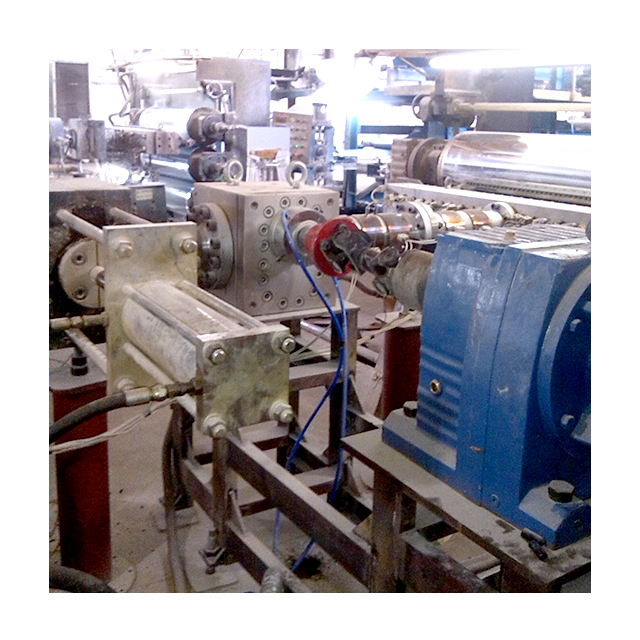

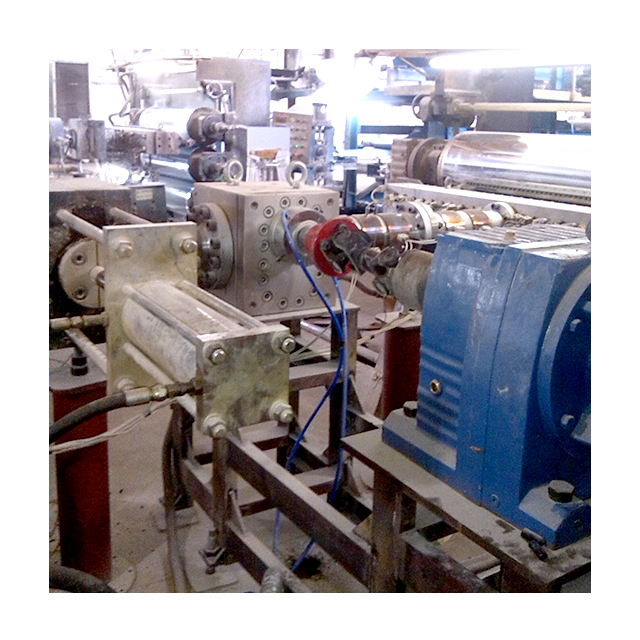

High-temperature melt gear pump is a key equipment for high-temperature polymer melt transfer and pressurization, the following is the introduction of its main parameters:

Flow rate

Definition: The volume of high temperature melt transported by the melt pump in a unit time, usually expressed in cubic meters / hour (m³/h), liters / hour (L / h) or cubic centimeters / second (cm³/s) and other units.

Influencing factors: mainly depends on the pump gear size, speed and viscosity of the melt and other factors. For example, at the same rotational speed, the larger the gear diameter, the larger the volume of melt transported per engagement, and the higher the flow rate; while for high viscosity melts, due to their poor fluidity, the actual flow rate may be relatively low under the same pump structure and rotational speed.

Pressure

Definition: The difference in pressure at the outlet of a melt pump relative to the inlet, reflecting the pump's ability to pressurize the melt, in megapascals (MPa) or bars (bar).

Importance: Sufficient pressure is essential to ensure that the high temperature melt can pass smoothly through the complex mold runners for precise molding. For example, in precision injection molding, a melt pump is required to provide a stable and high pressure to ensure that the plastic melt evenly fills all corners of the mold cavity, thus producing plastic products with high dimensional accuracy and good surface quality. Pressure requirements vary greatly from application to application, such as the production of small precision plastic parts may only require a few MPa of pressure, while large plastic products or some special industrial applications may require melt pumps to provide tens of MPa or even higher pressure.

Temperature

Definition: The temperature in degrees Celsius (°C) of the high temperature melt to which the melt pump is exposed during operation.

Effects and control requirements: The temperature of a high temperature melt has a significant effect on its viscosity and flow. Generally speaking, as the temperature rises, the melt viscosity decreases and the fluidity increases, but too high a temperature may lead to polymer degradation and affect product quality. Therefore, melt pumps need to have good high-temperature resistance, and in some applications, they also need to be equipped with a precise temperature control system to ensure that the temperature of the melt remains stable and appropriate throughout the conveying and molding process. For example, for the processing of some high-performance engineering plastics, temperature control accuracy of ±5°C may be required to ensure consistent product performance.

Rotation Speed

Definition: The speed of rotation of the gears in a melt pump, usually measured in revolutions per minute (rpm).

Relationship to Flow and Pressure: RPM is one of the most important factors affecting melt pump flow and pressure. Within a certain range, increasing the rotational speed can increase the flow rate of the melt pump, but at the same time it will also subject the melt to greater shear forces, which may affect the performance of the melt, and too high a speed may also lead to increased wear and tear of the pump and reduced stability of the equipment. In addition, the stability of the rotational speed is also very critical to ensure that the melt pump output flow and pressure stability, especially in the production process of high product quality requirements, usually need to be equipped with high-precision speed control device and speed feedback control system to ensure that the speed fluctuations are controlled within a very small range.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447