Plastic extrusion screen changers play an important role in profile extrusion lines, mainly in the following areas:

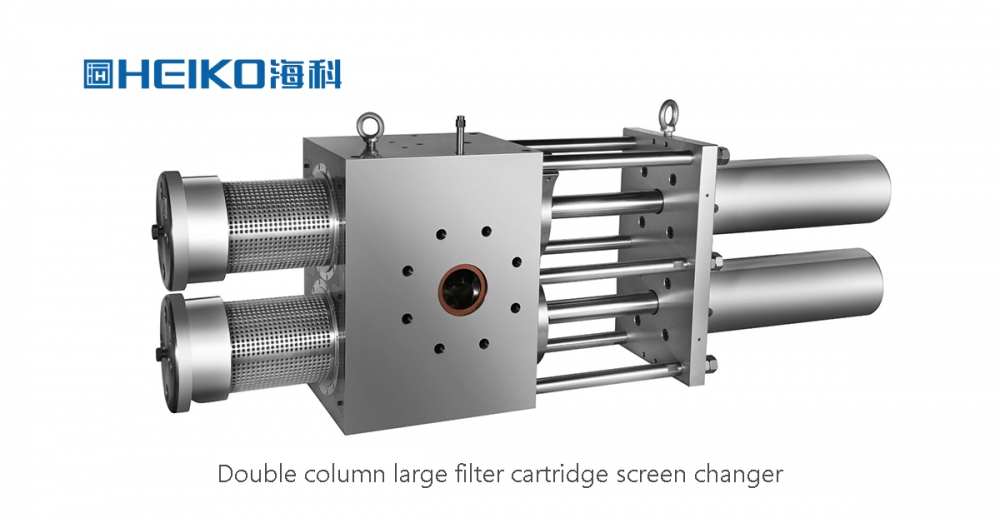

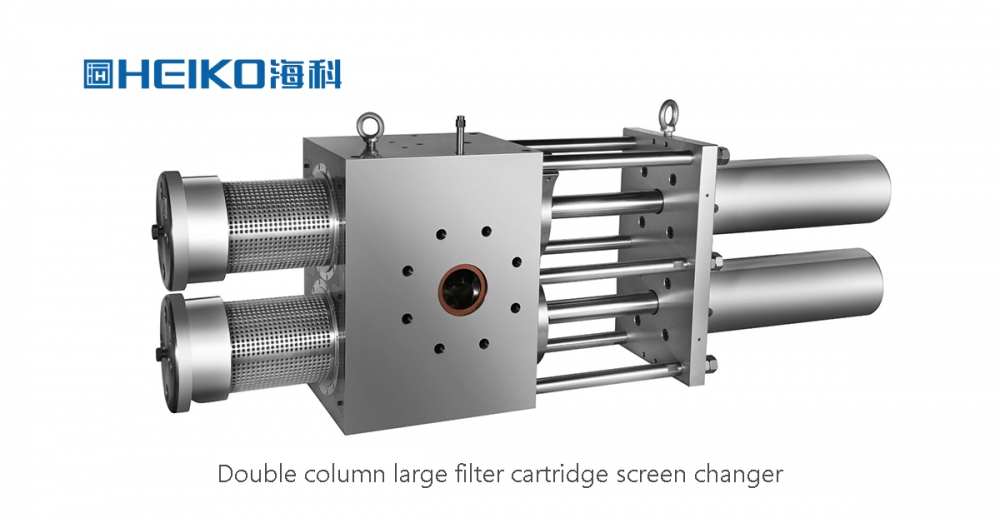

Filtering impurities: During the plastic extrusion process, the plastic melt may contain foreign particles, impurities and unplasticized fine plastic particles. These impurities, if they enter the extruder head, will lead to clogging of the flow channel, affecting the quality of the plastic products or even preventing normal production. The screen changer, through its internal filter, can effectively filter out these impurities, so that the pure melt enters the extruder head smoothly, thus ensuring the quality of plastic products. For the recycling of plastics and the production of fillers, the screen changer is even more indispensable, as it filters out all kinds of non-plastic substances in the recycled material, particles of low precision grades, and plastics with non-integrated characteristics.

Ensuring product quality: The same screen changer can be fitted with different grades of filtration according to the process requirements, in order to meet the process grade requirements of different products. For example, the production of high transparency requirements of the product can be used to choose a high mesh number of filter mesh. The material through the screen will produce a certain pressure rise, through the support of the small holes of the porous plate shunt effect on the plasticization of the material and mixing uniformity has a certain effect, so as to further improve the quality of the product.

