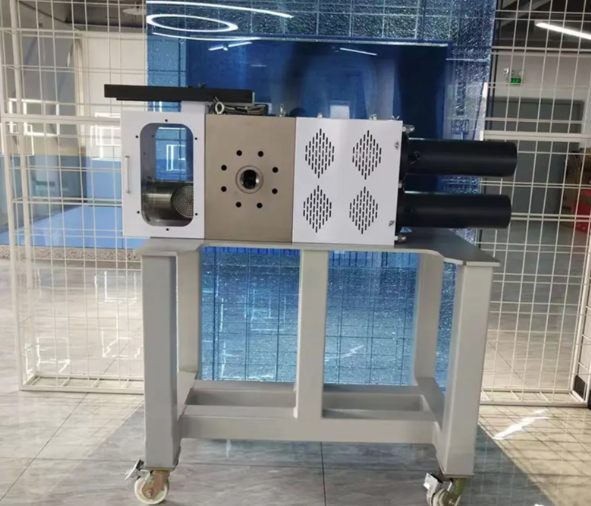

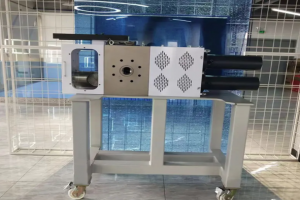

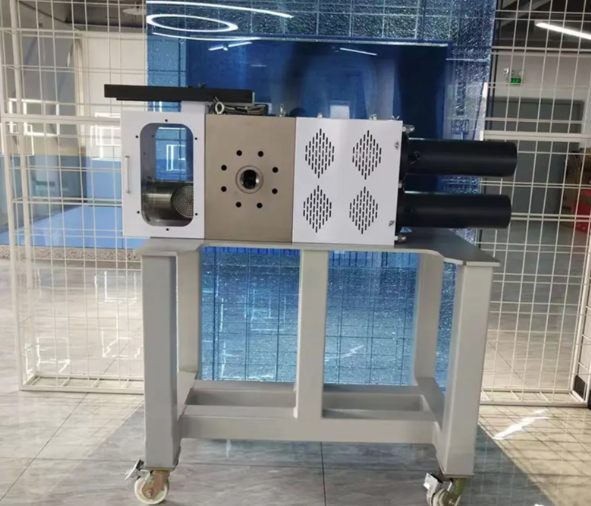

Non-Stop Screen Changes Ensure Continuous Production

Featuring a dual-piston, dual-channel design, the dual-piston screen changer enables simultaneous operation of two filter screens. When one screen requires replacement, the other continues running, allowing screen changes without production downtime. This ensures uninterrupted production and minimizes material waste.

High-Efficiency Filtration and Product Quality Assurance

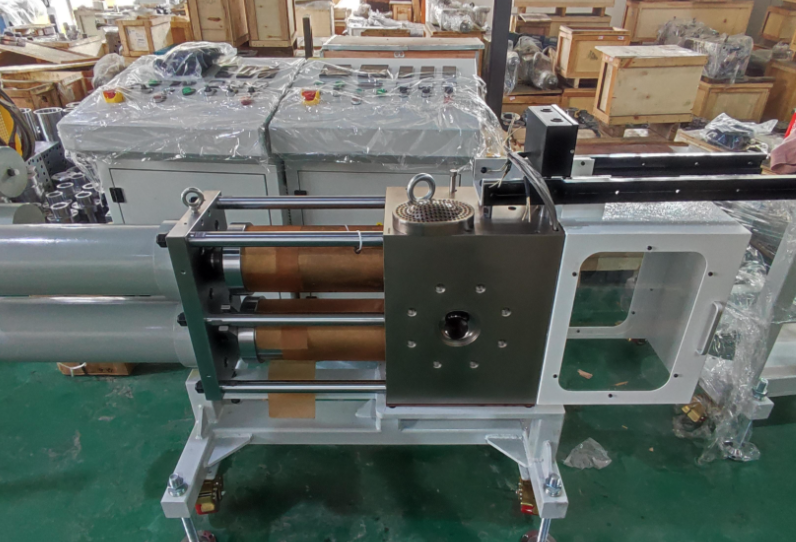

Increased Filtration Area: Curved or large-area screen designs (e.g., dual-column four-station versions) significantly expand filtration area compared to traditional single-screen changers, effectively handling high-viscosity materials and fillers (e.g., glass fiber, calcium carbonate).

Product Quality Assurance: Progressive material feeding and venting structures prevent gas entrapment, ensuring uniform product quality.

Extended Production Cycles & Reduced Maintenance Costs

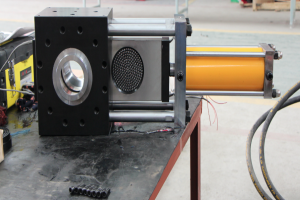

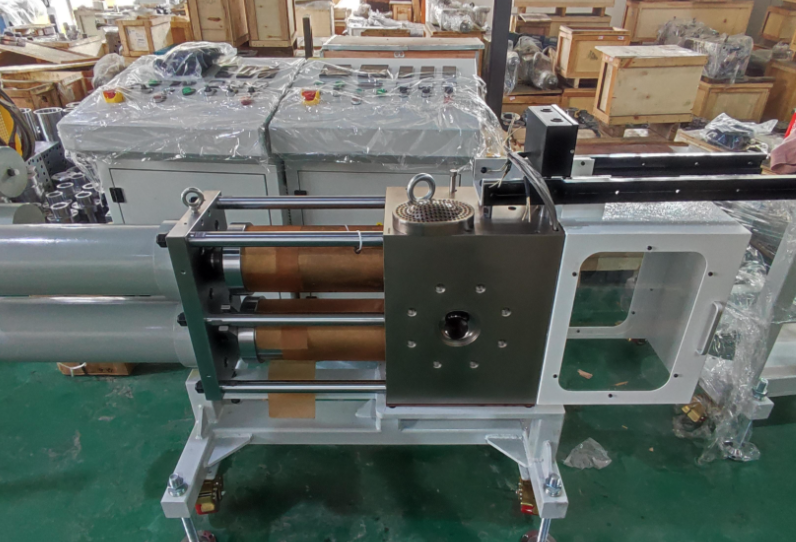

Wear-Resistant & Corrosion-Resistant Materials: Premium alloy steel body (nitrided) combined with rigid sealing design ensures leak-free operation under high pressure and temperature (≤400°C, ≤35MPa), significantly extending equipment lifespan.

Reduced Screen Change Frequency: Large-area screens extend single filtration cycles, lowering screen change frequency by 30%-50% while saving on screen consumables and labor maintenance time.

Enhanced Product Quality and Adaptability

Optimized flow channel design: Minimizes material retention and degradation risks. Removable orifice plate structure facilitates cleaning of cold material.

Flexible filtration precision: Supports rapid switching between 20-300 mesh screens, accommodating diverse requirements from coarse impurity removal to optical-grade precision filtration.