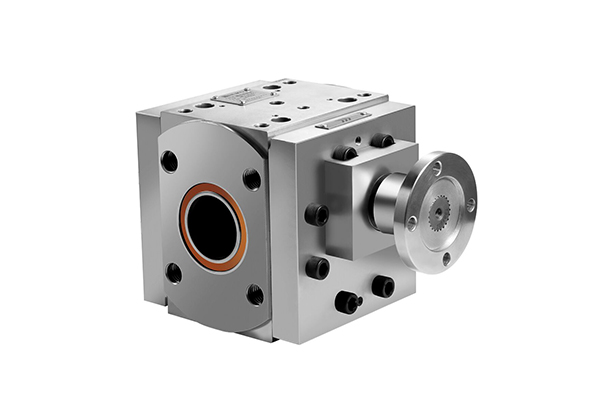

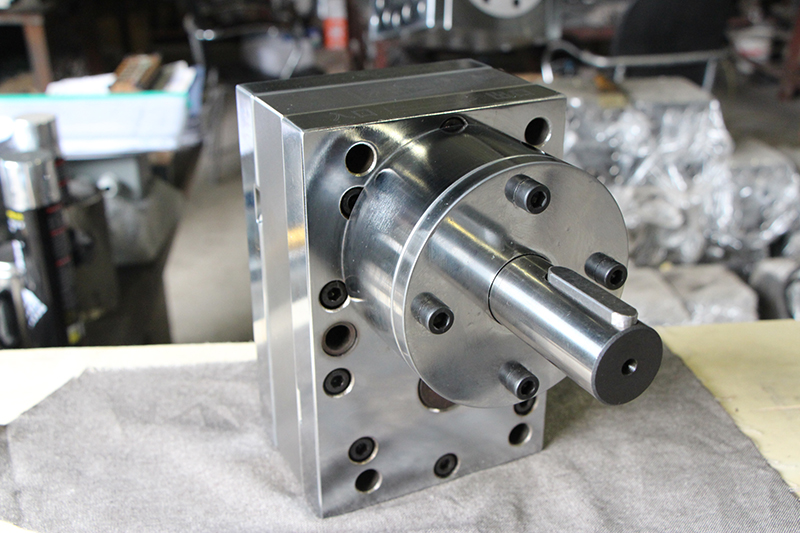

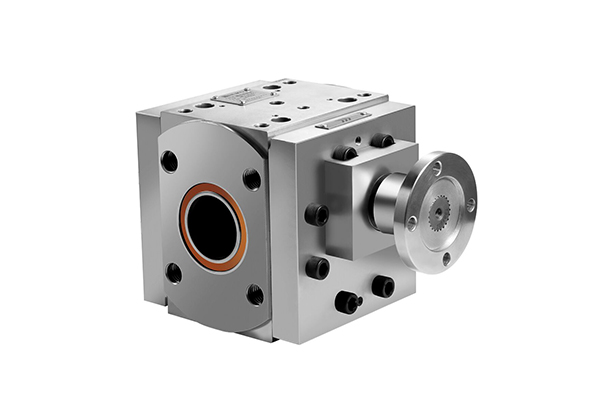

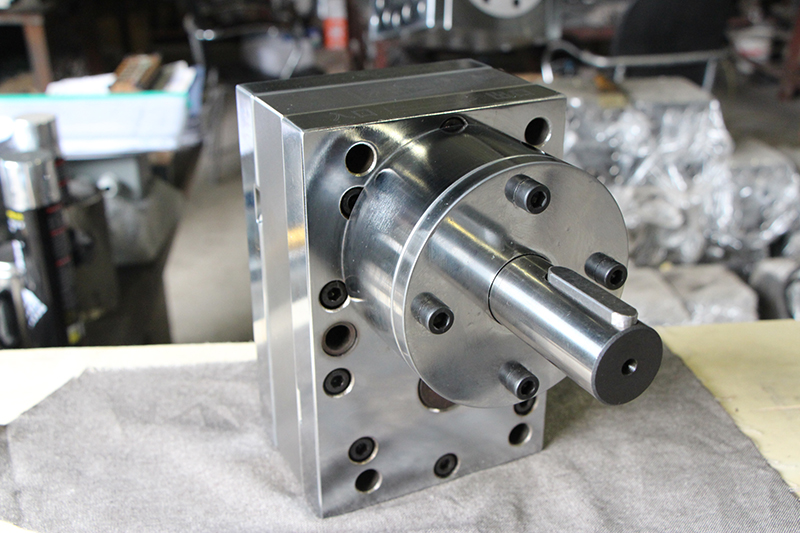

High-temperature melt gear pump in chemical fiber spinning in the specific application of the following aspects:

First, stable delivery of melt

In the chemical fiber spinning process, high temperature melt gear pumps can stably deliver high temperature and high viscosity polymer melt. This stability is critical to the spinning process, because it ensures the continuity and uniformity of the melt in the spinning process, thereby improving the spinning efficiency and product quality.

Second, accurate metering and control

High temperature melt gear pumps have precise metering function, can accurately control the melt delivery. This is very important for chemical fiber spinning, because different spinning processes require different amounts of melt. Through accurate metering, you can ensure that the supply of melt in the spinning process to match the demand, to avoid waste and insufficiency.

Improvement of spinning quality

The use of high temperature melt gear pumps can significantly improve spinning quality. Because it can be stable delivery of melt and accurate metering, so you can ensure that the spun fiber with uniformity and good physical and mechanical properties. In addition, high-temperature melt pumps can also reduce pressure fluctuations in the spinning process, thereby reducing fiber breakage and defects.

Fourth, adapt to a variety of chemical fiber materials

high temperature melt gear pump is suitable for a variety of chemical fiber materials spinning process, such as polyester fiber, polyamide fiber and so on. These materials have high viscosity and temperature sensitivity in the molten state, and the high temperature melt pump is designed for such high temperature and high viscosity melt. Therefore, it can be adapted to the spinning needs of different chemical fiber materials and provide them with stable and efficient conveying and metering services.

Fifth. Extend the life of the equipment and reduce energy consumption

The use of high temperature melt gear pumps in the chemical fiber spinning process can also extend the life of the equipment and reduce energy consumption. Because it can stabilize the output pressure and reduce the residence time of the melt in the screw barrel, so it can reduce the wear and tear between the screw and the screw barrel, extending the service life of the equipment. At the same time, by accurately metering and controlling the amount of melt delivered, unnecessary waste of energy can also be avoided.

In summary, high temperature melt pump has a wide range of application prospects and important application value in chemical fiber spinning. It can not only transport the melt stably, measure and control accurately, improve the spinning quality, but also adapt to a variety of chemical fiber materials and prolong the life of the equipment and reduce energy consumption.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447