Extruder plus screen changer is mainly based on the following reasons:

1, filter impurities, improve product quality: plastic, rubber and other raw materials in the production, transportation and storage process, easy to mix a variety of impurities, such as metal particles, carbonized material, paper and so on. The filter in the screen changer can effectively intercept these impurities and ensure that the extruded material is pure. For example, in the production of plastic products, if the impurities are not filtered, it will lead to defects on the surface of the product, holes, bubbles and other problems, affecting the appearance and performance of the product, and the screen changer can avoid these situations and improve product quality.

2, to protect downstream equipment: impurities with the material into the downstream equipment, such as melt pumps, molds, etc., will cause serious wear and damage to these precision equipment. The screen changer can filter out the impurities before the material enters the downstream equipment, prolonging the service life of the equipment and reducing the number of repairs and costs of the equipment. For example, the runner of the mold is blocked or worn by impurities, which will affect the molding accuracy and quality of the products and increase the maintenance and replacement cost of the mold, and the screen changer can play a very good protective role.

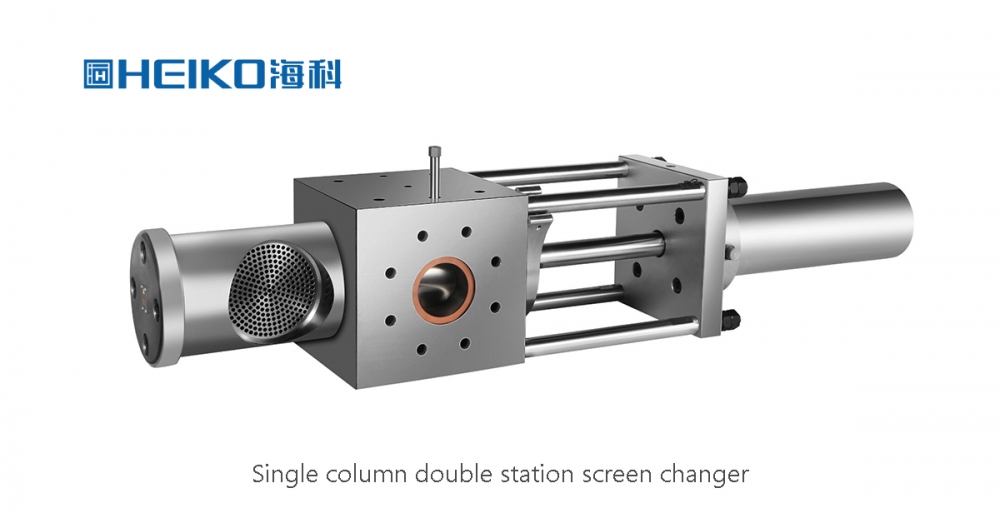

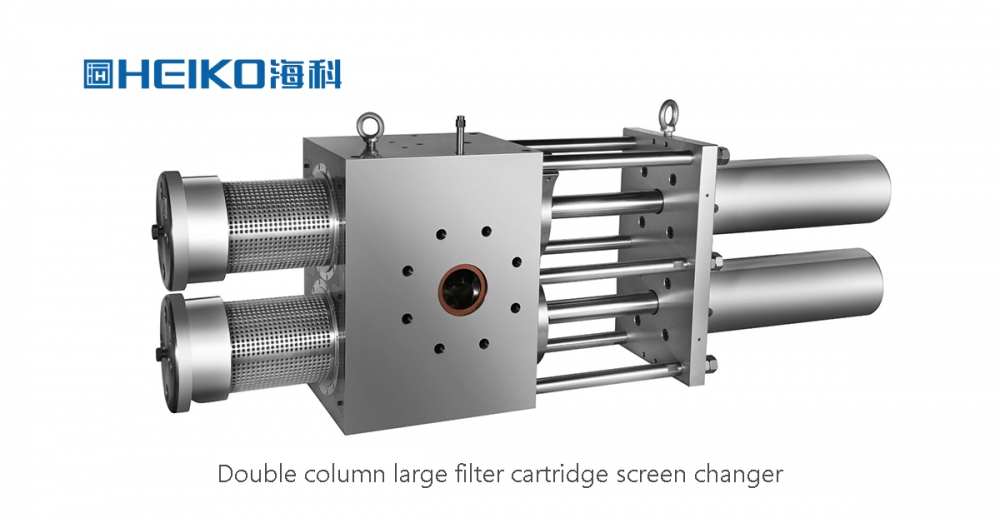

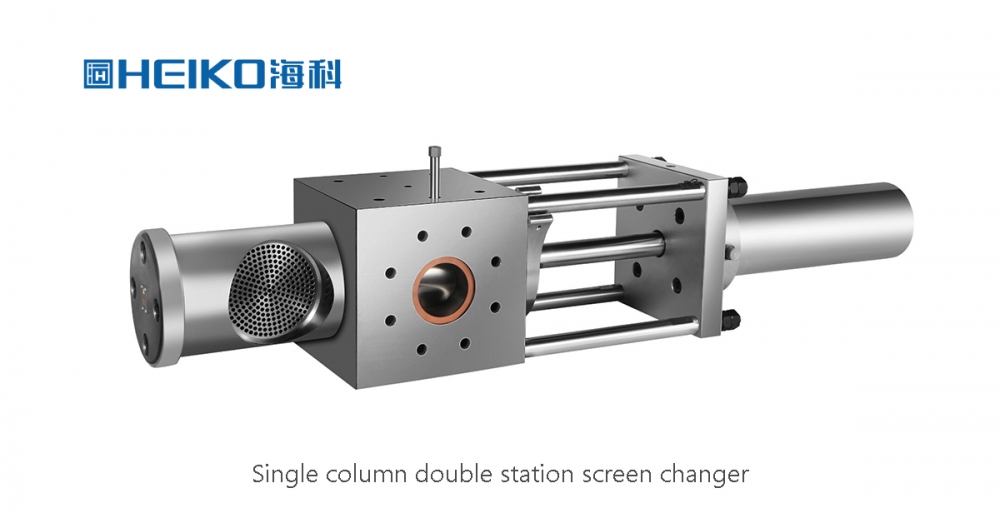

