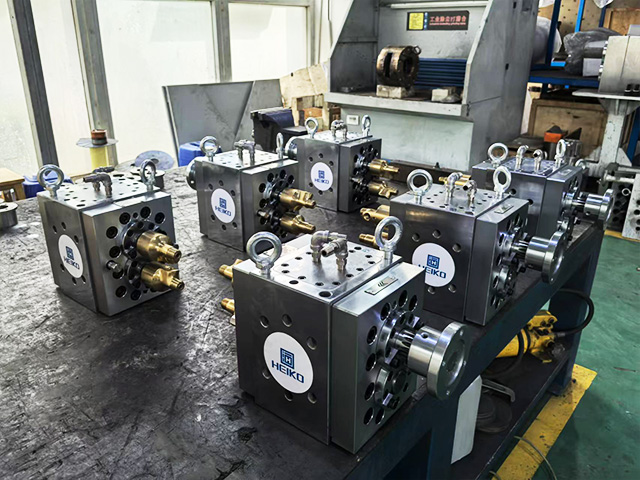

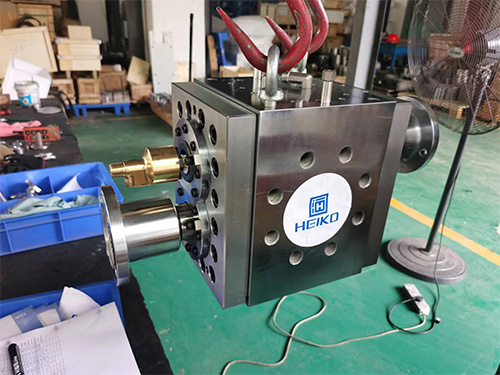

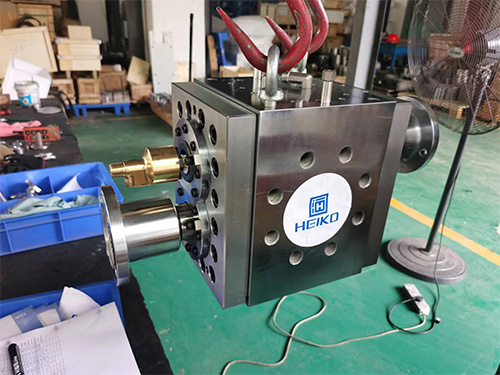

The melt pump for EVA optical films is a high-temperature melt delivery device specifically engineered for EVA resin. Through precise gear meshing and flow channel design, it achieves efficient and stable melt transportation, significantly enhancing the production quality and efficiency of optical films.

Core Function: Pressure Stabilization and Metering

The melt pump eliminates pressure fluctuations (within ±1%) from the extruder, ensuring the melt enters the die head at constant pressure and stable flow rate. Its flow rate is strictly proportional to rotational speed, allowing precise melt flow control (flow range: 0.5-15,000 cc/rev) by adjusting speed to meet production demands for optical films of varying thicknesses.

Application Advantages: Enhanced Film Quality and Production Efficiency

Improved Film Dimensional Accuracy

By eliminating extruder pressure fluctuations, the melt pump significantly enhances film thickness uniformity (±0.3% flow accuracy), reducing scrap rates. This is particularly advantageous for high-precision optical film production.

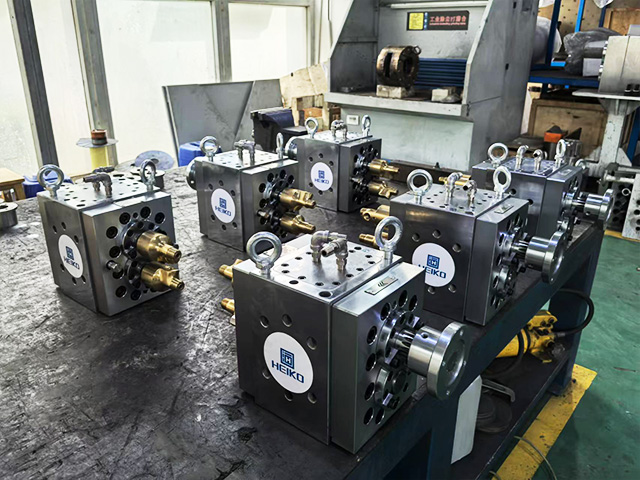

Reduced Energy Consumption and Extended Equipment Lifespan

Low-Temperature Extrusion: The extruder operates at lower pressure and temperature, minimizing leakage flow and increasing output.

Reduced Back Pressure: The melt pump handles pressure boosting, lowering extruder back pressure and reducing axial forces on the screw, thereby extending equipment lifespan.

Energy Savings: Energy consumption per kilogram of processed material can be reduced by approximately 25%.

Adaptability to Multiple Materials and Applications

Material Compatibility: Beyond EVA, it can be used for the extrusion molding of polymers such as PS, PP, and PET.

Application Flexibility:

Multi-machine Feeding: Multiple small-to-medium extruders simultaneously feed a single melt pump to produce large-scale products (e.g., large-diameter pipes, wide-width films).

Direct Extrusion: Installing a melt pump on a single-screw or twin-screw pelletizing extruder eliminates the pelletizing step, enabling direct product extrusion and streamlining the process flow.

Application Value in High-End Fields

In demanding applications like medical catheters and optical films requiring stringent dimensional tolerances, the melt pump ensures flow accuracy within ±0.3%, meeting the production demands of high-end products.