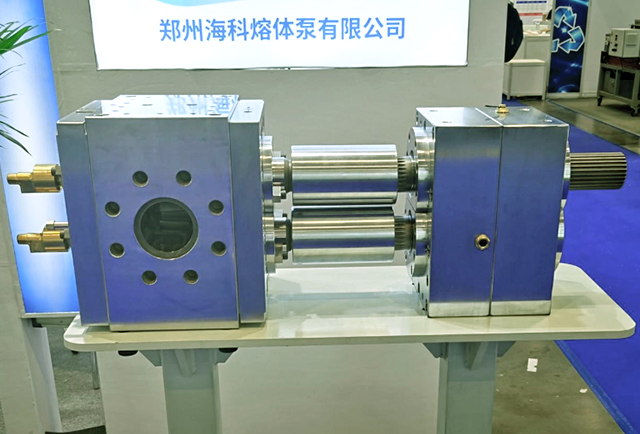

As a core piece of equipment in the field of polymer processing, rubber extrusion melt pumps are used in a wide range of industrial applications, particularly in the processing of rubber and high-viscosity materials, where they offer unmatched technical advantages.

1. Tire Manufacturing

Tread rubber extrusion: The use of involute gear design prevents carbon black filler deposition and avoids pre-crosslinking before vulcanization. For example, after a well-known tire company retrofitted its downstream system with a melt pump, the dimensional tolerance of tread rubber decreased from ±1.2mm to ±0.3mm, and the annual scrap rate dropped by 23%.

Sidewall rubber and triangle rubber production: Stable delivery of high-viscosity rubber ensures uniformity and improves tire dynamic performance.

2. Rubber Seals and Vibration Damping Products

Seal strip extrusion: In the production of automotive door and window seal strips, the melt pump achieves near-linear flow output, enabling seal strip cross-sectional dimensional accuracy of ±0.1 mm, meeting the stringent standards of the automotive industry.

Vibration damping rubber components: By eliminating extrusion fluctuations through pressure stabilization, the fatigue resistance of the components is enhanced, extending their service life.

3. Silicone rubber and specialty rubber processing

Silicone rubber molding: Using corrosion-resistant materials such as duplex stainless steel to resist fluorine-containing additive corrosion, equipment lifespan is extended by over three times.

Fluororubber and acrylate rubber: Stable conveying under high-temperature (350°C) and high-pressure (40 MPa) conditions to prevent material thermal degradation.

4. Rubber mixing and preforming

Downstream systems of internal mixers: Stabilize fluctuations in rubber compound viscosity, improve mixing uniformity, and provide stable raw materials for subsequent extrusion.

Rubber preforming: Precisely measure rubber compound volume, reduce excess material in subsequent processing, and minimize material waste.

Rubber extrusion melt pumps have expanded beyond traditional rubber processing into multiple fields such as plastics, food, pharmaceuticals, and new energy. Their core technology lies in addressing high-viscosity material processing challenges through high-precision, high-stability conveying.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447