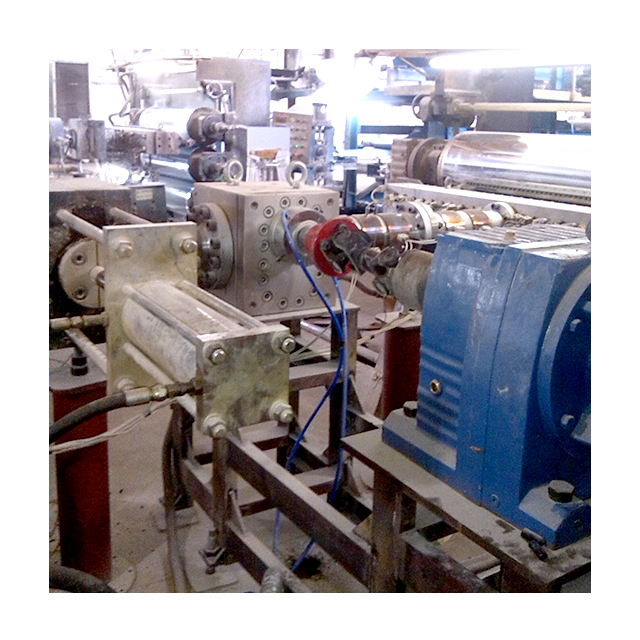

By stabilizing pressure and flow, improving melt quality and reducing extruder load, melt pump realizes precision extrusion of plastic sheet with thickness tolerance controlled at ±1% and energy consumption reduced by 15%~30%, which is the key equipment for production of high-end sheet such as optical-grade PET, medical-grade PVC and so on.

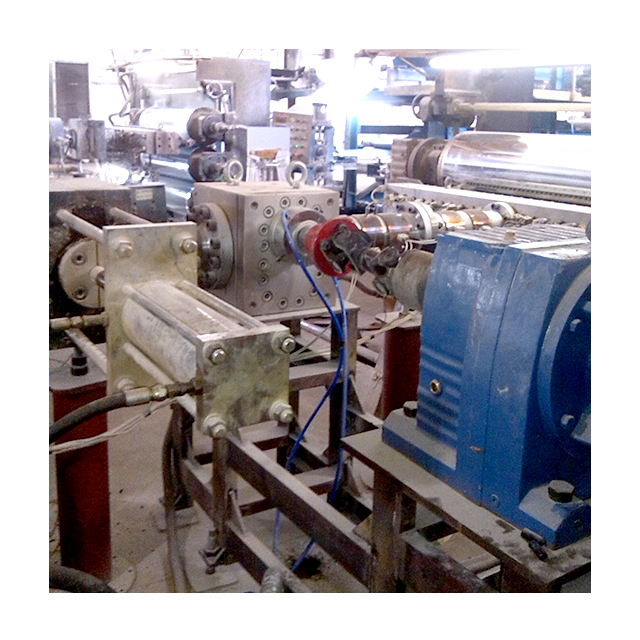

Plastic sheet precision extrusion process, melt pump with its unique technical advantages and role of the mechanism, become the key equipment to improve product quality and production efficiency. Its core advantages and role are reflected in the following aspects:

1, stabilize the melt pressure and flow to ensure precision extrusion

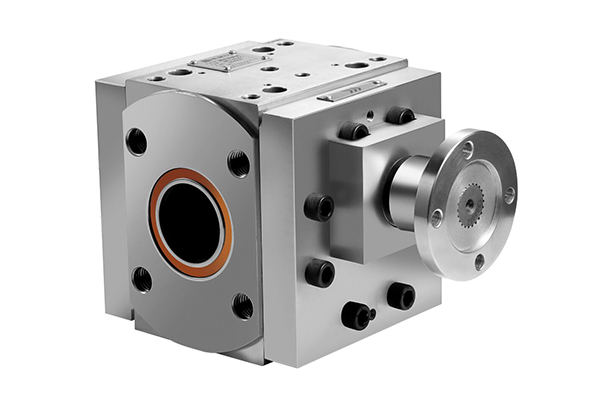

Pressure fluctuation suppression: melt pump through the gear meshing volumetric conveying principle, can buffer the extruder screw speed fluctuations, temperature changes and other factors caused by pressure pulsations, to ensure that the melt to a constant pressure into the die head.

Precise control of flow rate: The output flow rate of the melt pump is linearly related to the rotational speed, and the melt flow rate can be accurately controlled by adjusting the pump speed, which can meet the requirement of thickness uniformity of the sheet (the thickness tolerance can be controlled within ±1%), and significantly reduce the scrap rate.

Application Scenario: In the field of optical grade PET sheet, high barrier packaging film and other areas that require high thickness uniformity, the melt pump's stabilized pressure and flow characteristics can avoid flow marks on the surface of the sheet due to pressure fluctuations, uneven thickness and other problems.

2、Improve melt quality and optimize sheet properties

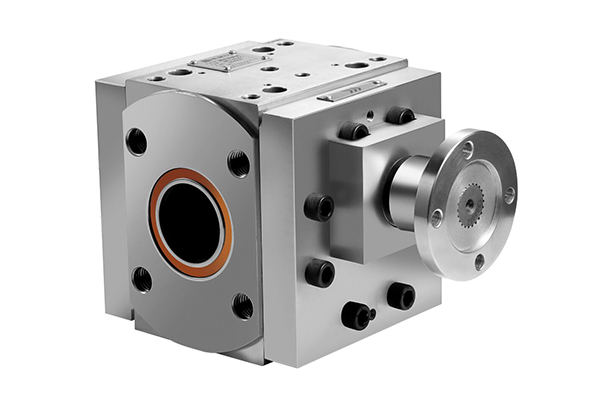

Melt homogenization: The shearing and mixing action of the internal gears of the melt pump can eliminate the “dead zone” residue in the melt, promote the dispersion of additives, reduce the defects of gel, crystal point, etc., and improve the surface finish and transparency of the sheet.

