Plastic extruder screen changer plays a vital role in the plastic extrusion production process, its standard and customized configuration selection directly affects the production efficiency and product quality. The following is a detailed analysis of the standard and customized plastic extruder screen changer:

First, the standard configuration

The standard configuration of plastic extruder screen changer usually includes the following key components:

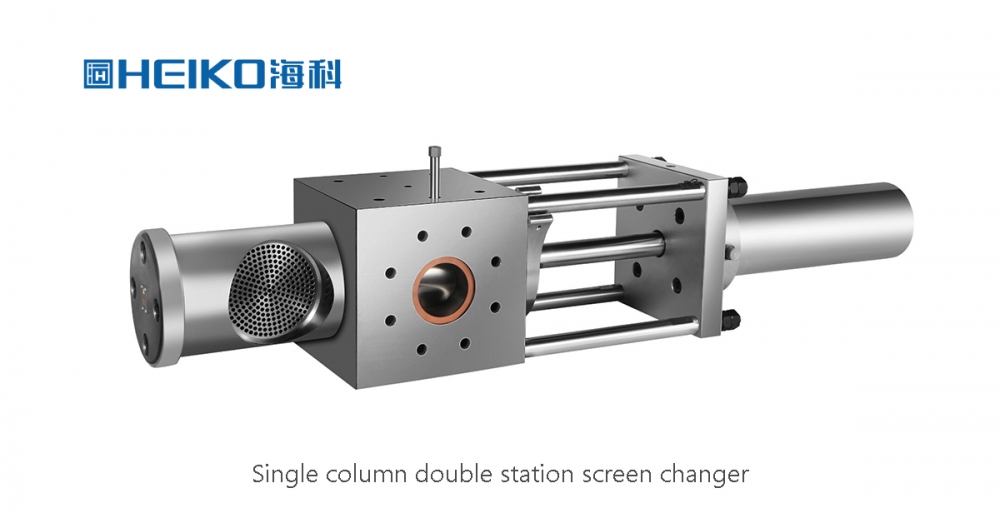

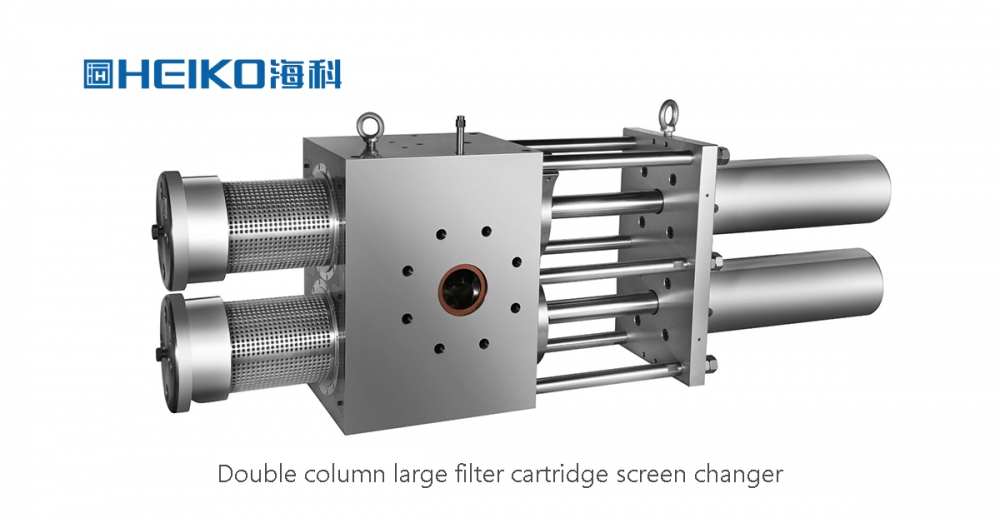

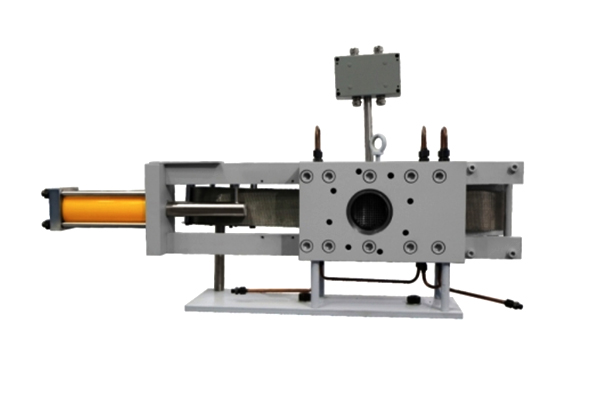

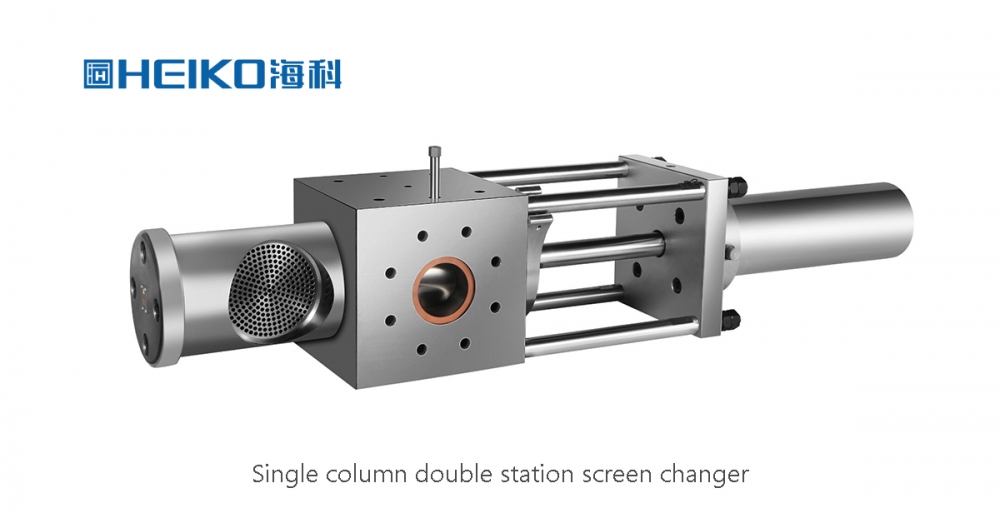

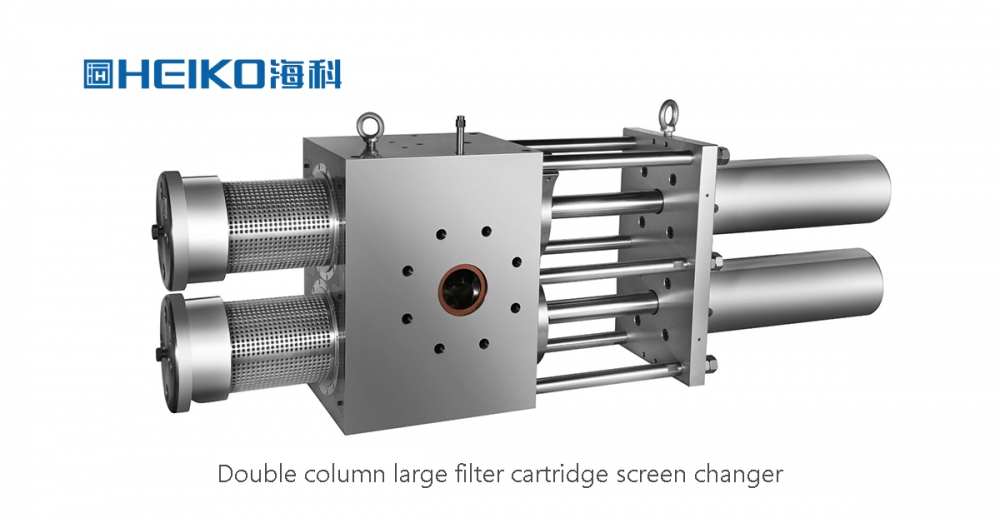

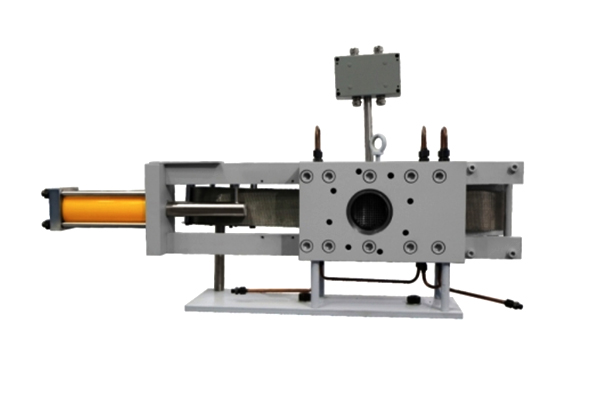

Screen changer body: the core structure of the screen changer, responsible for the installation of the screen and the implementation of screen changing operations. It is designed to ensure stable operation in high pressure and high temperature environments, while facilitating rapid screen replacement.

Accumulator Hydraulic Pump Station: Provides the necessary hydraulic power for the screen changer to ensure fast, smooth and reliable screen changing operations. The energy storage function helps to maintain the stability of the hydraulic system and reduce energy consumption during the screen changing process.