Protect equipment: filtering out impurities can reduce the wear and tear of impurities on the extruder screw, head, die and other parts, prolonging the service life of the extruder equipment.

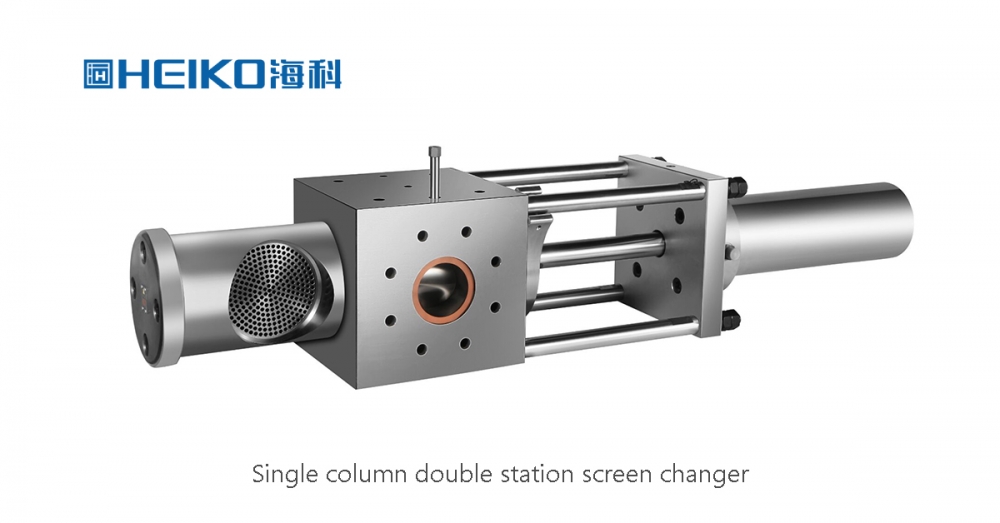

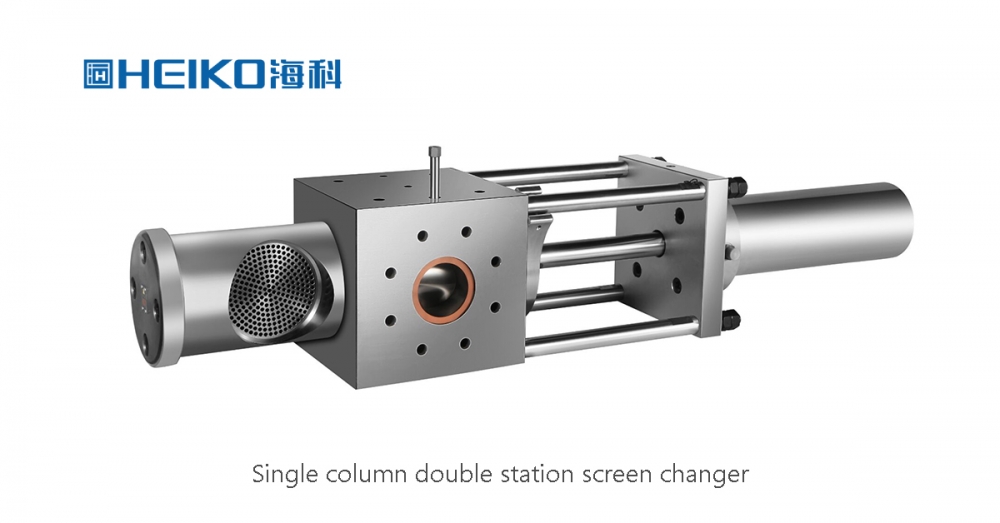

Enhance production efficiency: Some special structure screen changers can realize screen changing without stopping or when slowing down the extrusion speed, and the screen changer without stopping can ensure the least defective products, reduce the interruption of production, and improve the production efficiency.

Improvement of rheological behavior: The screen changer can change the rheological behavior of the material, change the rotating flow into linear flow, reduce the “winding pattern” on the surface of the product, and ensure the uniform distribution of the flow rate of the melt, which can help to improve the appearance quality of the profiles and dimensional accuracy.

Elimination of volatiles: The installation of a screen changer helps to eliminate water vapor and other volatiles from the raw material, which is particularly important for the production of certain profiles where the moisture content needs to be strictly controlled.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447