In continuous production processes such as plastic extrusion and chemical fiber spinning, traditional screen changers require shutdowns for filter replacement. This not only impacts production efficiency but also leads to raw material waste and product quality fluctuations. Achieving non-stop continuous filtration has become an urgent challenge for many enterprises.

Working Principle

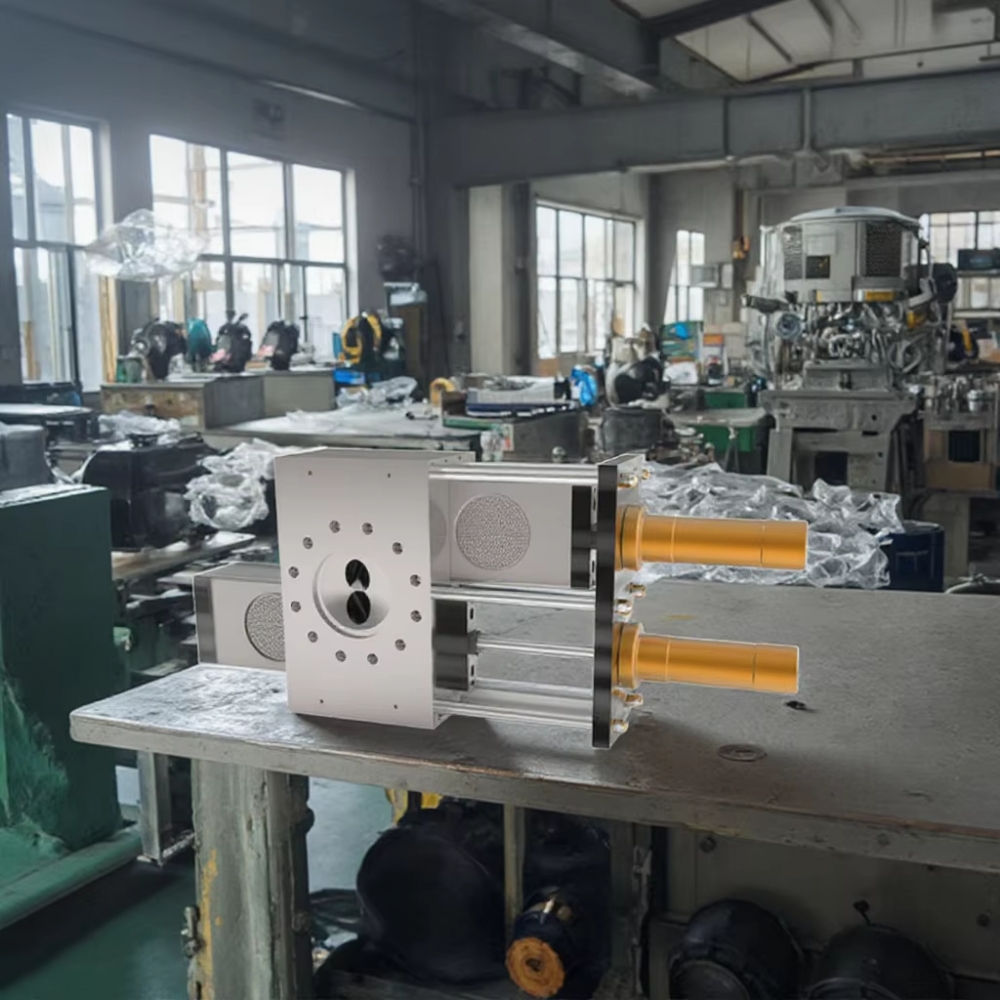

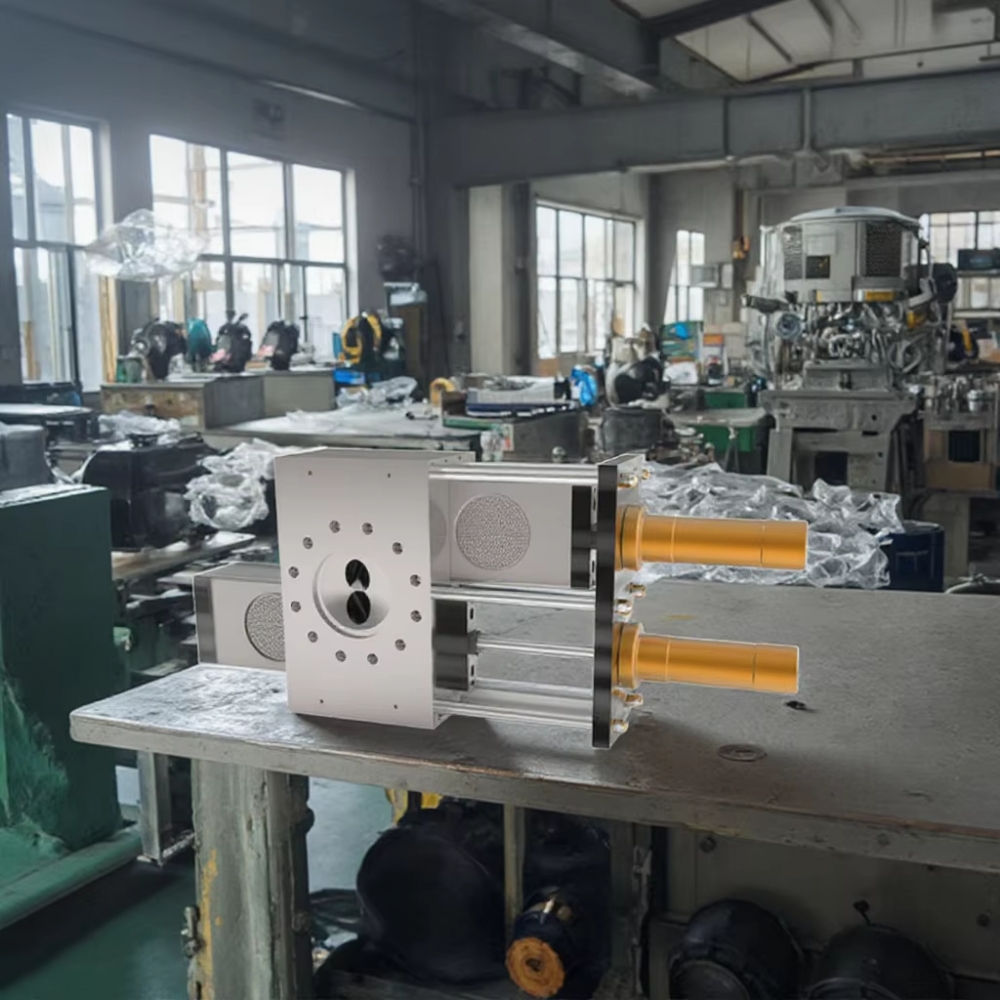

Utilizes an alternating dual-plate filtration mode

When one filter plate becomes clogged, the hydraulic system automatically switches to the standby plate

Enables replacement and cleaning of clogged filter plates without production stoppage

Core Advantages

Enhanced Production Efficiency: Eliminates frequent shutdowns to maintain continuous operation

Reduced Material Loss: Minimizes waste generated during screen changes

Consistent Product Quality: Sustained filtration pressure ensures product uniformity

Simplified Operation: High automation reduces labor intensity

Selection Criteria

Select appropriate mesh size based on material properties

Consider maximum operating pressure and temperature range

Evaluate hydraulic system response speed and stability

Verify compatibility with existing production lines

By adopting continuous plate-type screen changers, enterprises not only eliminate production interruptions but also significantly enhance product quality and economic efficiency. Selecting the appropriate model and performing routine maintenance will transform this equipment into an indispensable “filtering guardian” on your production line.