As a key equipment in modern plastics processing industry, automatic screen changer plays an important role in the production of high-quality and long-flow products. It is widely used in cast film, film manufacturing, as well as a variety of wire drawing, granulation and other production processes, highly suitable for high-level automated production lines for the melt of the stringent requirements of efficient filtration.

First. Basic structure and sealing method.

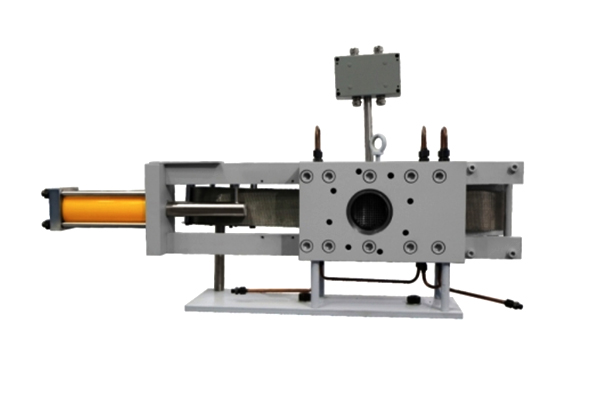

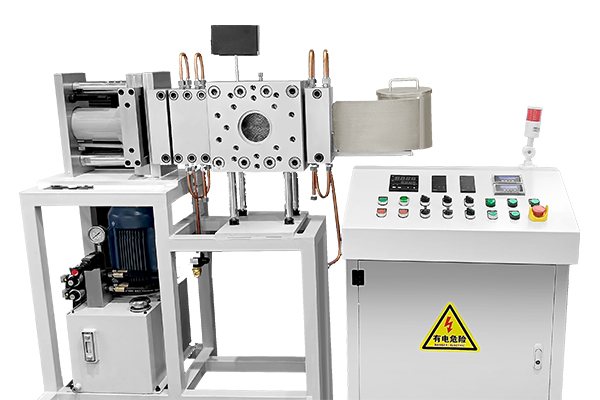

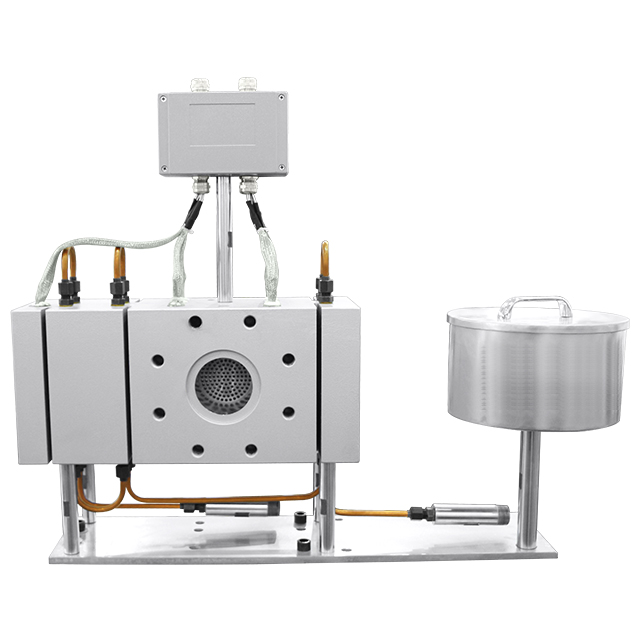

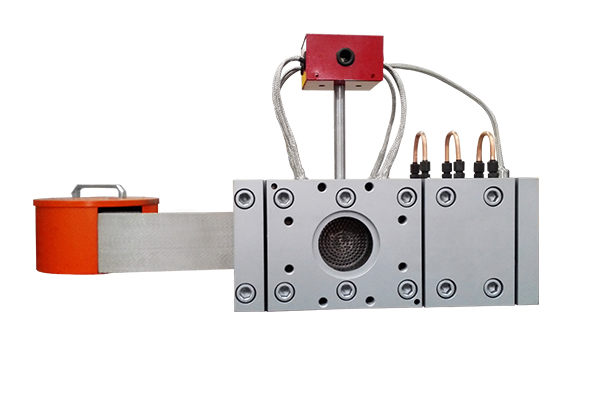

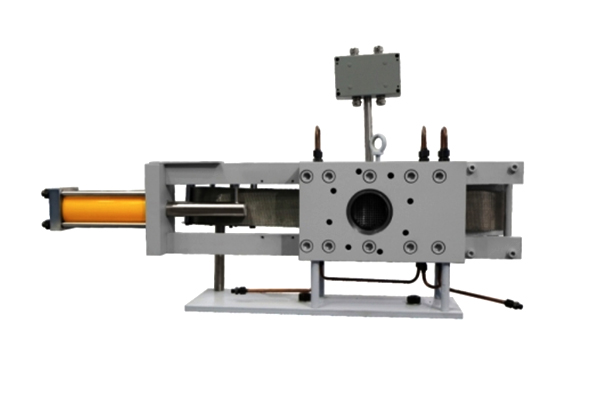

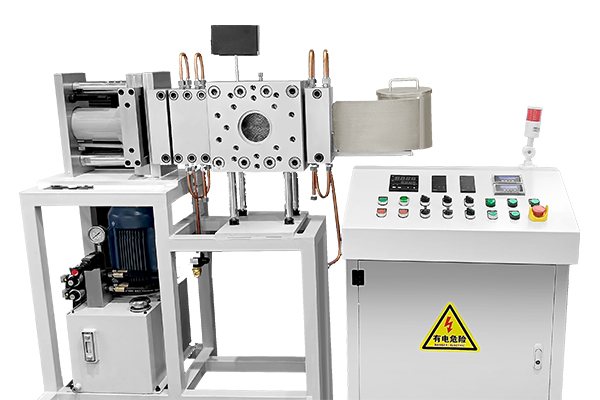

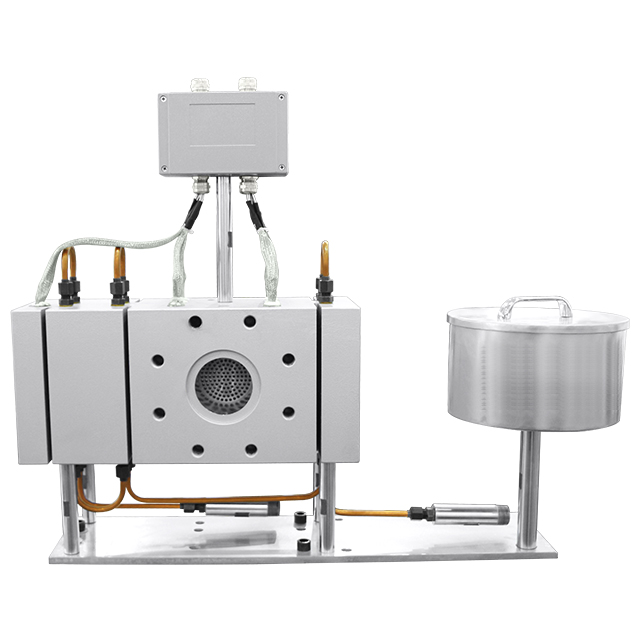

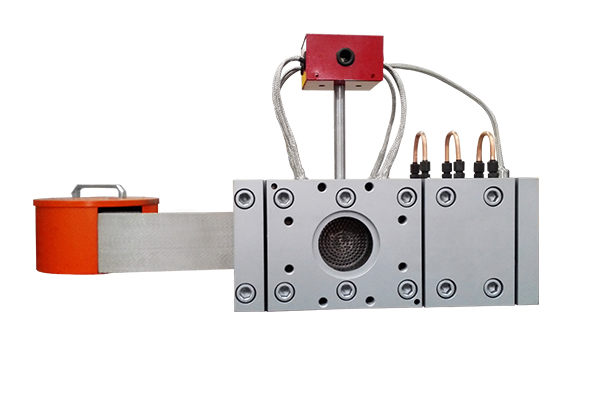

Structural composition: the mesh belt automatic screen changer is mainly composed of mesh belt, filter box, inlet cooling section, main runner connection section, outlet cooling section and electric control system.

Water-cooled sealing: Water-cooled sealing is adopted to ensure that the melt will not leak during the working process. This sealing method can effectively prevent the leakage of high-temperature melt, ensure the safety and stability of production, and also reduce the waste of raw materials and pollution of the environment.

Second, the trigger mechanism of walking net action.

Melt pressure trigger: In the production process, when the melt pressure in the feed port of the screen changer reaches the pre-set value, it will trigger the screen walking action. As production proceeds, the impurities in the melt will gradually accumulate at the filter net, leading to a rise in the pressure at the feed port. When the pressure reaches the set value, the control system will automatically start the subsequent screen walking program.

Time-controlled triggering: In addition to the melt pressure trigger, it is also possible to control the screen walking action according to a pre-set time. When the set time interval is reached, the control system will start the screen walking operation even if the melt pressure has not yet reached the set value. This method is suitable for the melt pressure fluctuation is small, but need to regularly replace the filter screen production.

