter the melt simultaneously. During screen changes, one screen continues to operate while the other is replaced, ensuring continuous production.

Sealing and Materials

Sealing Method: Rigid sealing structure without mechanical seals, suitable for high-pressure and high-temperature environments (such as plastic pelletizing and pipe production), effectively preventing material leakage.

Materials: The main body and plungers are made of alloy steel with nitriding treatment, featuring a surface roughness of Ra ≤ 0.4 μm, high wear resistance, and extended service life.

Operating Mode

Alternate Screen Replacement: When screen impurities accumulate to a certain level, the hydraulic system controls the plunger to alternately push out the main body, completing the screen replacement.

Material Venting: During screen replacement, the material venting system removes gases from the material to prevent production interruptions or product defects.

Performance Optimization

Flow Channel Design: Optimized flow channel structure (e.g., honeycomb plates, elliptical flow channels) reduces fluid shear force, minimizing material retention and degradation risks.

Application Scenarios

Suitable for high-capacity, continuous production (e.g., cast film, pipes, sheets, etc.), particularly for recycled plastic processing and applications involving high proportions of recycled plastic.

Email: sale@heikomachinery.com

WhatsApp: +86 138 0371 7447