Heating device: Used to preheat the screen and plasticized material to ensure the fluidity of the material during the screen changing process and to prevent clogging problems caused by temperature drop. The heating method is usually external heating plate or heating ring, built-in heating tube or integrated heating method, or can be customized according to the requirements of the heat medium heating, in order to achieve energy saving and high efficiency.

Second, customized configuration

On the basis of the standard configuration, according to the customer's specific production requirements and process characteristics, plastic extruder screen changer can also be customized configuration to meet a wider range of application scenarios:

Electrical control cabinet: used to realize the automatic control of the screen changer. Through programming and setting, the electrical control cabinet can accurately control the screen changer's start, stop, screen changing time and other parameters, so as to improve the automation level and production efficiency of the production process.

Special material filter screen: According to the customer's requirements for filtration precision and corrosion resistance, special material filter screen can be customized. For example, for certain corrosive materials, you can choose a better corrosion-resistant screen material to ensure the stability and safety of the production process.

Additional safety devices: In order to further improve production safety, additional safety devices such as safety locks and pressure sensors can be added to the customized configuration. These devices can provide additional security during the screen change process to prevent safety accidents caused by misuse or equipment failure.

Third. Application Scenarios and Advantages

Plastic Extruder Screen Changer is widely used in the fields of pelletizing, PE/PP/PPR pipe production, sheet manufacturing, sheet processing, pigment film production, non-woven fabrics manufacturing and chemical fiber spinning. In these fields, the extruder screen changer provides a strong guarantee for the continuity of the production process and product quality with its efficient, stable and reliable screen changing performance. Its main advantages include:

Increased productivity: Reduced production downtime through fast and smooth screen change operations.

Ensure product quality: Precise screen changes and stable hydraulics ensure material uniformity and consistency during the extrusion process.

Reduced maintenance costs: standardized components and easy-to-change screen design reduce equipment maintenance costs and downtime.

Adaptability: Customized configurations can be made according to specific customer needs to meet the requirements of a wide range of production processes and material characteristics.

In summary, the selection of standard and customized configurations of plastic extruder screen changers should be based on customer-specific production requirements and process characteristics for comprehensive consideration. Through reasonable configuration selection, it can ensure the efficient, stable and reliable operation of the screen changer, thus improving production efficiency and product quality.

Email: sale@heikomachinery.com

WhatsApp: +86 138 0371 7447