I. Core Functions and Value

Stabilizing Extrusion Pressure and Flow Rate

The melt pump utilizes fixed-volume chambers formed by gear meshing to perform secondary pressurization and stabilization of the melt output from the extruder. This eliminates pressure pulsations caused by rotational speed fluctuations and temperature variations in upstream equipment (such as the screw), controlling outlet pressure fluctuations within ±1%. This significantly enhances sheet thickness uniformity.

Enhanced Product Precision and Yield Rate

In applications demanding stringent thickness tolerances—such as optical-grade sheets (e.g., light guides) and high-barrier films—the melt pump reduces tolerances from ±5% to ±1%, minimizing scrap rates. For instance, one enterprise achieved a ±1μm thickness fluctuation for BOPP film (down from ±3μm) and a 12% yield rate increase by installing a melt pump.

Reduced Energy Consumption and Extended Equipment Lifespan

Melt pumps transfer the pressure reduction function from the extruder to themselves, enabling the screw to operate at lower pressure and temperature (typically reduced by 20-30°C). This minimizes melt degradation and leakage flow while reducing axial forces on the screw, thereby extending the lifespan of bearings and seals. Test data indicates energy consumption can be reduced by 15%-25%.

II. Technical Parameters and Selection Guidelines

Key Parameters

Flow Range: 0.5CC to 12000CC, matched to extruder output (typically selected at 80%-120% of extruder flow rate).

Pressure Range: Outlet pressure ≤40MPa, suitable for high-pressure applications like multi-layer co-extrusion and high-filler sheets.

Temperature Range: Melt temperature ≤400℃, cleaning temperature ≤450℃, compatible with conventional plastics (PE, PP, PET, PC) and engineering plastics.

Viscosity Adaptability: Supports up to 40,000Pa·s, covering materials from low-viscosity PE to high-viscosity PA66.

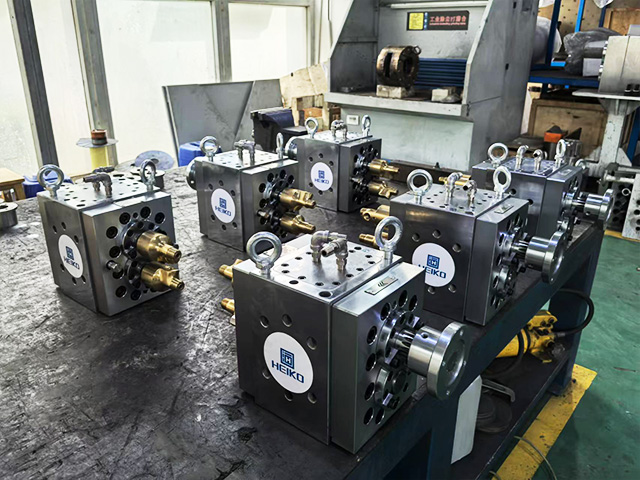

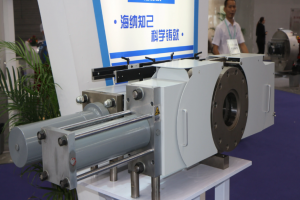

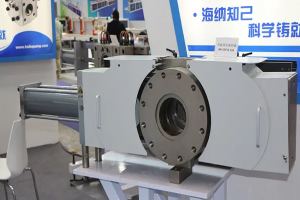

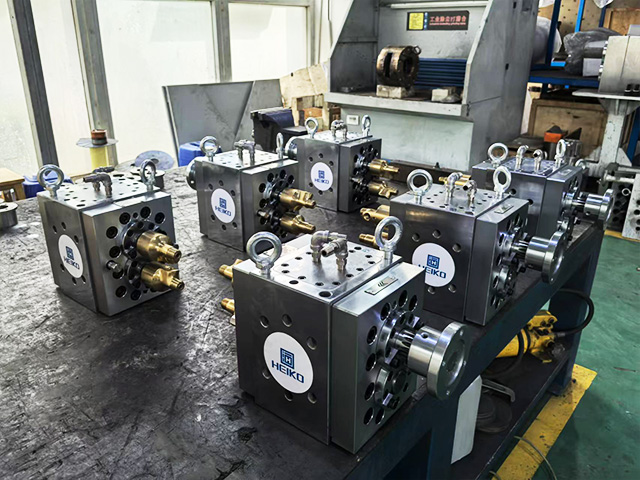

Structure and Materials

Gear Types: Spur, helical, or herringbone gears. Helical and herringbone gears offer smoother meshing, making them suitable for high-pressure and high-speed applications.

Material Selection: Pump body made of alloy steel (e.g., 38CrMoAlA), gear shafts using nitrided tool steel with surface hardness ≥HRC60, delivering three times the wear resistance.

Sealing Design: Packing seals or mechanical seals. Packing seals suit high-temperature conditions, while mechanical seals offer lower leakage rates (≤0.5mL/h).

III. Typical Application Scenarios

Optical-Grade Sheet Production

In manufacturing PMMA light guides and PC diffusion sheets, melt pumps eliminate pressure fluctuations to prevent flow marks and crystallization defects caused by unstable melt flow, thereby enhancing light transmittance.

High-Barrier Film Coextrusion

In coextrusion processes combining high-barrier layers (EVOH, PVDC) with PE/PP, melt pumps precisely control layer flow ratios to ensure uniform barrier layer thickness, extending food packaging shelf life.

Wood-Plastic Composite Sheets

In manufacturing wood-plastic sheets like PVC+wood flour or PE+rice husk composites, melt pumps stabilize extrusion pressure to prevent density variations caused by wood flour settling. This enhances sheet bending strength and water resistance.