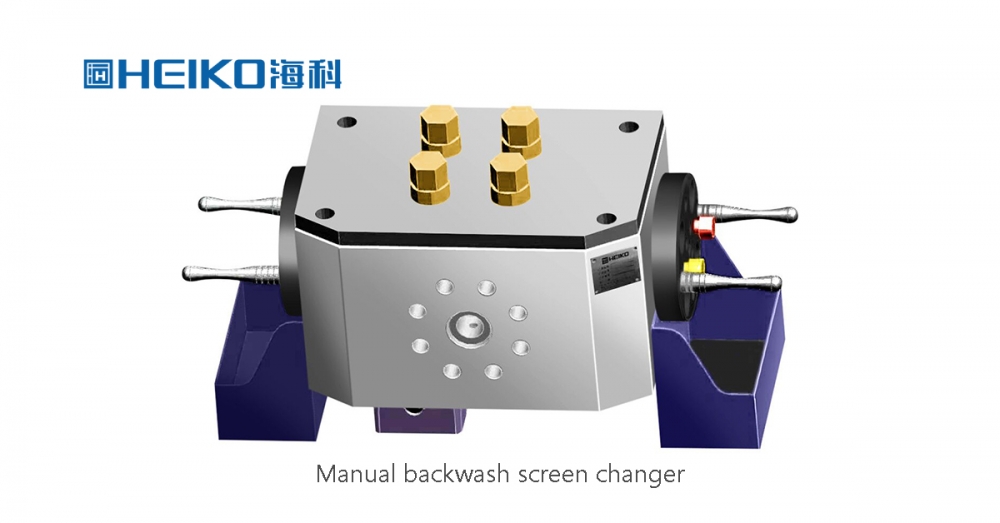

Screen changers play a central role in engineering plastic extrusion production lines, filtering impurities, improving quality, ensuring continuous production, and protecting equipment. Their technological evolution and process adaptability directly impact the yield rate of high-end products and production costs.

Typical application scenarios in engineering plastic production

Production of high-filler modified materials

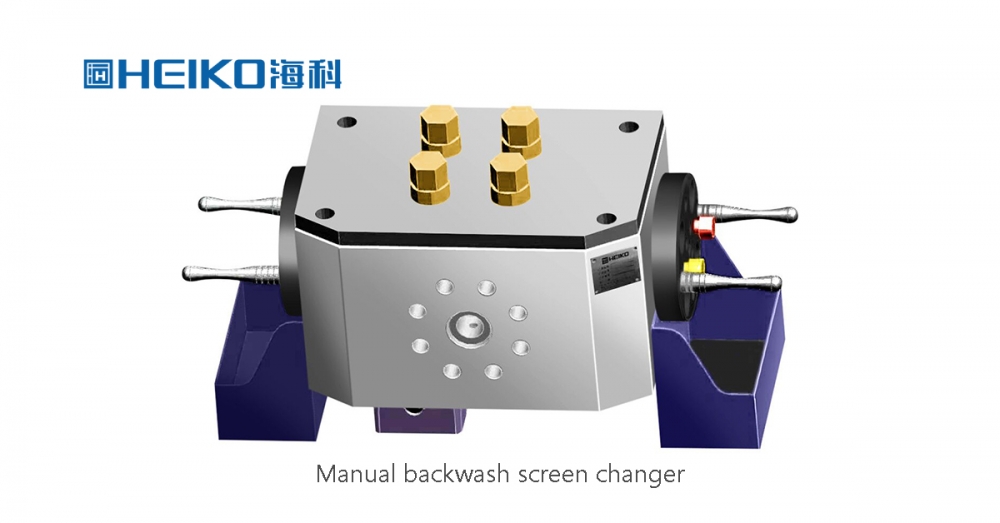

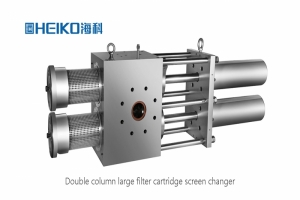

When producing glass fiber/mineral-reinforced plastics with a filler content exceeding 40%, traditional extruders are prone to screen blockage due to excessively high melt viscosity (up to 20,000 Pa·s). Screen changers enable continuous production by quickly switching screens (e.g., a dual-column screen changer can complete a switch in 0.3 seconds), avoiding production losses caused by shutdowns for cleaning (a single shutdown can result in losses of up to 500 kg/hour).

Precision Product Manufacturing

When producing high-end products such as medical catheters and optical films, the pressure and flow stabilization characteristics of the screen changer are critical. For example, when producing BOPP film with a thickness of only 5 μm, the screen changer can control melt pressure fluctuations within ±0.5 MPa, ensuring film thickness deviation ≤1% and meeting ISO Class 5 cleanliness requirements.