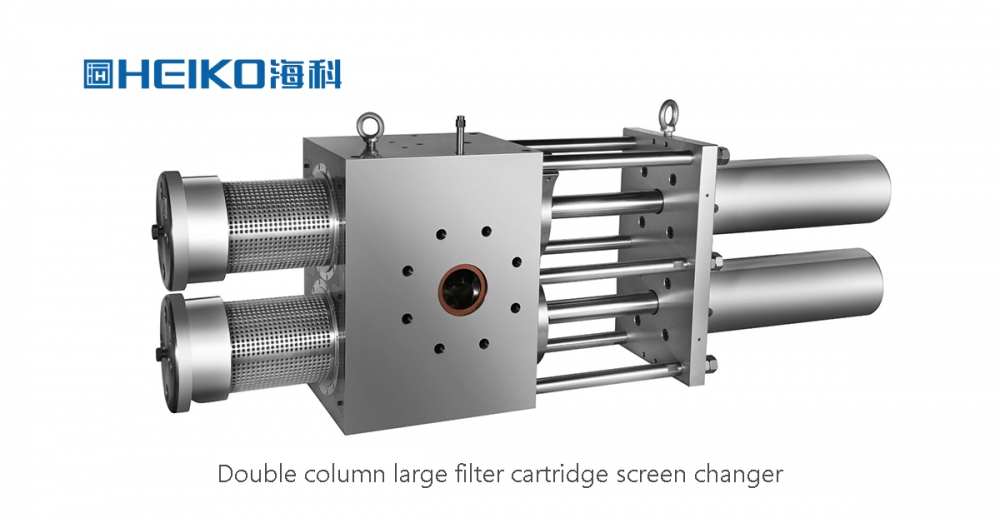

3, to maintain the continuity and stability of production: some screen changers have the function of online replacement of the screen, that is, without stopping the screen can be replaced. This can reduce the production interruption caused by the replacement of the screen, maintain the continuity of the production process and improve production efficiency. At the same time, the stable material filtration effect also helps to maintain the stability of pressure and flow in the extrusion process, to ensure product quality consistency.

4, to adapt to different production needs: different production processes and products have different requirements for material purity, by replacing different mesh or type of screen, the screen changer can flexibly adapt to these different production needs. For example, the production of high-precision plastic products, you may need to use a higher mesh, better filtration accuracy of the screen; and the production of some relatively low purity requirements of the product, you can use a lower mesh screen.

5, reduce production costs: Although the screen changer itself requires a certain investment, but in the long run, it can reduce the rate of scrap due to impurities, reduce equipment maintenance costs, improve production efficiency, thereby reducing overall production costs. Moreover, the rational use of screen changer can also extend the service life of raw materials, to avoid waste of raw materials due to impurities mixed in.

Email: sale@heikomachinery.com

WhatsApp: +86 138 0371 7447