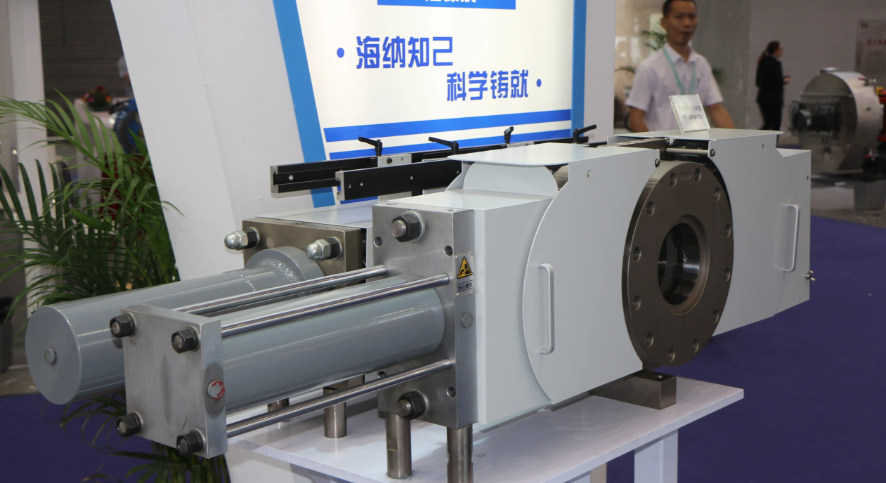

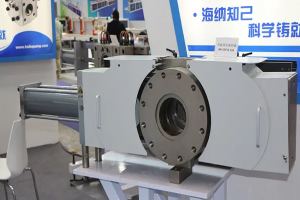

Plastic and rubber extrusion operators are surely familiar with the single-plate hydraulic screen changer! Its rapid screen changes and compact size stem entirely from its ingenious structural design. Today, we dissect its core structural features—understand why it's so effective after reading!

Four Core Structural Features

Single-plate filter design for streamlined screen changes

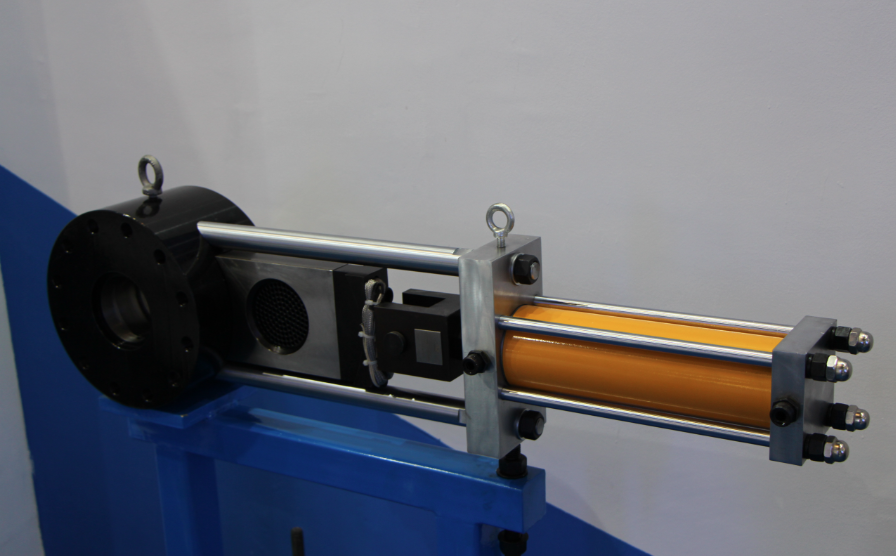

The core is a single sliding plate with an integrated filter! Unlike dual-plate machines that switch between two plates, it fixes the filter directly onto a single sliding plate. This makes the structure more compact and smaller in size, requiring minimal installation space and easily adapting to small production lines.

