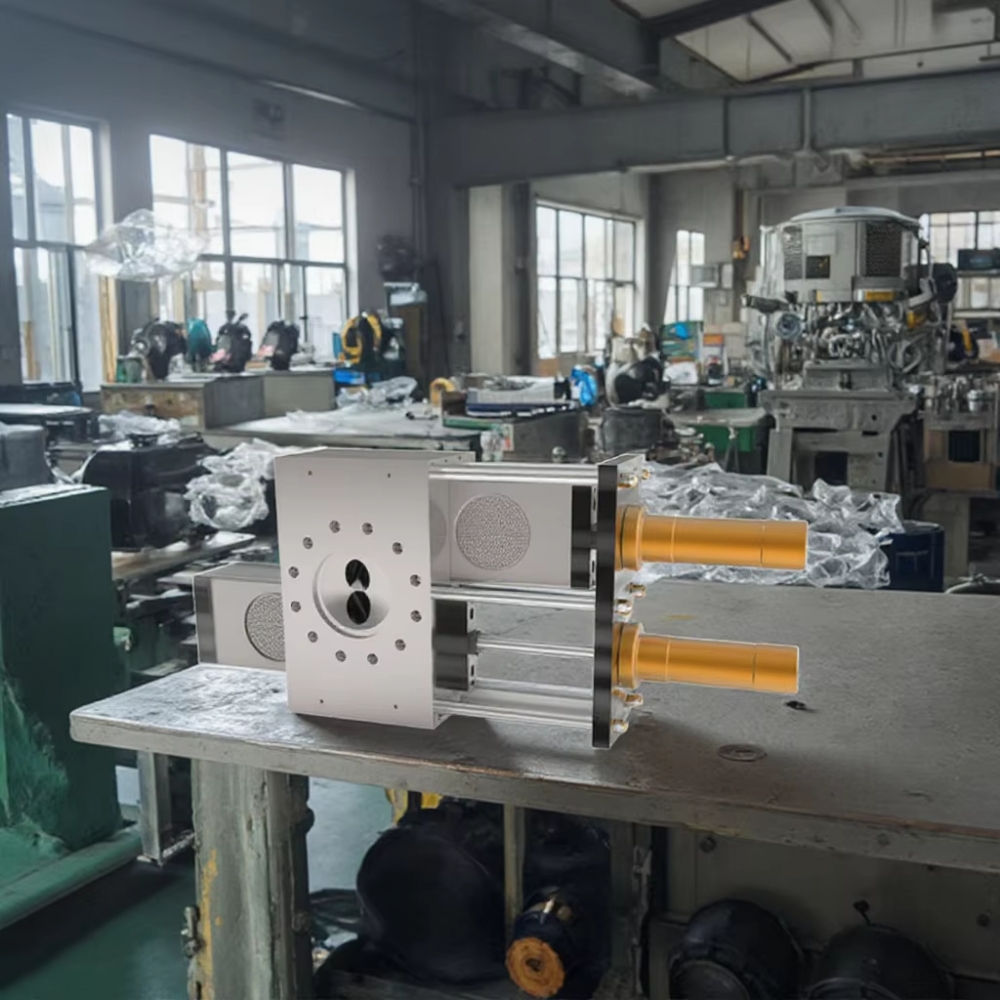

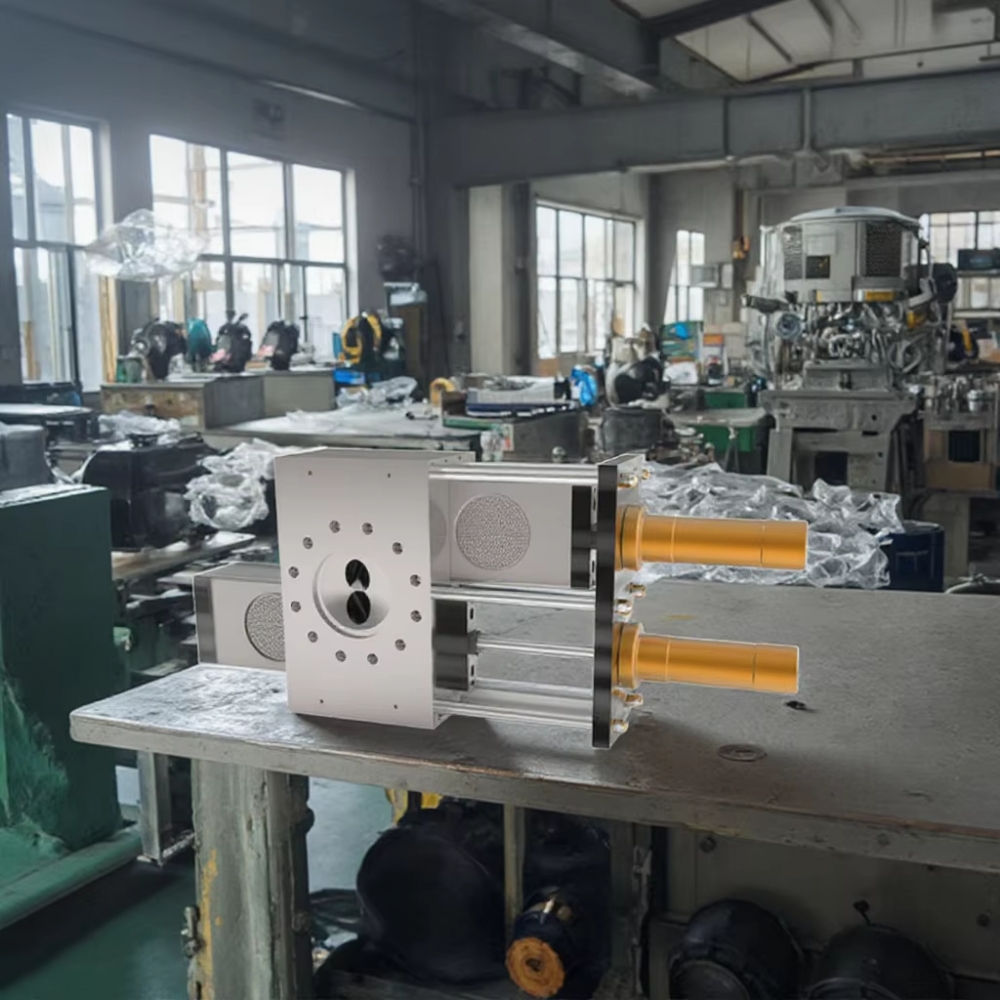

The dual-plate, dual-station non-stop screen changer is a highly efficient, continuous auxiliary device for plastic extrusion production. Featuring a dual-plate, dual-channel design, it enables rapid screen changes without production downtime, ensuring continuous and high-efficiency manufacturing.

Key Features of the Dual-Plate, Dual-Station Non-Stop Screen Changer

Dual-Station Design: One screen operates while the other stands by, eliminating downtime during changes and significantly boosting production efficiency.

High-Precision Hydraulic Control: Utilizes a high-precision hydraulic control system to execute precise screen changes, ensuring product quality and stability.

Excellent Sealing Performance: Features a reliable sealing structure that effectively prevents material leakage, avoiding production environment contamination and material waste.

Easy Operation and Maintenance: Simple and convenient operation with screen changes performed via the hydraulic station; compact structure facilitates routine maintenance and servicing.

Versatile Heating Methods: Supports various heating options including heating rods and heating plates based on production requirements.

High Adaptability: Widely applicable for use with various production equipment such as pelletizers, film blowers, pipe extruders, sheet extruders, and plate extruders.

The dual-plate, dual-station non-stop screen changer is particularly suited for high-efficiency plastic extrusion lines, such as those producing pellets, blown film, pipes, sheets, and films. It effectively boosts production efficiency, ensures product quality, and reduces manufacturing costs.

<svg class="" focusable="false" aria-hidden="true" viewbox="0 0 24 24" data-testid="ImageSearchIcon"></svg>