The TPU pelletizing melt pump is a high-precision device specifically designed for the TPU (thermoplastic polyurethane elastomer) pelletizing process. Its core functions include the stable transportation, pressurization, and metering of melt through gear meshing, thereby enhancing pelletizing efficiency and product quality. The following analysis is conducted from three aspects: technical characteristics, application advantages, and selection recommendations:

I. Technical Characteristics

High-Precision Metering and Pressure Stabilization

The TPU pelletizing melt pump employs the principle of gear meshing, with a strictly proportional relationship between flow rate and rotational speed, enabling precise control of melt output and ensuring uniform pellet size. Its pressure stabilization function eliminates the impact of extruder pressure fluctuations on melt flow, minimizing product size tolerances, particularly suitable for TPU pelletizing scenarios with high precision requirements.

High-Temperature and High-Pressure Resistance Design

The pump body is typically made of high-temperature alloy steel or powder alloy steel, undergoing heat treatment processes such as quenching, tempering, and nitriding to achieve a hardness of 62-68HRC, capable of withstanding temperatures up to 350℃ and pressures up to 40MPa. The flow channel finish approaches a mirror-like surface, reducing melt residue and preventing the degradation of heat-sensitive TPU materials.

Self-Cleaning and Low Shear

Optimized flow channels and lubrication systems enable efficient self-cleaning, with a dead-angle-free design preventing material residue. The low shear characteristic reduces the risk of TPU molecular chain breakage, preserving material elasticity and physical properties, suitable for high-viscosity (up to 40,000Pa·s) melt transportation.

Modularity and Scalability

It supports parallel feeding from multiple small and medium-sized extruders, with centralized metering through the melt pump supplying large-scale dies, applicable to the production of large-diameter pipes, wide-format sheets, and other large products. The modular design facilitates matching with extruders of different specifications, reducing production line modification costs.

II. Application Advantages

Enhanced Production Efficiency

The melt pump transfers the pressure-reducing function of the extruder to the pump body, allowing the extruder to operate under low-pressure and low-temperature conditions, reducing leakage and increasing output. Meanwhile, its linear extrusion characteristic facilitates coordinated operation with upstream and downstream equipment (such as pelletizers), shortening the production cycle.

Reduced Energy Consumption and Costs

By stabilizing melt pressure and flow rate, it reduces the scrap rate and raw material loss. When combined with a co-rotating twin-screw extruder, the mixing quality and output are improved by approximately 25%, with significant energy consumption reduction.

Extended Equipment Lifespan

The melt pump undertakes high-pressure transportation tasks, reducing the axial force borne by the extruder screw and minimizing mechanical wear. Additionally, its high-temperature and high-pressure resistance characteristics reduce equipment failure rates and lower maintenance costs.

III. Selection Recommendations

Key Parameter Matching

The pump model should be selected based on TPU melt viscosity (1-40,000Pa·s), operating temperature (≤350℃), inlet and outlet pressure (0-40MPa), and output requirements. For example, high-viscosity TPU requires helical or herringbone gear pumps to enhance transportation capacity.

Heating and Drive Methods

Electric heating or heat medium channel heating methods are recommended to ensure uniform melt temperature. The drive system is advised to use a variable-frequency speed-regulating motor connected to the melt pump via a universal coupling to eliminate the impact of thermal deformation on coaxiality.

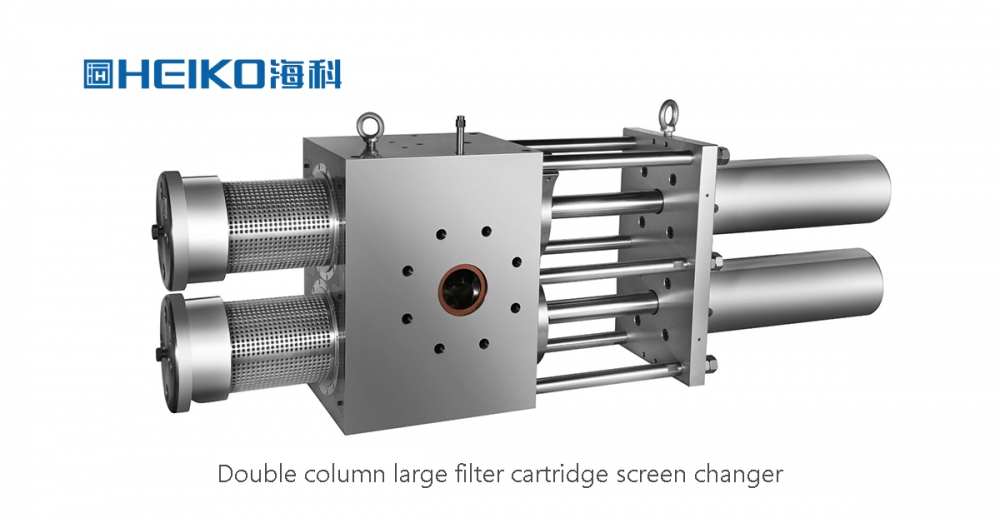

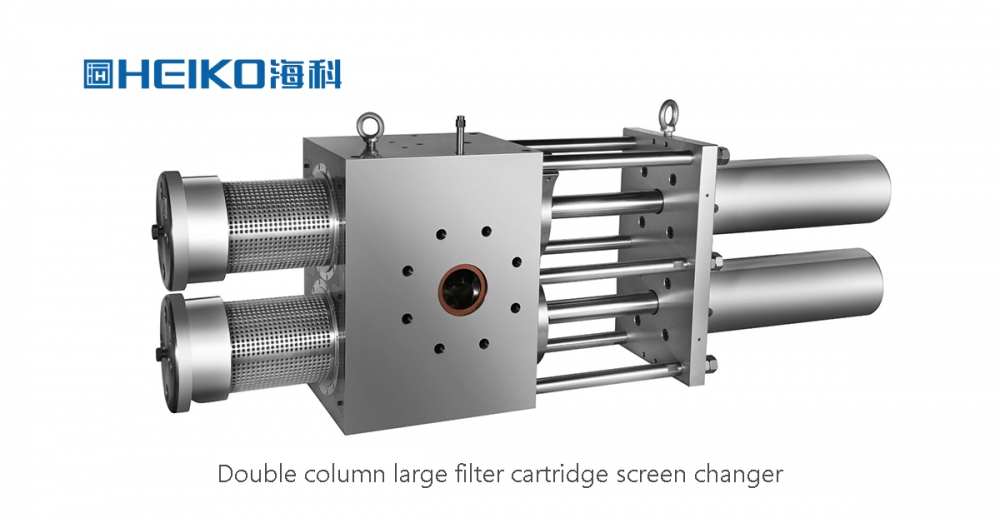

Supplier Selection

Priority should be given to enterprises with R&D experience in high-temperature melt pumps, such as Zhengzhou Heiko Machinery Co., Ltd. Their products cover series like MP-S, MP-M, MP-H, etc., with specifications ranging from 5CC to 25,000CC, supporting non-standard customization and providing PLC control systems, screen changers, and other ancillary equipment.

Email: sale@heikomachinery.com

WhatsApp: +86 138 0371 7447