The pelletizing extrusion screen changer is a critical piece of equipment in plastic pelletizing production lines, primarily used to filter impurities from the melt during the extrusion process, ensuring product quality and production continuity. Below is a detailed introduction covering its functional features, types, application scenarios, and selection recommendations:

Impurity Filtration

Intercepts solid particles, gels, and other impurities in the melt through a screen, preventing defects (such as black spots or crystal points) in subsequent processes.

Continuous Screen Change Without Shutdown

Adopts a dual or multi-station design, where one screen operates while the other is replaced, ensuring production continuity and minimizing waste generation.

Stable Pressure

Minimizes fluctuations in melt flow pressure during screen changes, avoiding product size instability or equipment damage caused by sudden pressure changes.

Automatic Control

Equipped with pressure sensors and hydraulic systems, enabling automatic detection and screen changing to reduce manual intervention.

High Temperature and Pressure Resistance

Suitable for high-temperature melts (e.g., molten states of PP, PE, PS, etc.), capable of withstanding the high-pressure environment of extruders.

II. Types and Structures

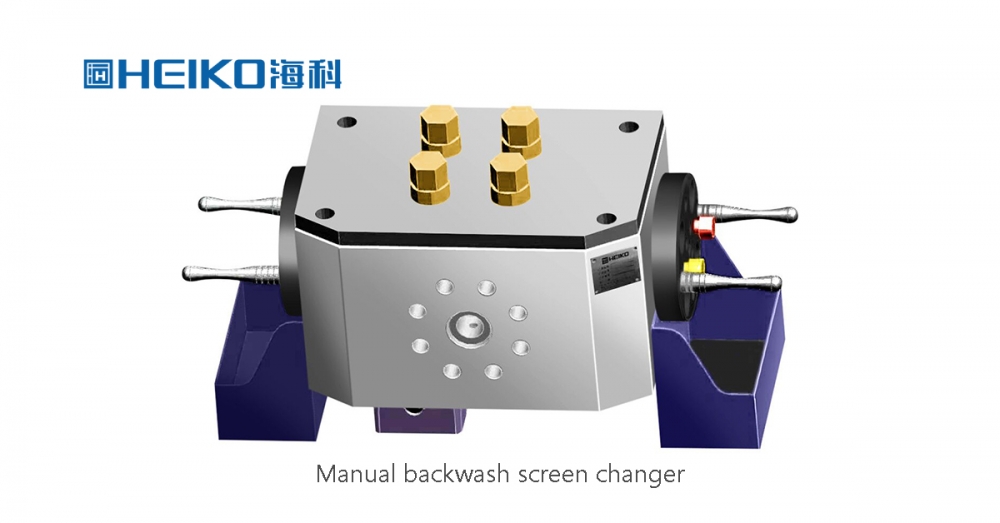

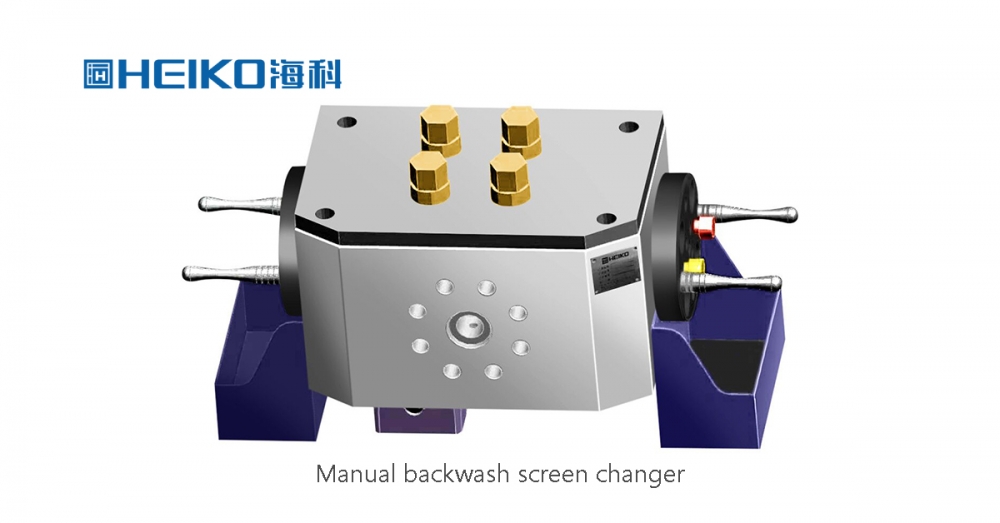

Manual Screen Changer

Simple in structure and low-cost, but requires shutdown for screen replacement, suitable for small-scale production or scenarios with low continuity requirements.