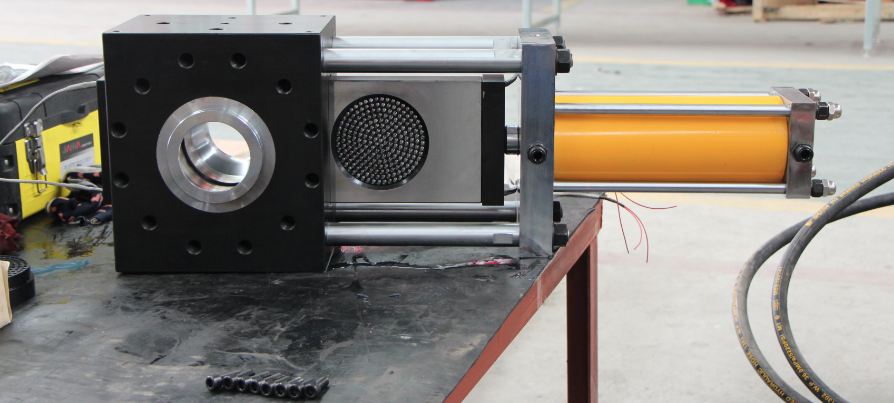

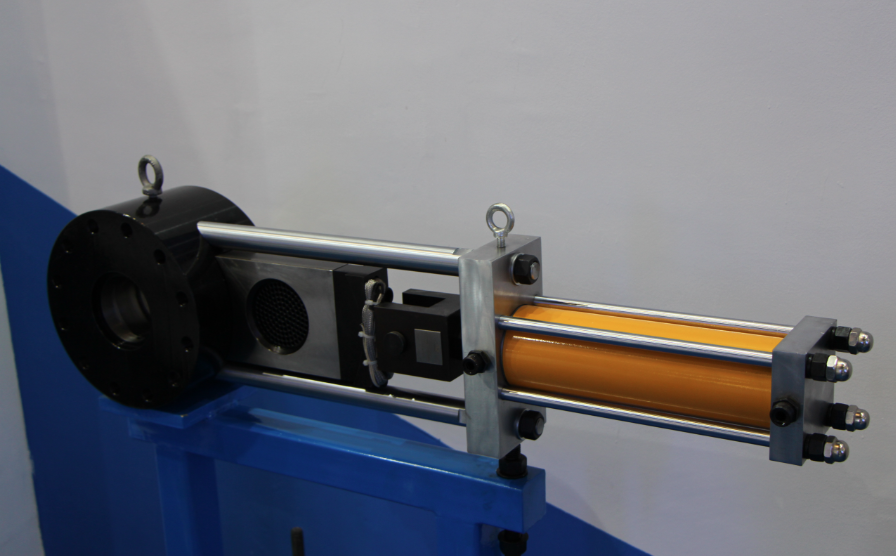

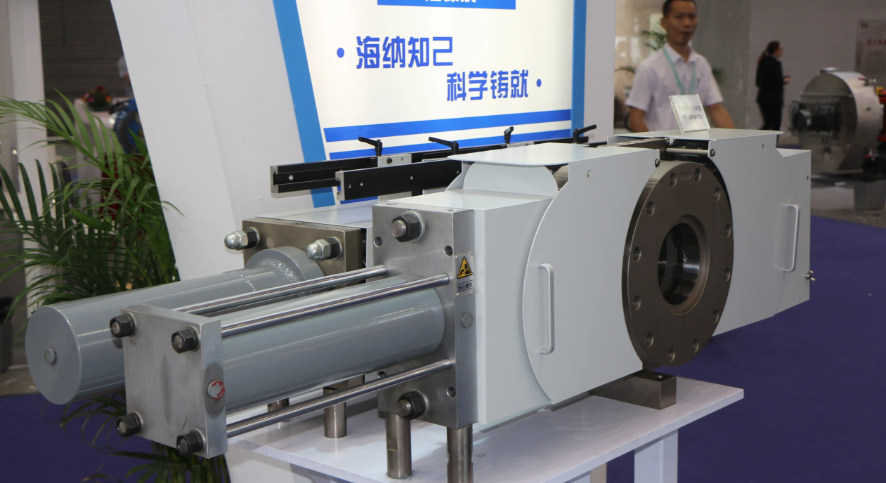

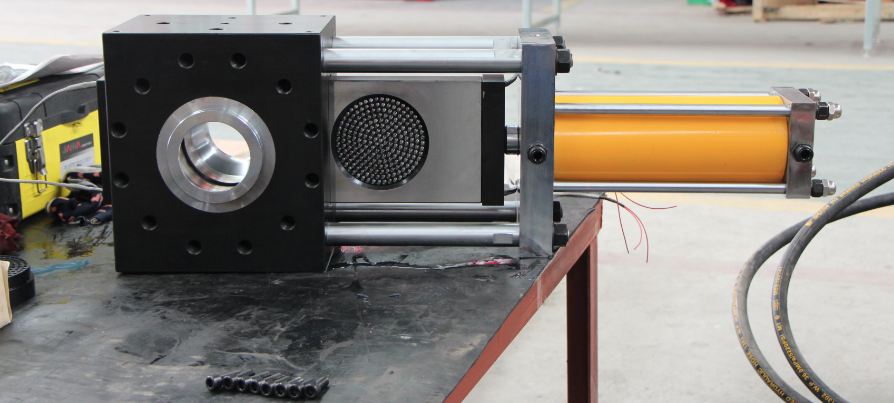

Hydraulic Drive System: Smooth and Swift Switching

A hydraulic cylinder propels the slide plate! Compared to manual screen changes, hydraulic power delivers uniform force, ensuring smooth, stutter-free movement. Screen changes complete within 3 seconds, with precise speed control via hydraulic valves preventing material leakage from screen displacement.

Precision-machined sealing surfaces ensure leak prevention

The pump body and slide plate sealing surfaces undergo mirror polishing, paired with high-temperature resistant seals for exceptional fit. Even when conveying high-temperature, high-viscosity melts (e.g., PE, PVC), it maintains a tight seal with virtually no melt leakage, ensuring a cleaner production environment.

Short, smooth flow paths minimize melt resistance

Internal flow channels are designed to be compact and streamlined, eliminating unnecessary bends! Melt experiences minimal resistance from entry to exit, preventing stagnation or degradation caused by complex pathways. This makes it ideal for extrusion applications demanding high melt quality, ensuring consistent product performance.

Why do established factories love it?

Simple structure means easy maintenance! No complex disassembly is required when changing screens—just open the cover plate to replace the screen on the slide plate, making it accessible even for beginners. Plus, it costs less than dual-plate screen changers, offering exceptional value for small to medium-batch production.

Whether for pipe extrusion, film production, or pelletizing, it's the perfect fit!