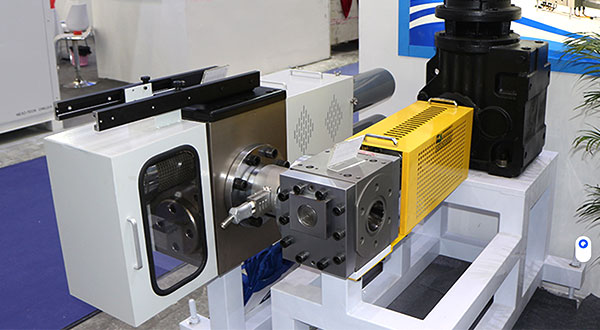

The core value of adding screen changers to extrusion systems lies in simultaneously enhancing production efficiency and product quality, making them a critical configuration for ensuring stable and efficient extrusion operations. Specific reasons are as follows:

1. Precise Impurity Filtration: Screen changers efficiently intercept various contaminants in materials, including aged resin particles and non-plastic impurities in recycled feedstock (such as metal shavings and fibrous contaminants). This prevents product defects caused by impurities at the source—for instance, eliminating pinholes and sand holes in plastic pipes, avoiding fiber bundle breakage due to contaminants, and ensuring the integrity of product appearance and structure.

2. Ensuring Quality Stability: By utilizing screens of varying precision, the screen changer flexibly adapts to diverse product specifications, maintaining material purity consistently within production standards. This effectively prevents quality deviations caused by fluctuations in material cleanliness, supporting standardized production.

3. Enhancing Production Continuity: The screen changer supports non-stop screen changes, significantly reducing downtime associated with traditional screen-changing processes. It is particularly suitable for scenarios demanding high production continuity, such as long auxiliary forming lines and multi-branch extrusion, substantially minimizing production losses and boosting overall efficiency.

4. Optimized Material Plasticization: The screen changer's structural design increases die backpressure, promoting thorough plasticization and uniform mixing of materials within the barrel. This reduces localized defects caused by insufficient plasticization, further enhancing product density and surface finish.

5. Extended mold service life: Clean, filtered material substantially reduces abrasion and wear on mold runners and cavities caused by impurities. This decreases mold maintenance frequency and repair costs, prolonging mold service life and indirectly lowering production expenses.

6. Improved Material Rheological Behavior: Screen changers guide material flow from rotational to linear motion, effectively preventing flow defects like “twist marks” on product surfaces. They also optimize flow velocity distribution at the die exit, adjust product strength distribution, and enhance the uniformity of mechanical properties.

In summary, the screen changer plays a multifaceted role through impurity filtration, quality assurance, and continuous production support. It not only enhances the efficiency and stability of extrusion production but also solidifies the foundation of product quality, establishing itself as an indispensable core auxiliary component in modern extrusion production systems.