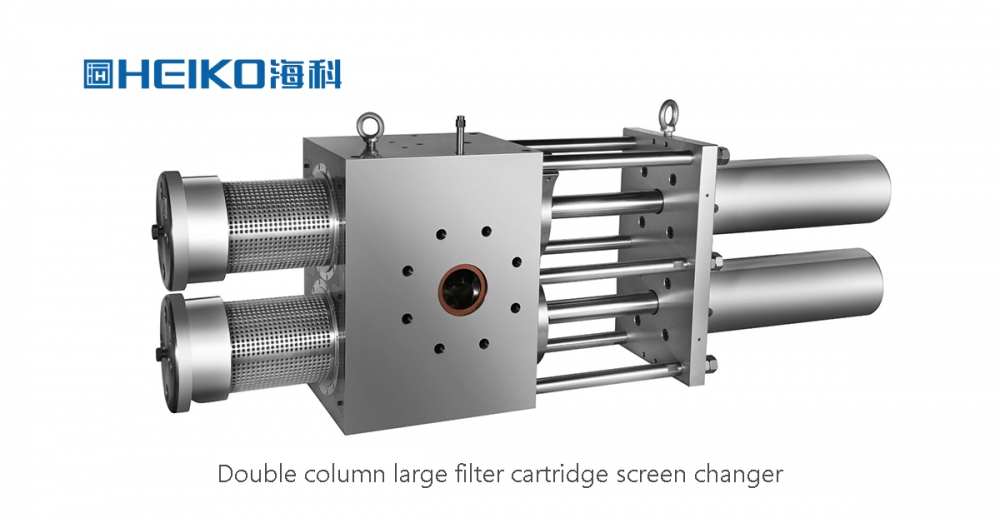

Hydraulic Automatic Screen Changer

Drives screen switching via a hydraulic system, enabling rapid screen changes (typically completed within seconds), suitable for large-scale continuous production.

Belt-Type Screen Changer

Utilizes a continuously moving screen belt, achieving continuous filtration without shutdown, suitable for high-output and high-purity requirement scenarios.