Third, the process of screen walking.

Heating: After triggering the screen walking action, the control system will automatically start the heating bar at the outlet end of the filtering mesh belt for heating. The purpose of heating is to increase the temperature of the melt at the outlet end to reach a temperature that can make the filter mesh move smoothly, so that the impurities in the melt can be brought out of the screen changer with the filter mesh.

Screen walking: When the outlet end reaches the set temperature, the screen starts to move automatically under the pressure of the melt itself. Since the screen of the mesh belt type automatic screen changer is continuous, uninterrupted filtration can be realized during the screen walking process, which ensures the continuity of production.

Cooling and sealing: As the mesh moves, the impurities are taken out of the screen changer, and the pressure at the feed port of the screen changer will gradually drop. When the pressure drops to the normal working value, the control system will stop the heating of the electric heating rod at the outlet end, at this time the outlet end passes the cold water, so that the melt is cooled and solidified, thus realizing the sealing and preventing the melt from leaking.

Fourth, the cycle of work.

After completing a go-net operation, mesh belt automatic screen changer will continue to filter work, until again to meet the go-net triggering conditions, and so on and so forth, to realize the fully automatic process of screen changing.

In general, mesh belt type automatic screen changer uses melt pressure or time to control the action of walking screen, with the automatic process of changing the screen, material pressure and material flow fluctuation is small, product quality and stability, etc., is mainly used for chemical fiber spinning, drawing, tubing, blown film, cast film, laminating film, sheet, sheet, pelletizing and other high-quality, long-process product production, especially adapted to pressure fluctuations in the production of high-precision products that require strict requirements. It is especially suitable for the production of high-precision products with strict requirements for pressure fluctuation.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447