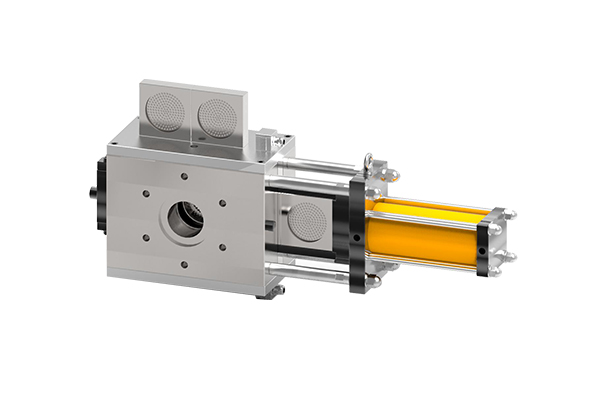

Hydraulic slide plate screen changer is a commonly used equipment in plastic extrusion production, the following is its relevant introduction:

Hydraulic slide plate screen changer working principle

Two parallel slide plate inserted into the screen changer body, each slide plate has a round filtering station. High-temperature melt into the screen changer is divided into two channels, at the same time through the two filters, and then in the screen changer in the closing flow through the exit into the mold. When the accumulation of impurities on the filtering screen causes the pressure alarm to alarm, it is necessary to carry out the screen changer operation. Operate the hydraulic station handle button to start the hydraulic station, push one of the slide plate displacement, so that the filtering workplace moved out of the main body, the other slide plate of the filtering workplace continue to work. Turn off the hydraulic station, clean and replace the filter screen of the filtering station moved out of the main body, replace it with a new screen, and then start the hydraulic station again to pull the slide plate back to work in the main body. Then the other slide plate to carry out the same net change operation, after the completion of the two slide plate filtration workstation are back to normal work, to achieve non-stop net change.

Hydraulic slide plate screen changer performance characteristics

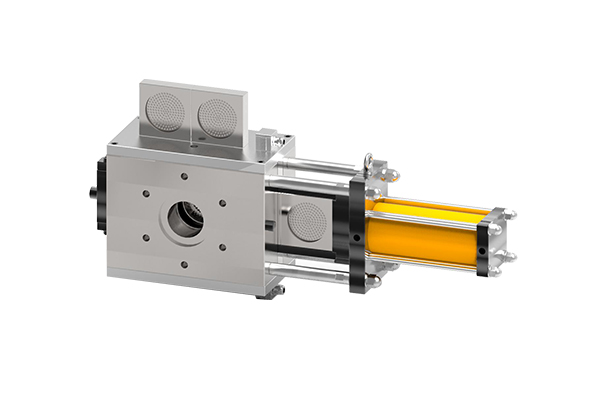

Good production continuity: Adopting double-station design, one station works and the other one changes the mesh when changing the mesh, so that the mesh can be changed quickly without stopping the machine, reducing the production interruption time and improving the production efficiency.

Excellent sealing performance: It adopts pressure activated sealing structure, maintenance-free wear-resistant sealing ring and other sealing designs. It can ensure that there is no leakage of material under the conditions of working temperature up to 300℃ and melt pressure up to 40MPa, preventing material leakage and ensuring product quality and clean production environment.

Large filtration area: double filters work at the same time, the filtration area is usually two times that of a single net, which can meet the production requirements of higher quality and higher output, effectively retaining the impurities and foreign matter in the plastic melt and improving product quality.

Strong process adaptability: it is suitable for a variety of plastic raw materials, such as PP, PE, ABS, PS, etc., as well as the production of sheet, plate, pipe, blown film and other products, and has good adaptability to different extrusion processes and product requirements.

Easy operation: operated by the handle button of the hydraulic station, it controls the movement of the slide plate and realizes the process of screen changer, which is simple and convenient to operate and easy to be mastered by the workers. At the same time, some screen changers can be equipped with protective cover to prevent pinching and scalding, improve operational safety.

Energy saving and high efficiency: some hydraulic slide plate screen changers adopt internal heating method with high thermal efficiency, which can effectively utilize thermal energy and reduce energy consumption. Some models are also equipped with pressure adaptive system, which can dynamically adjust the output of the hydraulic pump to achieve energy-saving effect.

Hydraulic slide plate screen changer is widely used in various production lines in the plastic extrusion industry, such as pelletizing production line, which can be used to filter impurities in plastic granules to improve the purity and quality of the granules; in the production of tubes, it can ensure the inner wall of the tubes to be smooth, to avoid the impact of impurities on the performance and appearance of the tubes; in the production of blown film, sheet and plate, it can ensure the quality of surface of the film and plate to reduce the imperfections and blemishes. In addition, it is also suitable for the production of hollow products, laminating film, cast film and other production fields, which is one of the important equipments to improve product quality and production efficiency in plastic extrusion production.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447