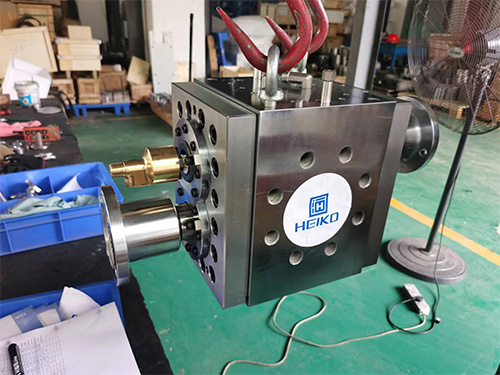

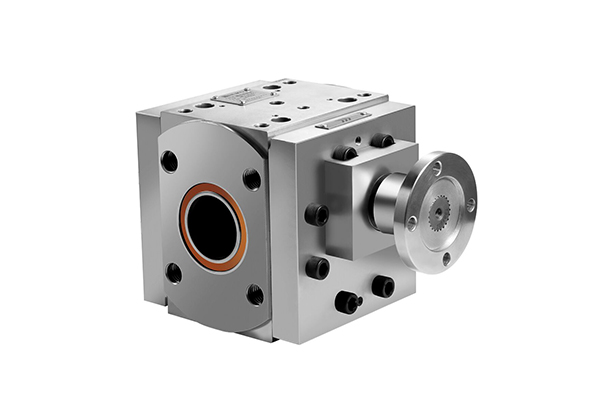

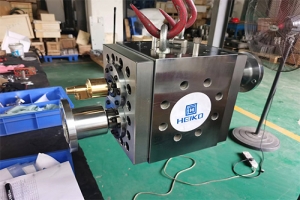

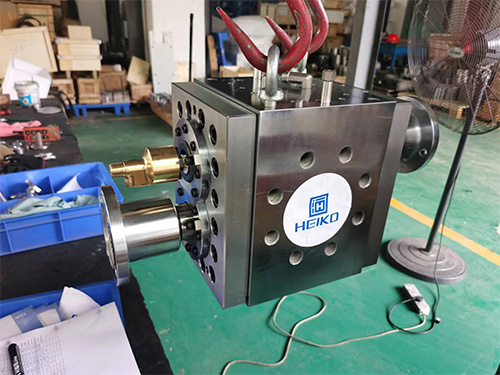

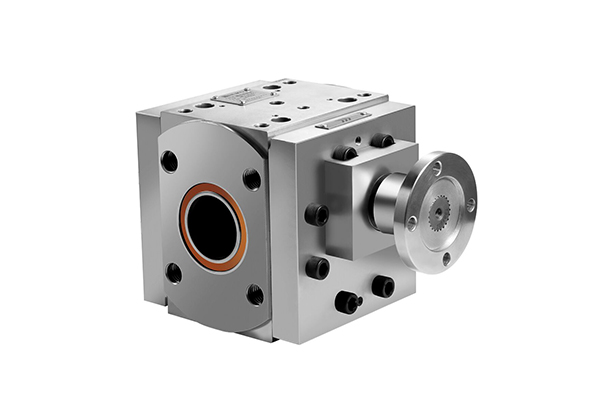

Rubber Extruder Melt Pump (Rubber Melt Gear Pump) is the core equipment of rubber and elastomer extrusion system, and its application scope covers the precise conveying and metering of high-viscosity, heat-sensitive materials, the specific application scenarios and advantages are as follows:

I. Core application areas

Rubber products extrusion molding

Applicable materials: polybutadiene rubber (BR), chloroprene rubber (CR), ethylene propylene diene trioxide (EPDM), styrene-butadiene rubber (SBR), nitrile rubber (NBR), natural rubber and so on.

Typical products: seals, hoses, tapes, tire treads, shock absorbing mats, rubber flooring, etc.

Function: Installed between the extruder outlet and die head, it realizes melt pressurization, pressure stabilization and accurate metering to ensure the dimensional stability and surface quality of extruded products.

Processing of elastomers and easily degradable plastics

Applicable materials: TPE (thermoplastic elastomer), TPU (polyurethane elastomer), PVC (polyvinyl chloride) and other heat-sensitive materials.

Advantage: The pump chamber finish is mirror grade (Ra≤0.2μm), avoiding material residual degradation, while reducing downtime for cleaning through self-cleaning runner design.

Extrusion of Co-mingled Modified Materials

Application Scenario: Rubber and Plastic Co-mingling (e.g. Rubber+PP, Rubber+PE), Filling Modification (e.g. Carbon Black Filling Rubber).

Effect: The melt pump stabilizes the flow rate output, ensures uniform dispersion of the co-mingled materials, and improves the consistency of the mechanical properties of the products.

Typical application cases

Automotive sealing strip production line

After configuring the rubber melt pump, the extrusion speed is increased by 25%, the scrap rate is reduced from 8% to 2%, and the annual saving of raw material cost is more than one million yuan.

Medical Rubber Catheter Extrusion

With the linear output characteristic of melt pump, it realizes the tolerance of catheter O.D. ±0.02mm, which meets the requirement of ISO 10555 standard.

Wood-plastic composite material extrusion

Combined with wood-plastic special twin-screw extruder, it produces skirting line, door set line and other profiles, solves the problem of poor melt fluidity caused by wood powder filling, and improves the surface finish of the products by 1 level.

Rubber extruder melt pumps have become the key equipment for the extrusion of rubber products, elastomers and co-mingled materials by stabilizing pressure flow, self-cleaning and energy-saving features. Its application not only improves product quality and production efficiency, but also brings significant economic benefits to enterprises by reducing energy consumption and scrap rate.