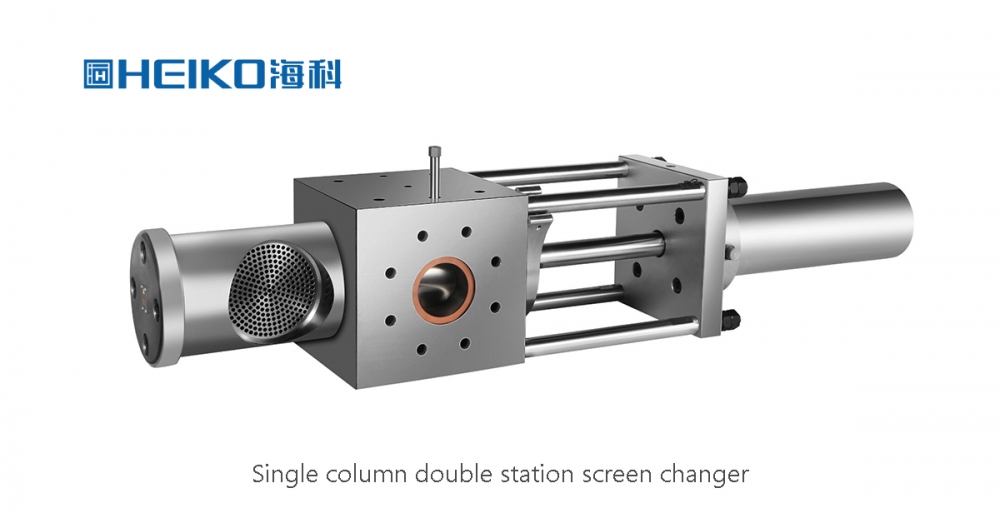

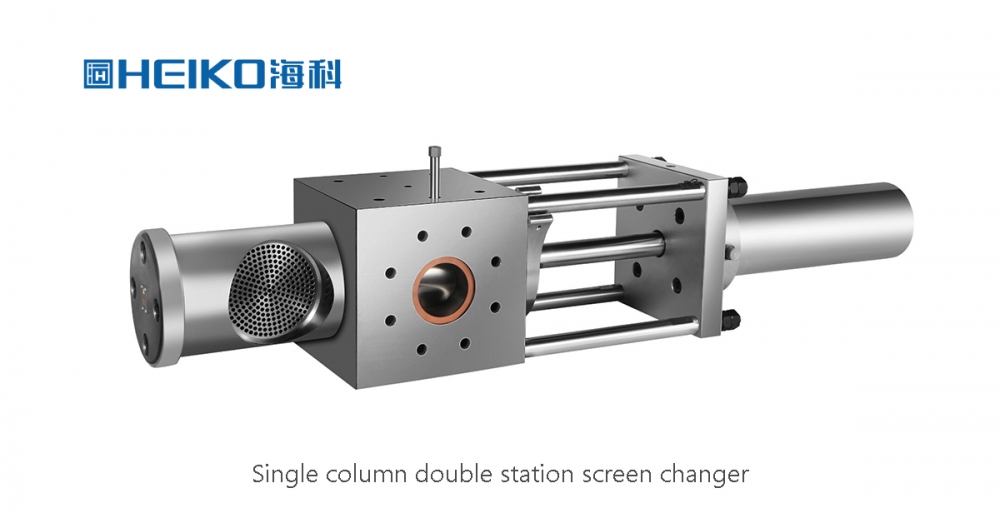

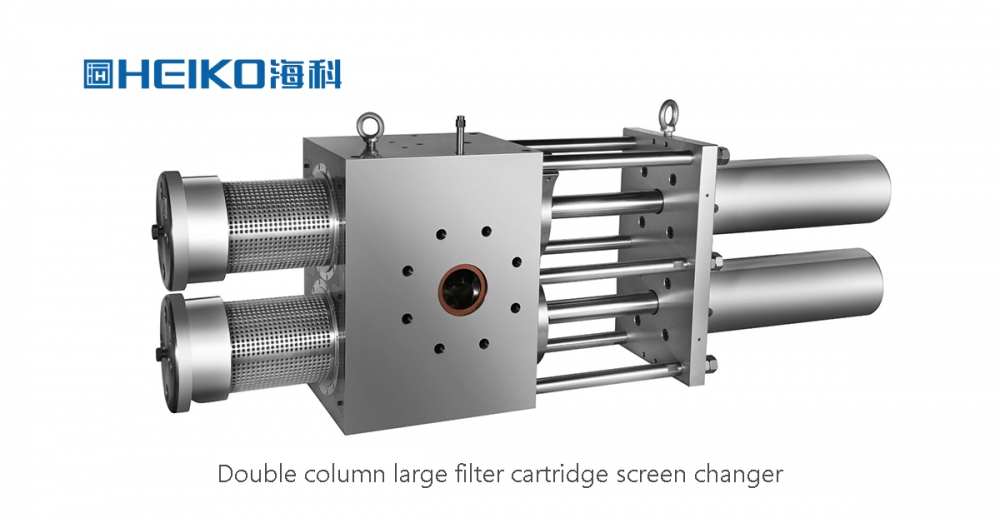

Dual-Plunger Screen Changer

Features alternating operation of two screens, ensuring uninterrupted melt flow during screen changes, suitable for production lines with extremely high continuity requirements.

III. Application Scenarios

Plastic Pelletizing

Filters impurities from recycled materials in plastic recycling and modified plastic production, enhancing the quality of recycled pellets.

Extrusion Molding

Used in extrusion lines for pipes, sheets, films, etc., ensuring product surface finish and mechanical properties.

Chemical Fiber Production

Filters melts during the spinning process to prevent fiber breakage or strength degradation.

IV. Selection Recommendations

Selection Based on Output

For low-output production lines: Manual screen changer or single-station hydraulic screen changer.

For high-output production lines: Dual-station hydraulic screen changer or belt-type screen changer.

Selection Based on Material Characteristics

For high-viscosity materials: Choose a screen changer with a large bore and high pressure resistance.

For corrosive materials: Choose a screen changer made of stainless steel or with special coatings.

Selection Based on Automation Level

For fully automated production lines: Equip with PLC-controlled automatic screen changers to achieve linkage with extruders.

For semi-automated production lines: Choose manual or semi-automatic screen changers to reduce costs.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447