Recycled Material Regeneration

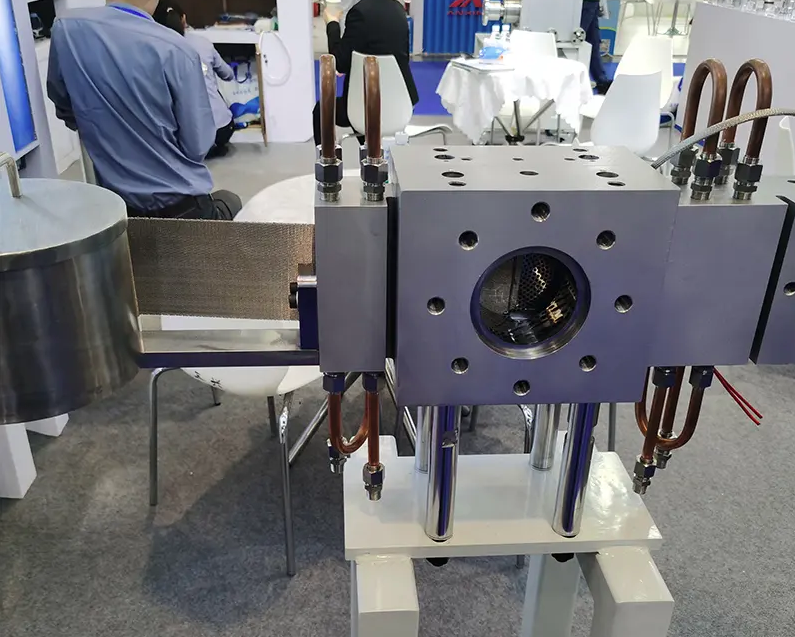

Engineering plastic recycled materials often contain non-plastic impurities such as paint and rubber. The screen changer uses multi-stage filtration (e.g., coarse filtration with an 80-mesh filter followed by fine filtration with a 200-mesh filter) to remove over 99% of impurities, reducing the melt flow rate (MFR) fluctuation range of recycled materials from ±30% to ±5%, achieving virgin material quality standards.

Selection Recommendations

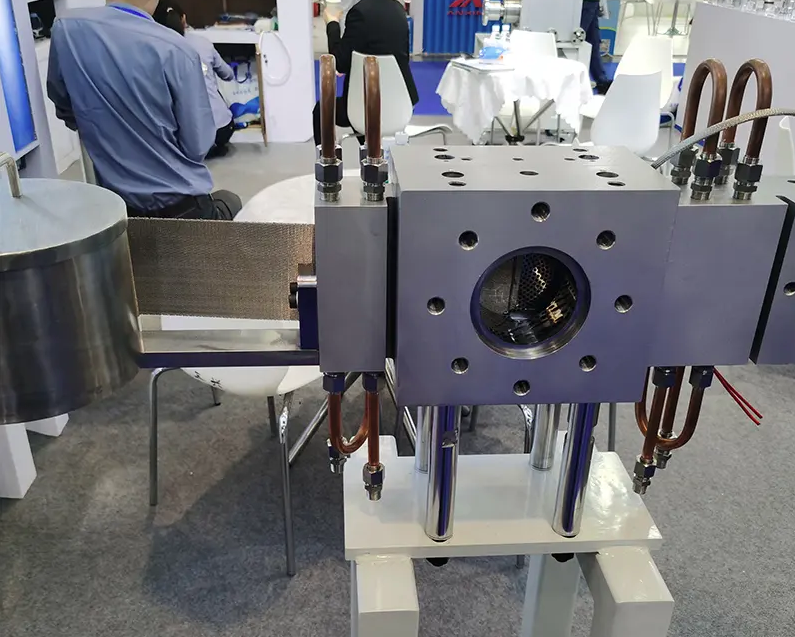

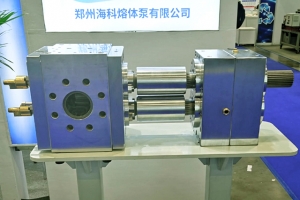

High-filler material production: Prioritize dual-column or belt-type screen changers to address the filtration requirements of high-viscosity melts.

Precision product manufacturing: Select intelligent screen changers with melt pressure feedback control to achieve automatic compensation for pressure fluctuations.

Recycled material regeneration: Adopt a multi-stage filtration system (e.g., coarse filtration + fine filtration combination) to enhance impurity removal efficiency.

Ultra-high-pressure conditions: Select reinforced screen changers with pressure compensation mechanisms (e.g., tungsten alloy wear-resistant sleeves), which can achieve a service life over five times longer than standard models.

Typical cases and industry recognition

Automotive parts manufacturing

An automotive parts supplier reduced the defect rate of “white spots” on the surface of glass-fiber-reinforced PA66 intake manifolds from 8% to 0.5% after installing a screen changer, and the mold service life was extended by 2 times.

High-end film production

A certain optical film manufacturer adopted an intelligent screen changer system, reducing film thickness deviation from ±3% to ±0.8% and increasing product pass rate to 99.5%.

Recycled Material Regeneration

A recycled material processing company used multi-stage filtration technology with a screen changer to reduce the MFR fluctuation range of recycled PA6 from ±30% to ±5%, successfully entering the automotive interior market with an annual processing capacity of 10,000 tons of recycled materials.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447