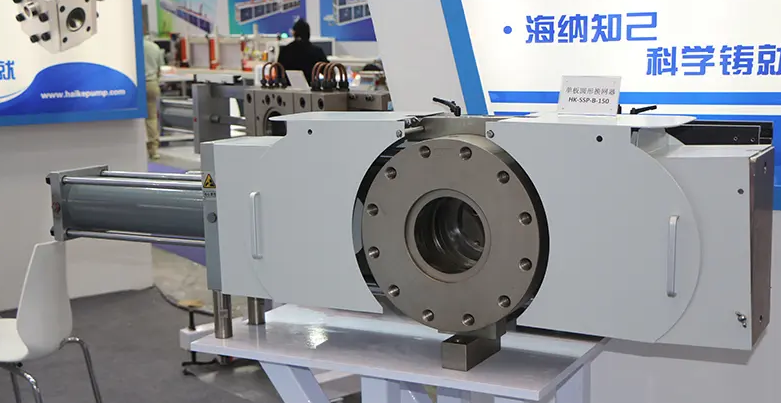

A single-plate hydraulic screen changer typically refers to a single-plate quick-change hydraulic screen changer, a melt filtration device widely used in continuous production fields such as plastic extrusion and polymer chemistry.

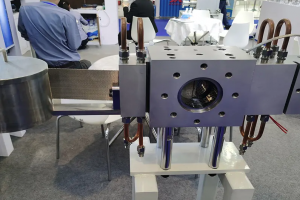

Structural Components:

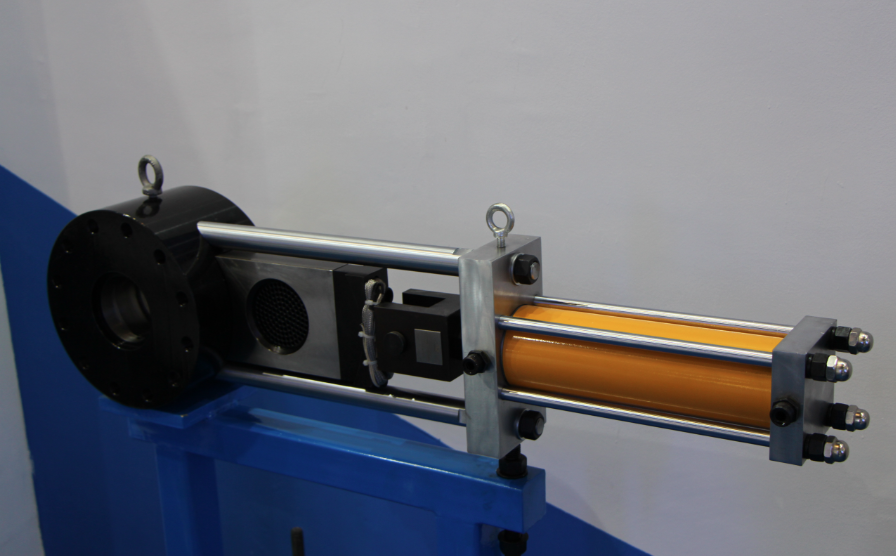

Slide Plate and Filter Channels: The slide plate features two filter channels, each fitted with a removable perforated plate (screen). One station operates while the other serves as a backup.

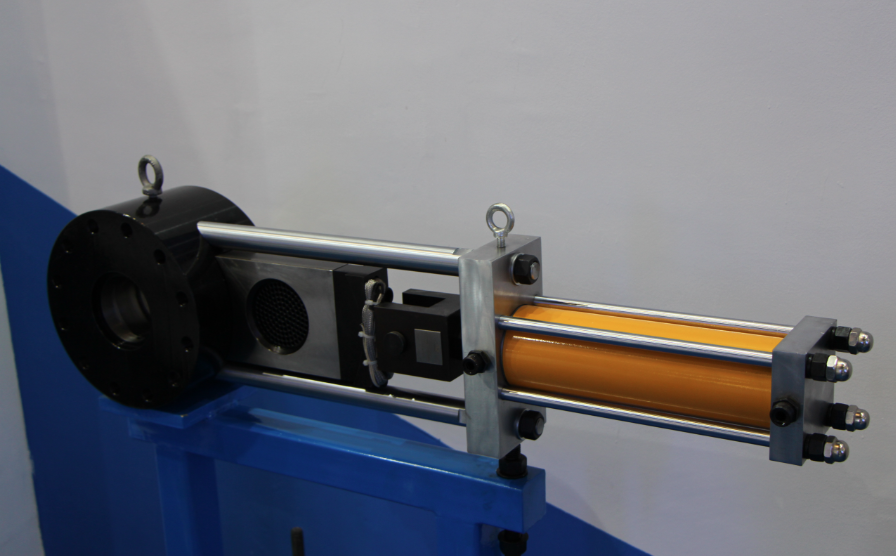

Hydraulic Drive System: Comprising hydraulic cylinders that reciprocate the slide plate to switch positions.

