The screen changer for silicone extruders is a critical piece of equipment in silicone extrusion production lines, primarily used to filter impurities and particles from molten silicone, ensuring product quality and production stability. Below is a detailed introduction to the screen changer for silicone extruders:

I. Functions

Filtering Impurities: During the silicone extrusion process, impurities and particles may be generated due to impure raw materials, additives, and mechanical wear. The presence of these impurities and particles can negatively impact product quality and performance. The screen changer intercepts these impurities and particles through a filter screen, ensuring the purity of the product.

Protecting Equipment: The filter screen also effectively prevents equipment wear and malfunctions caused by the presence of impurities and particles, thereby extending the service life of the equipment.

Improving Production Efficiency: The screen changer enables screen replacement without halting the machine or by reducing the extrusion speed during screen changes, minimizing production interruptions and enhancing production efficiency.

II. Types

Manual Screen Changer: Features a simple structure and low cost but requires manual operation for screen changes and necessitates a brief halt in the production line. It is suitable for small-scale pilot lines or low-volume production.

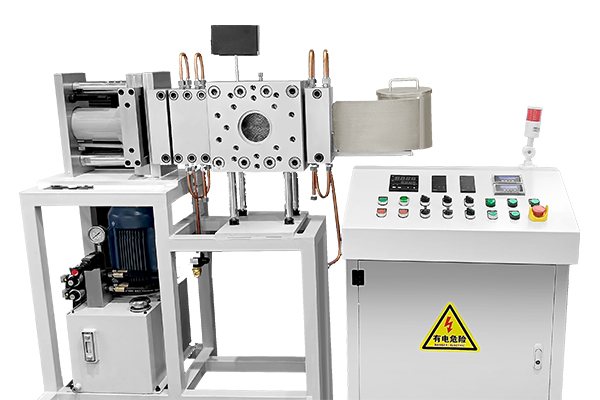

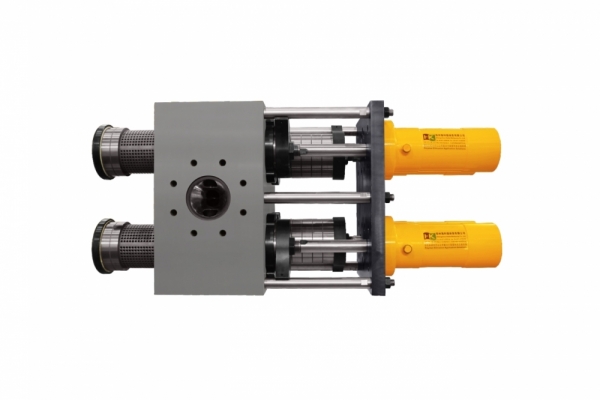

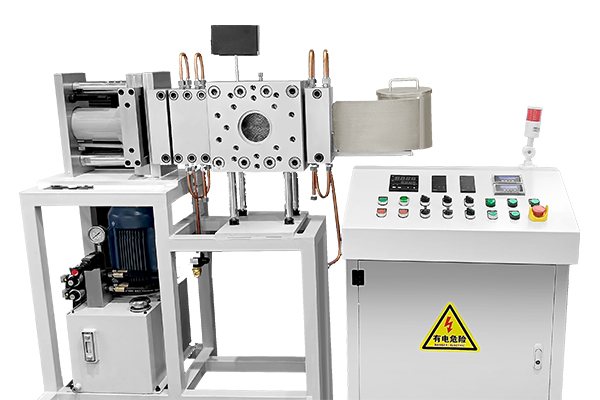

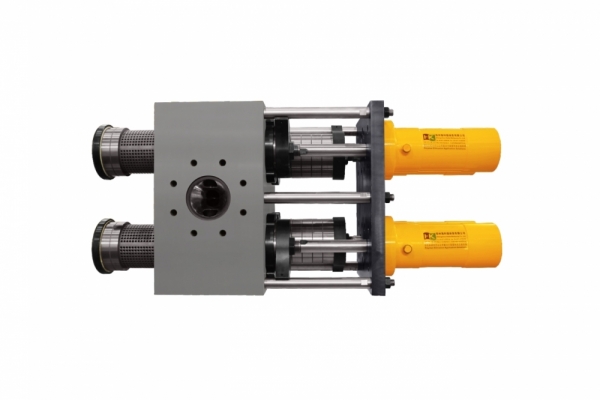

Hydraulic Screen Changer: Includes single-column and double-column hydraulic screen changers, which achieve automatic screen changes through a hydraulic system. The screen-changing process maintains relatively stable pressure and process conditions, making it suitable for large-scale continuous production.

Continuous Belt-Type Screen Changer: Utilizes a belt-type filter screen to achieve continuous filtration and screen changing, ideal for applications requiring high levels of continuous production.

Backflush Screen Changer: Features an online backflushing function that extends the lifespan of the filter screen and reduces the frequency of screen changes, making it suitable for high-contamination, high-output extrusion systems.

III. Selection Considerations

Material Characteristics: Choose an appropriate screen changer type and filter screen mesh size based on the viscosity, flowability, and other characteristics of the silicone.

Production Volume: Select the screen changer's specifications and model based on the production scale to ensure it meets production demands.

Automation Level: Choose a manual or automatic screen changer based on the automation level of the production line to improve production efficiency.

Cost Budget: Consider the cost budget of the screen changer while meeting production requirements to select a cost-effective product.

IV. Usage Precautions

Regularly Inspect and Replace Filter Screens: Ensure the normal operation of the equipment and product quality.

Pay Attention to Equipment Maintenance and Care: Such as regular cleaning and lubrication to extend the service life of the equipment.

Select an Appropriate Filter Screen Mesh Size: To balance filtration effectiveness and production efficiency.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447