The single-plate screen changer has become an indispensable piece of equipment in extrusion production due to its multidimensional advantages. Its core value is reflected in five key aspects:

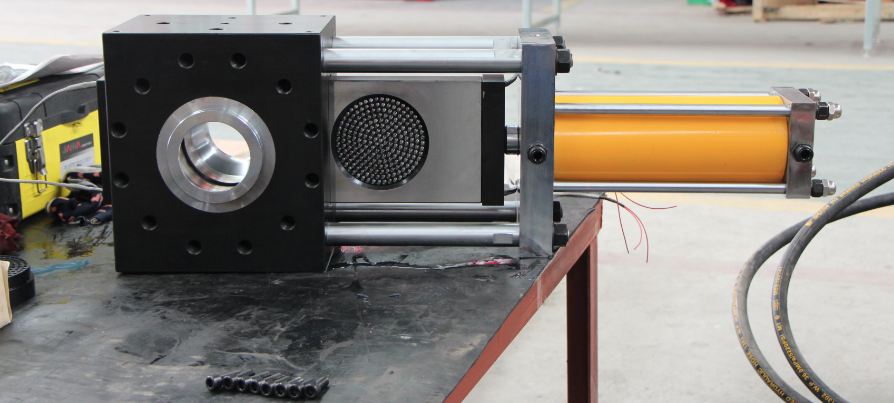

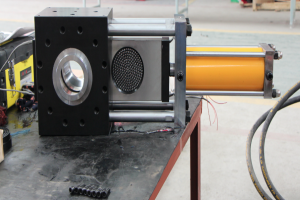

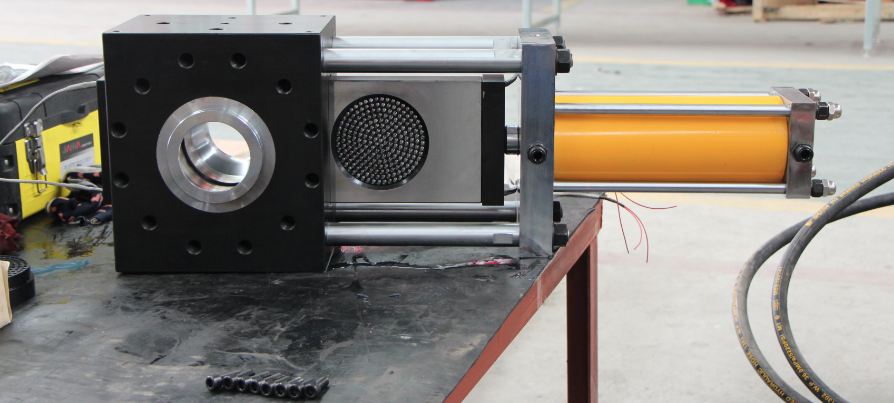

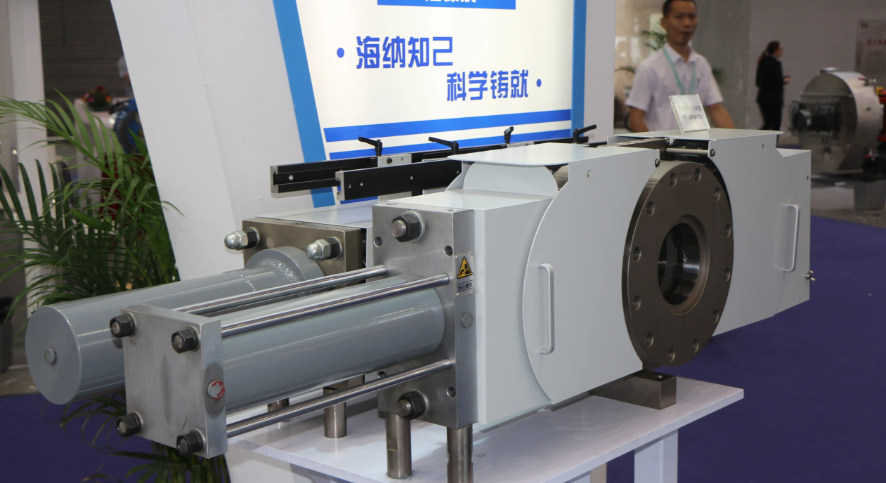

High screen-changing efficiency stands out as a significant highlight. Equipped with a hydraulic drive system, it completes screen changes rapidly within 2-5 seconds without requiring production stoppage. This effectively prevents production interruptions and significantly boosts overall efficiency, making it particularly well-suited for continuous extrusion requirements.

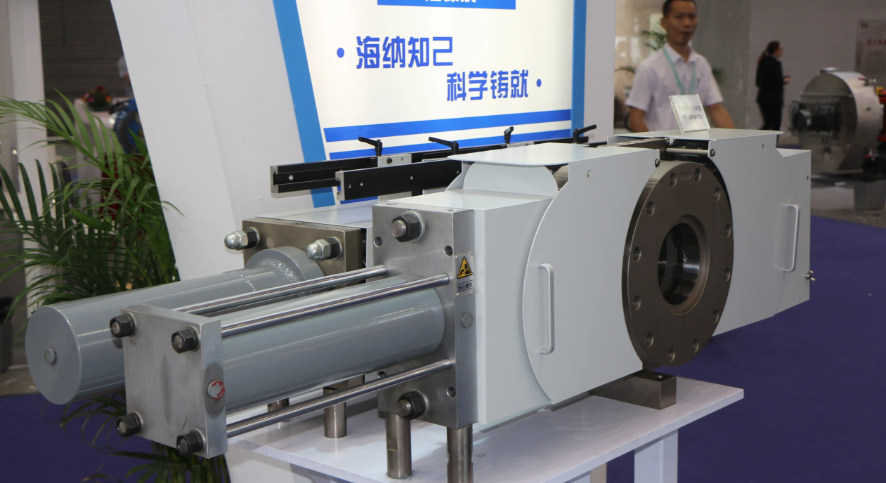

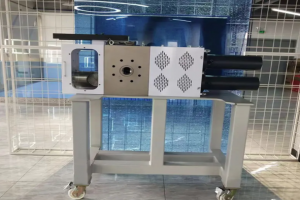

Compact structural design with a sliding-plate layout substantially reduces equipment footprint. It offers flexible installation even in small-scale production lines, laboratory setups, or space-constrained workshop layouts, ensuring superior adaptability.

Reliable sealing performance, leveraging pressure-driven sealing technology, consistently adapts to high-output extrusion scenarios. It effectively eliminates material leakage, safeguards production stability, and minimizes material waste and equipment contamination.

It offers broad applicability, directly interfacing with various extrusion dies without requiring major production line modifications. Compatible with multiple material categories including plastics, rubber, and synthetic fibers, it reduces equipment adaptation costs.

Maintenance costs are economical, with straightforward operation procedures that staff can master after brief training. The equipment features extended maintenance intervals and low routine upkeep expenses, minimizing operational investment during production.