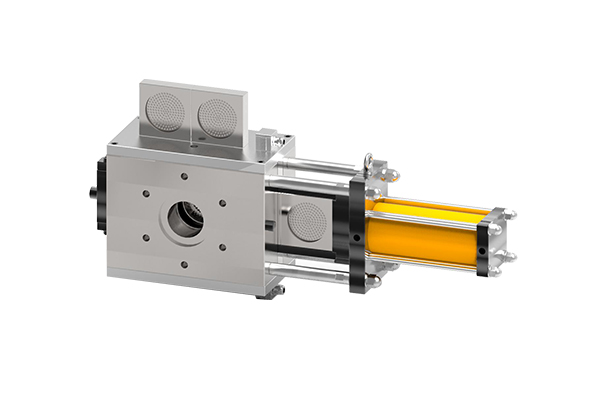

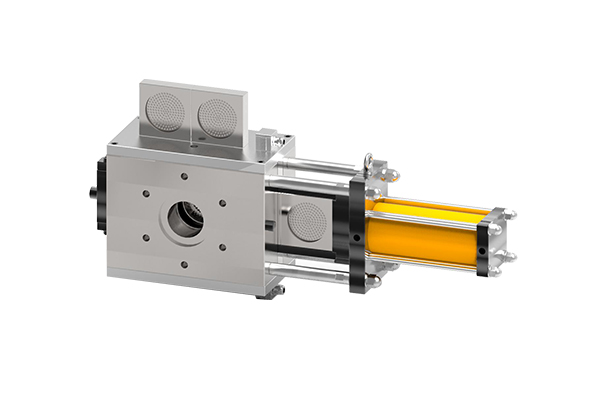

In the plastic pelletizing production process, the performance of the screen changer directly affects product quality and production efficiency. Single-plate hydraulic screen changer with its unique structural design, in the application of granulator shows significant advantages, become the preferred equipment for many enterprises.

First, compact and efficient, space-saving

Single-plate hydraulic screen changer has a compact structural design, compared with the double-plate or multi-plate screen changer, it only needs a slide plate to carry the filter, which greatly reduces the space occupied by the equipment. This feature is particularly important in the production of limited space in the workshop, can effectively save plant space, optimize the layout of the production line, and facilitate the installation and maintenance of equipment. At the same time, the simple single-plate structure reduces unnecessary parts and components, reduces the failure points of the equipment, makes the overall structure more stable and reliable, and runs with less vibration and noise, providing good protection for the production environment.

Second, fast screen changing, improve efficiency

Single plate hydraulic screen changer adopts hydraulic drive system, which can realize fast and accurate screen changing operation. When the filter mesh is clogged and needs to be replaced, the hydraulic system quickly drives the slide plate to move, and the spare filter mesh is quickly switched to the working position, and the whole mesh changing process can be completed within a few seconds, which greatly shortens the downtime. In the continuous production process of granulator, frequent screen changing operation will seriously affect the production progress and output if it takes too long, while the fast screen changing function of single-plate hydraulic screen changer can ensure the efficient operation of the production line, significantly improve the production efficiency and reduce the production cost.

Third, the melt flows smoothly, quality assurance

Its runner design has been optimized, usually with a streamlined structure, which enables the plastic melt to flow smoothly in the screen changer, no dead ends, no stagnant flow phenomenon. This design effectively reduces the residence time of the melt in the flow channel, reduces the risk of melt degradation, and ensures stable melt quality. At the same time, the single-plate structure makes the melt pressure distribution more uniform, with better filtration effect, which can effectively intercept the impurities and unplasticized particles in the plastic melt, and produce higher-quality plastic pellets to meet the stringent requirements of different customers for product quality.

Fourth, easy maintenance, reduce costs

The structure of the single-plate hydraulic screen changer is simple, the number of parts is relatively small, which makes the maintenance and repair of the equipment more convenient and quick. In routine maintenance, the operator can more easily check and replace the slide plate, filter, seals and other components. Moreover, due to the simplified structure, fewer maintenance parts are required accordingly, which reduces maintenance costs and the pressure on spare parts inventory. In addition, the simple structure also facilitates operators to quickly master the operation and maintenance methods of the equipment, reducing training costs and time.

Fifth. Reliable sealing to prevent leakage

In the structural design of the veneer hydraulic screen changer, the sealing component is the key part. The use of high-performance seals and reasonable sealing structure effectively prevents the plastic melt from leaking through the gap in the screen changer. Reliable sealing performance not only ensures the safety of the production process and avoids the waste of raw materials and environmental pollution caused by melt leakage, but also maintains the stable working pressure inside the screen changer to ensure the smooth operation of screen changing and the long-term stable operation of the equipment.

In summary, the granulator single plate hydraulic screen changer with compact and efficient, fast screen changing, smooth melt flow, easy maintenance and reliable sealing and other structural advantages, in the plastic pelletizing industry has an important application value, can enhance production efficiency for the enterprise to protect product quality, reduce production costs, help enterprises in the market competition to occupy an advantageous position.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447