Sealing and Compensation Mechanism: Typically employs pressure-driven rigid sealing technology with self-compensating clearance to prevent material leakage.

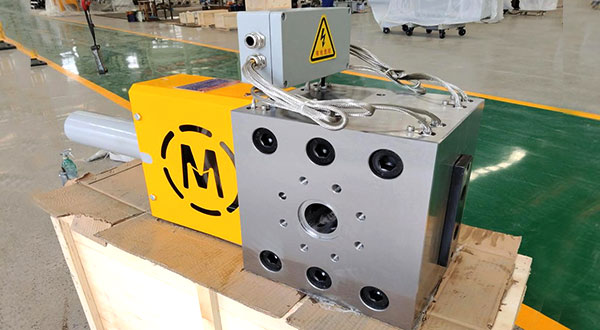

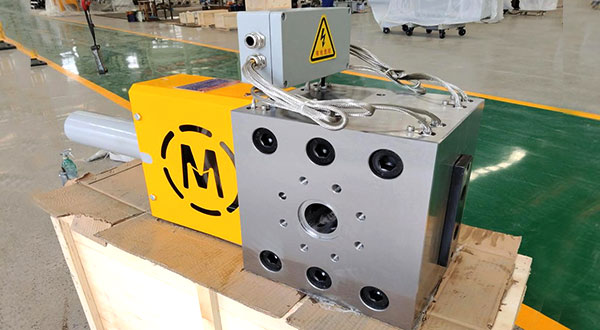

Heating and Insulation System: Equipped with electric or thermal fluid heating to maintain stable filter zone temperatures, preventing melt solidification or degradation.

Working Principle: During normal production, molten material passes through the working station's filter screen, where impurities are intercepted. Purified material flows to subsequent die heads. When pressure increases due to impurity buildup on the working filter, the hydraulic system activates. Hydraulic fluid drives the slide plate to move, bringing the clean spare filter into operation while the dirty filter retracts to the change position. This enables filter replacement without stopping production, maintaining uninterrupted material flow.

Core Features and Advantages:

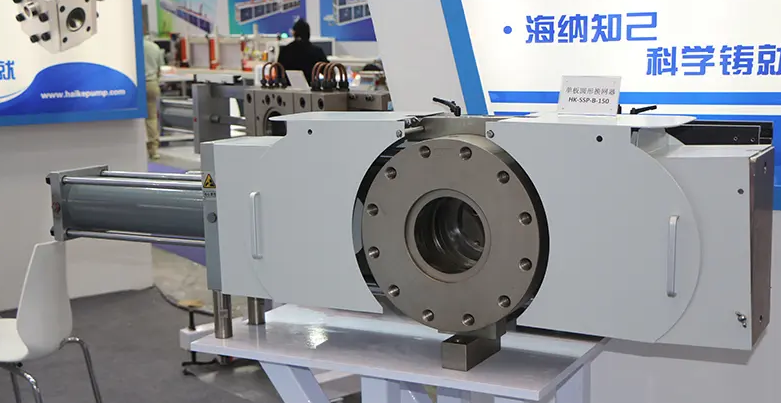

Simple Structure, Easy Integration: Utilizes a plate-type design with direct, unobstructed flow channels. Easily connects to single-screw extruders, twin-screw extruders, or reactors of various specifications, simplifying production line layout and material flow paths.

High cost-effectiveness, broad applicability: Its relatively simple structure offers manufacturing cost advantages while meeting filtration demands for polymerization production ranging from general-purpose plastics to diverse polymeric chemical raw materials.

Non-stop screen change, continuous production: Hydraulic system-driven rapid screen switching within 2-5 seconds effectively ensures production continuity and stability, enhancing efficiency.

Reliable Sealing, Zero Material Leakage: Features a pressure-activated sealing mechanism. When melt pressure builds, the seal automatically compresses under pressure and self-compensates, ensuring tight sealing even under high-pressure conditions.

Optimized Flow Path, Material Protection: The flow path is rheologically optimized and equipped with a porous support plate. This effectively reduces shear stress and pressure loss during melt passage, making it suitable for shear-sensitive or high-viscosity materials.

Primary Applications: Widely used in plastic extrusion molding for melt filtration in production lines such as sheet, plate, pipe, profile, blown film, cast film, and wire/cable sheathing. Also employed in pelletizing and compounding processes like masterbatch, functional masterbatch, and modified plastic pelletizing via strand pelletizing or underwater pelletizing. Additionally applicable in chemical fiber and resin polymerization fields.