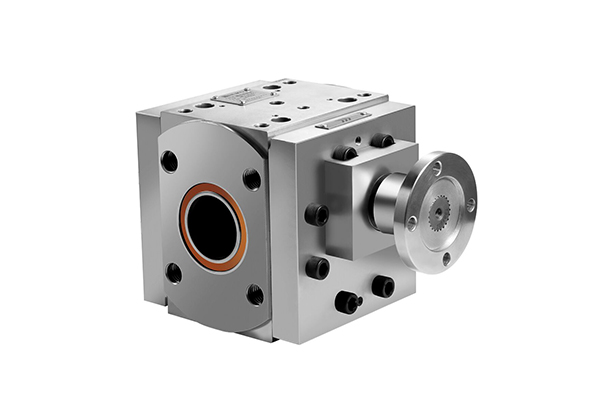

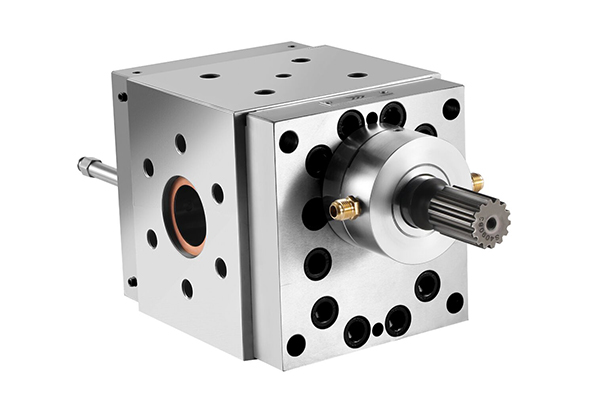

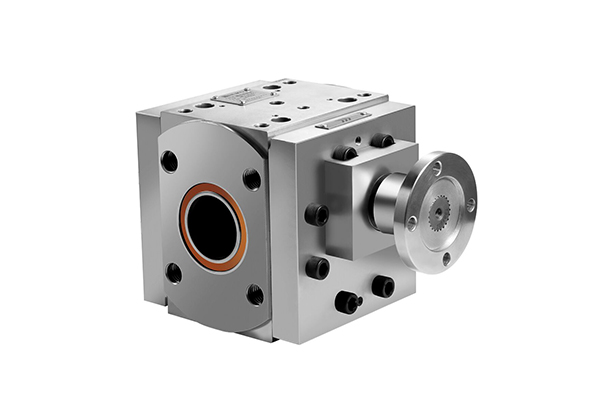

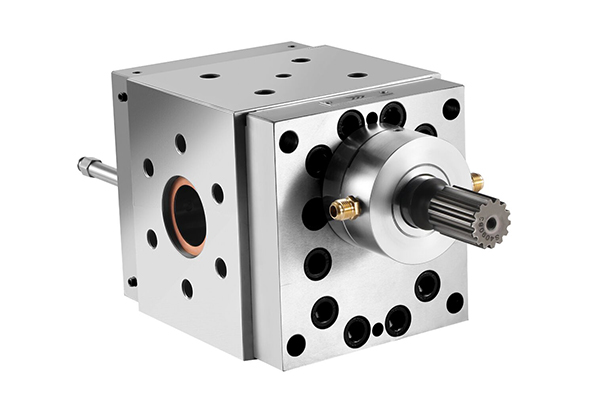

Compact and precise structure: the melt pump's structural design is usually compact and occupies less space, which is convenient for installation and layout in the production line. At the same time, its high manufacturing precision ensures the wear resistance and durability of the pump body, which can operate stably for a long time under the harsh environment of high temperature and high pressure.

Efficient and stable conveying: The melt pump can convey PVDF fluoroplastic melt efficiently and stably, ensuring stable flow and pressure during the extrusion process. This helps to reduce production fluctuations and improve the quality of extruded products and product precision.

Strong adaptability: the melt pump is suitable for different types and specifications of PVDF fluoroplastic materials, which can meet different production requirements. Meanwhile, it is also able to adapt to harsh production environments such as high temperature and high pressure, which ensures the continuity and stability of production.

Precise metering and control: Melt pumps have precise metering function, which can realize accurate metering and delivery of melt. In addition, modern melt pumps are usually equipped with intelligent control systems, which can monitor and adjust the working status of the pumps in real time and improve the production efficiency and automation level.

Wear-resistant and corrosion-resistant: Since PVDF fluoroplastics have excellent corrosion and wear resistance, melt pumps also have excellent wear-resistant and corrosion-resistant performance when conveying PVDF fluoroplastics melts, which prolongs the service life of the equipment.

Stable pressure: The melt pump can effectively buffer and compensate for the fluctuation of the melt pressure and flow rate output from the extruder, ensuring that the melt enters the subsequent process in a stable state, thus improving the dimensional accuracy and surface quality of the extruded products.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447