Melt pump in the wire drawing extrusion line has significant application value, its core role is reflected in the stability of the extrusion process, improve product quality, optimize energy consumption and equipment life in three aspects. The following is a specific analysis:

First, stabilize the extrusion process, eliminate process fluctuations

Accurate control of pressure and flow

Drawing production is extremely sensitive to the melt pressure fluctuations, fluctuations will lead to uneven wire diameter, wire breakage and other issues. Melt pump through the positive displacement transport principle, the extruder output of the melt pressurization and stabilization, so that the pressure fluctuations are controlled within ± 1%. For example, in the production of bi-directional oriented polypropylene film (BOPP), the introduction of melt pumps, film thickness deviation from the traditional process of 5% down to less than 1%, this principle also applies to the drawing line, can significantly improve the uniformity of the wire diameter.

Linear Extrusion Characteristics

The capacity of the melt pump is essentially linearly related to the rotational speed, and the flow rate can be precisely predicted when the speed is changed. This makes it easy to synchronize with upstream and downstream equipment (e.g. haul-offs, winders) for automated production. For example, through the pump inlet/outlet pressure and temperature feedback, the pump speed can be adjusted in real time to match the drawing speed, to avoid wire breakage or wire diameter fluctuations due to speed mismatch.

Second, improve product quality to meet the demand for precision

Reduce scrap rate

In wire drawing production, uneven material dosing, barrel temperature fluctuations, screw speed pulsation and other problems are difficult to avoid. Melt pump can eliminate dosing errors, weaken the upstream process fluctuations, and quickly enter a stable working state. For example, in the field of medical catheters, optical films and other high-end products, production lines equipped with melt pumps can control the dimensional accuracy in the micron level, and this technology is also applicable to high-precision wire drawing needs (such as fiber optic coating layer, special alloy wire).

Adaptation to heat-sensitive materials

Melt pumps reduce screw back pressure, reduce shear heating, and avoid over-plasticization or degradation of materials. This feature is particularly important for heat-sensitive materials such as PVC and TPUR. For example, in PVC wood-plastic profile drawing, melt pump and twin-screw extruder with different wood powder ratio can be adapted to the needs of the material at the same time to prevent the material due to high-temperature decomposition caused by the coarsening of the wire diameter or surface roughness.

Third, optimize energy consumption and equipment life, reduce the overall cost

low-temperature extrusion, prolong the life of the equipment

melt pump will be transferred to the pump body to complete the decompression function of the extruder, so that the extruder can be in a low-pressure low-temperature state work. This not only reduces the mechanical energy conversion heat by 30%, but also reduces the axial force borne by the screw, extending the screw life. For example, the introduction of melt pumps in a multinational packaging company, the annual power savings are equivalent to 42,000 tons of carbon dioxide emissions, while equipment maintenance costs are reduced by 20%.

Increased yield and energy efficiency

With less leakage, melt pumps can build up head pressure more efficiently than extruders, thus increasing yield. In chemical fiber spinning, for example, melt pumps provide stable delivery of polymer melts with viscosities in excess of 10,000 Pa-s, avoiding yield losses due to shear fracture of reinforcing fibers. In addition, precise temperature control reduces heating power by 20%, further reducing energy consumption.

Typical Application Scenarios

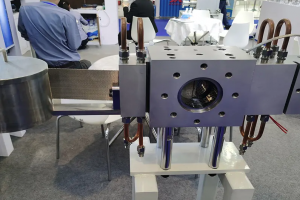

Chemical Fiber Spinning

In melt spinning of polyester, nylon, etc., melt pumps are required to continuously and stably transport polymer melts above 300℃. Special design of melt pump (such as herringbone gear pump) can avoid fiber breakage, to ensure uniformity of fiber. For example, after the introduction of German melt pump technology in a domestic enterprise, the diaphragm puncture strength from 300g/μm to 500g/μm, the yield rate exceeded 95%.

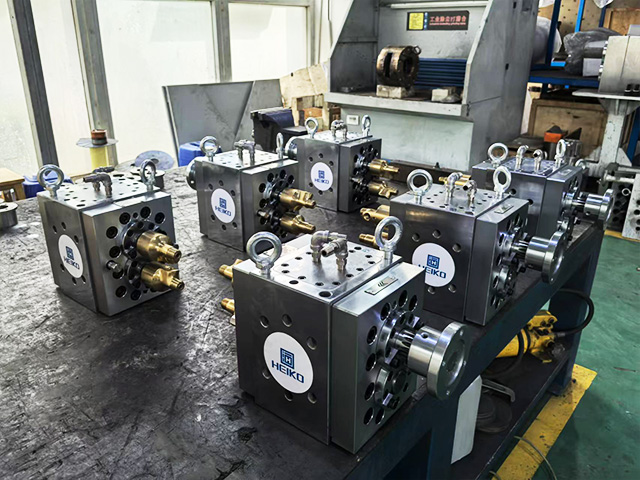

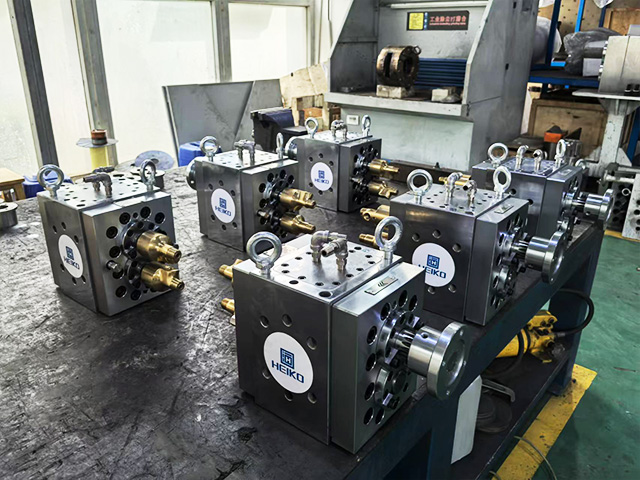

Metal 3D printed filament

The metal 3D printed gear parts of the melt pump make its pressure resistance level break through 100 MPa, which can stably convey high-temperature alloy melts to meet the demand for high-strength filaments in the aerospace field.

Plastic Recycling Drawing

In recycled material processing, melt pumps homogenize viscosity fluctuations caused by raw material differences. For example, after a European company used a two-stage melt pump system, the melt index fluctuation range of recycled HDPE is narrowed from ± 15% to ± 3%, so that the recycled plastics can be successfully used in food-contact grade packaging drawing.

melt pumps have become a core component of wire drawing lines by stabilizing pressure and flow, improving dimensional accuracy, and optimizing energy consumption and equipment life. Its application scenarios have expanded from traditional plastic wire drawing to chemical fiber, metal, recycled materials and other fields, the future with the integration of precision manufacturing and intelligent control technology, melt pumps will be in more industrial scenarios to show the irreplaceable value.