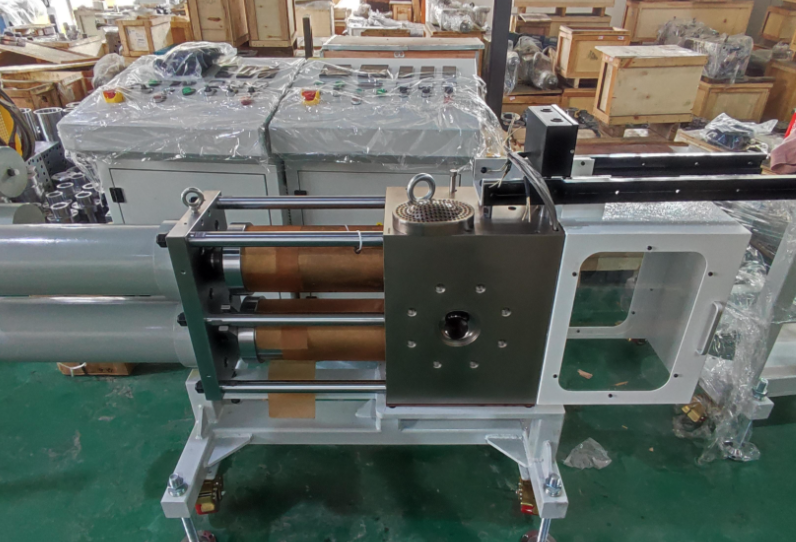

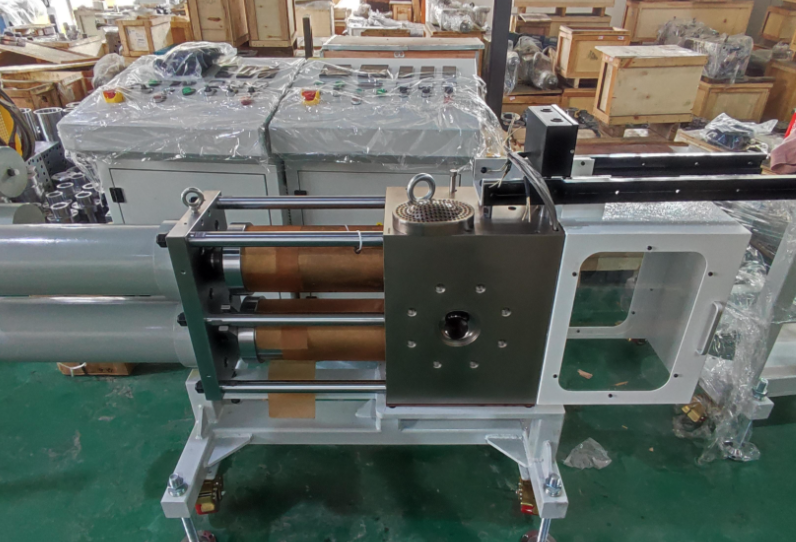

The screen changer for underwater granulators serves as a core component in plastic granulation production lines. Primarily designed to filter melt impurities and enable non-stop screen changes, it ensures continuous production and product quality. Key information is summarized below:

I. Core Structure and Working Principle

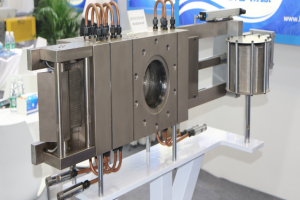

Dual-column, dual-station design

Features dual-column, dual-station filtration channels. During screen changes, one station switches while the other continues filtering, preventing material flow interruption. The hydraulic system drives column position switching, working with perforated plates to intercept impurities.

Progressive Venting and Flow Path Optimization

Gas is expelled from the melt via dedicated venting structures, preventing bubbles from contaminating the final product. Channel design minimizes material stagnation, reducing degradation risks.

II. Core Advantages

Continuous Production: Alternating operation during screen changes enables non-stop screen replacement, ideal for high-precision processes like underwater pelletizing.

High-Efficiency Filtration: Dual-channel design increases filtration area, enhancing impurity removal efficiency.

III. Typical Application Scenarios

Plastic Recycling Pelletizing: Achieves deep filtration through dual screen changes (pre-melting/post-melting) when processing contaminated raw materials.

High-End Polymer Processing: Suited for underwater pelletizing lines of TPU, TPE, and other materials requiring high sealing integrity and stability.