Thermal stability: By optimizing the runner design and heating system, the melt pump can accurately control the melt temperature (fluctuation range ≤±1℃), avoiding fluctuations in sheet properties (e.g., inconsistent shrinkage, decreased mechanical properties) caused by uneven temperatures.

Typical example: In the production of medical grade PVC sheet, the homogenization function of the melt pump ensures uniform distribution of the plasticizer, avoiding brittleness or segregation of the sheet due to local differences in plasticizer concentration.

3、Reduce the load of extruder and prolong the life of equipment.

Pressure reducing and stabilizing function: melt pump undertakes the task of pressure building at the end of the extruder, so that the extruder screw can run under lower pressure, reducing the wear and tear of the screw and barrel and prolonging the service life of the equipment.

Optimization of energy consumption: The high efficiency of the melt pump can reduce the load on the extruder motor, reducing the overall energy consumption by 15% to 30%, while reducing the risk of melt degradation due to high temperature and high pressure.

Process stability: By reducing the extruder back pressure, the melt pump reduces the melt retention time in the barrel and avoids performance degradation caused by the long thermal history of the material, which is especially suitable for the processing of heat-sensitive materials (e.g. PC, PMMA).

4、Broaden the process window to meet diversified needs

High-viscosity material processing: melt pump can provide up to 40MPa output pressure, easy to transport high-viscosity melt (such as PEEK, LCP and other engineering plastics), breaking through the viscosity limitations of traditional extruders.

Multi-layer co-extrusion compatibility: In multi-layer co-extruded sheet production, melt pumps can independently control the flow and pressure of each layer of melt to ensure precise inter-layer bonding strength and thickness ratios to meet the needs of high-performance composites.

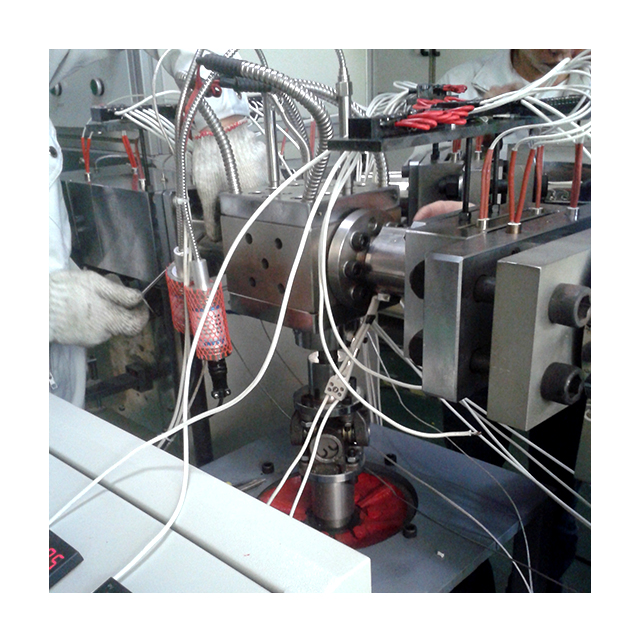

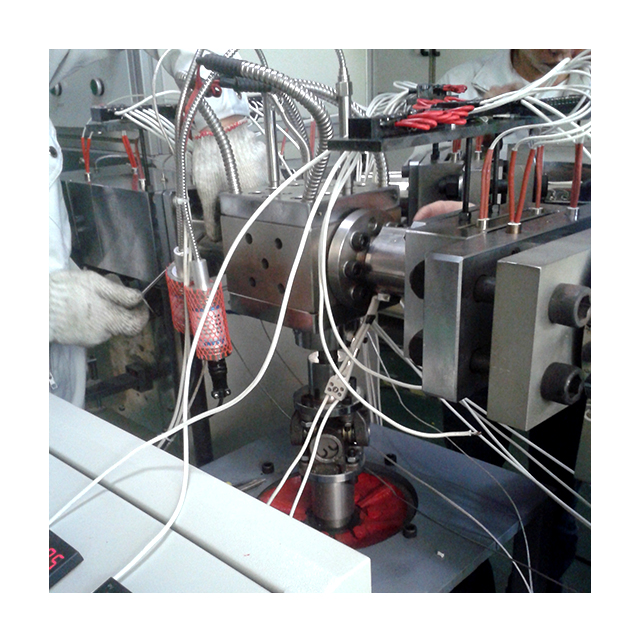

Special process support: the melt pump can be linked with online thickness gauge and closed-loop control system to realize real-time feedback and adjustment of sheet thickness, which is suitable for high-end processes such as microfoam sheet and high barrier coating.

5、Modular design, flexible integration and maintenance

Compact structure: the melt pump adopts short flow channel and low shear design with compact size, which can be easily integrated into the existing extrusion line without large-scale modification.

Easy maintenance: modular gear set and seal structure facilitates quick disassembly and replacement, reducing downtime for maintenance; some high-end models support online cleaning (CIP) function, further improving production efficiency.

Extended functions: optional heating/cooling jacket, pressure sensor and other accessories can be equipped to realize the whole process monitoring and data tracing of melt temperature, pressure and flow rate.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447